Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

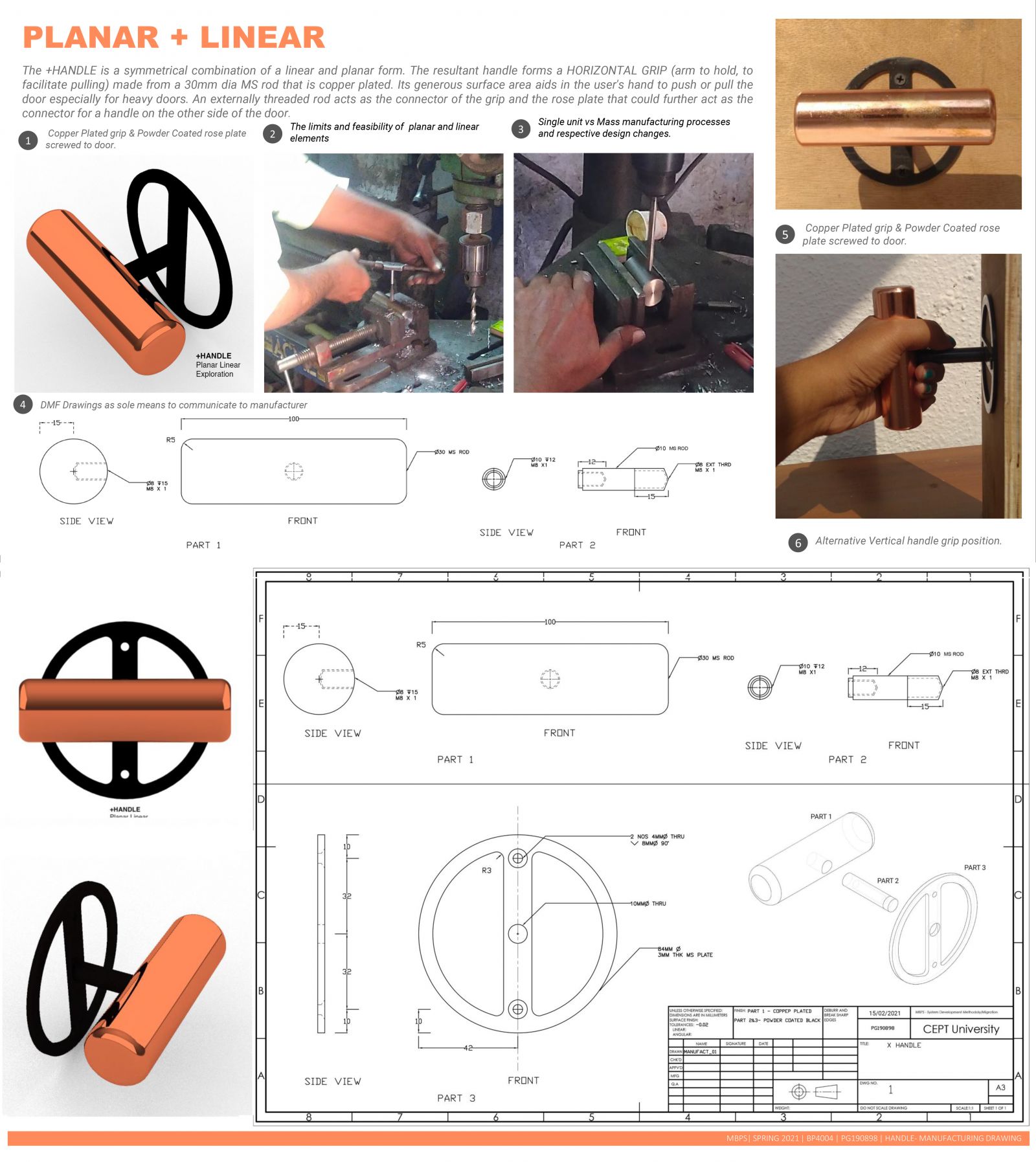

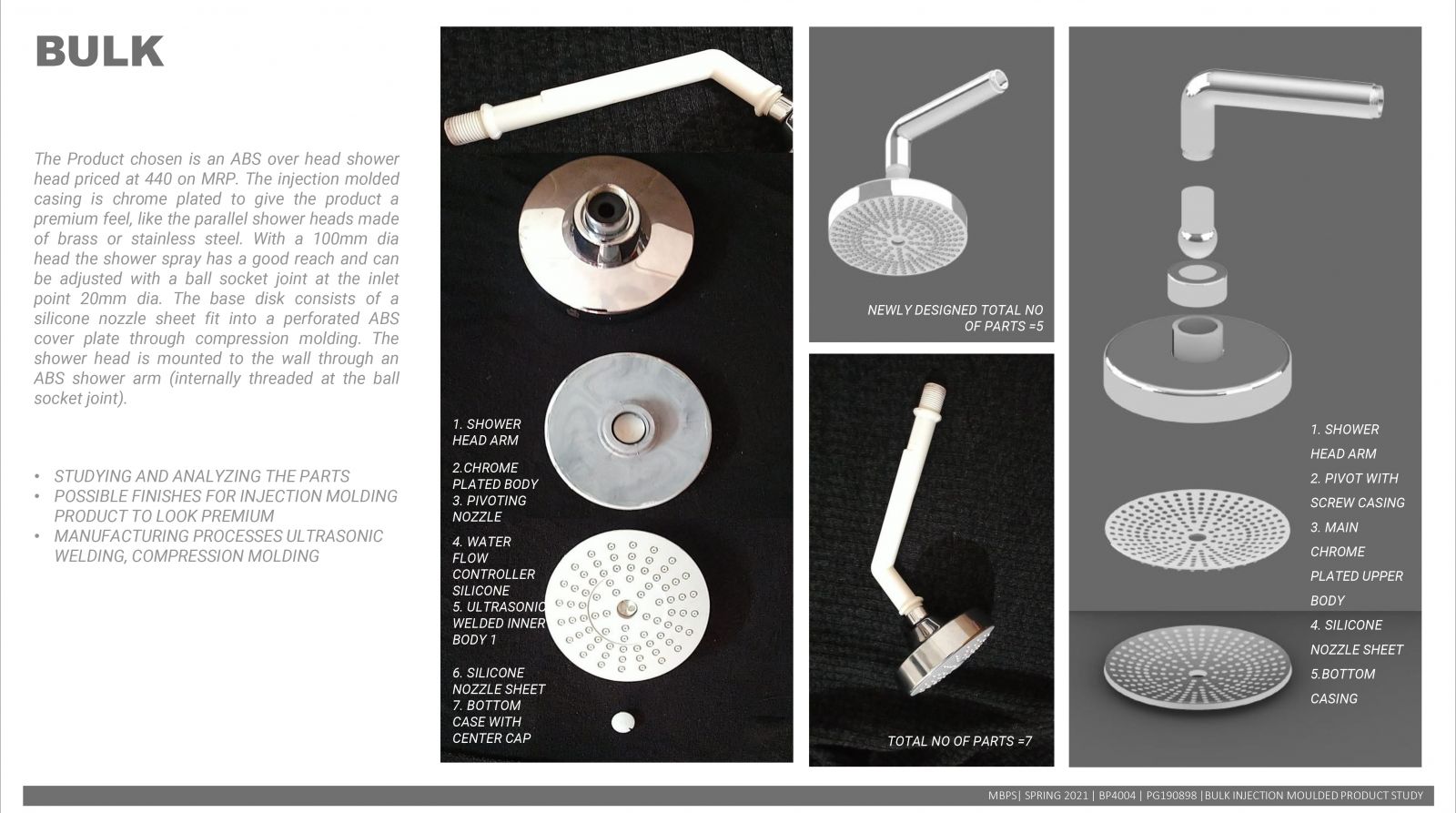

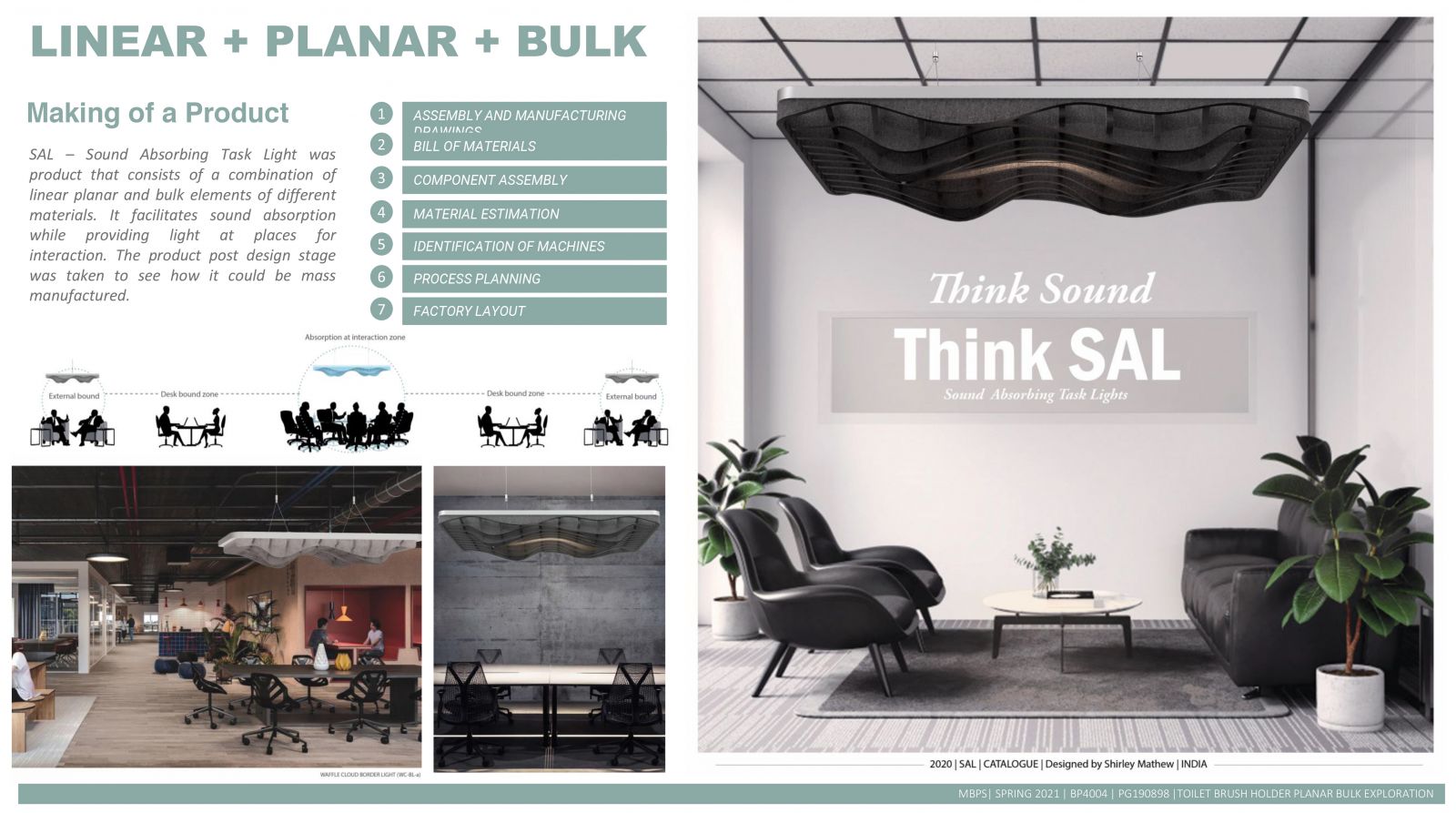

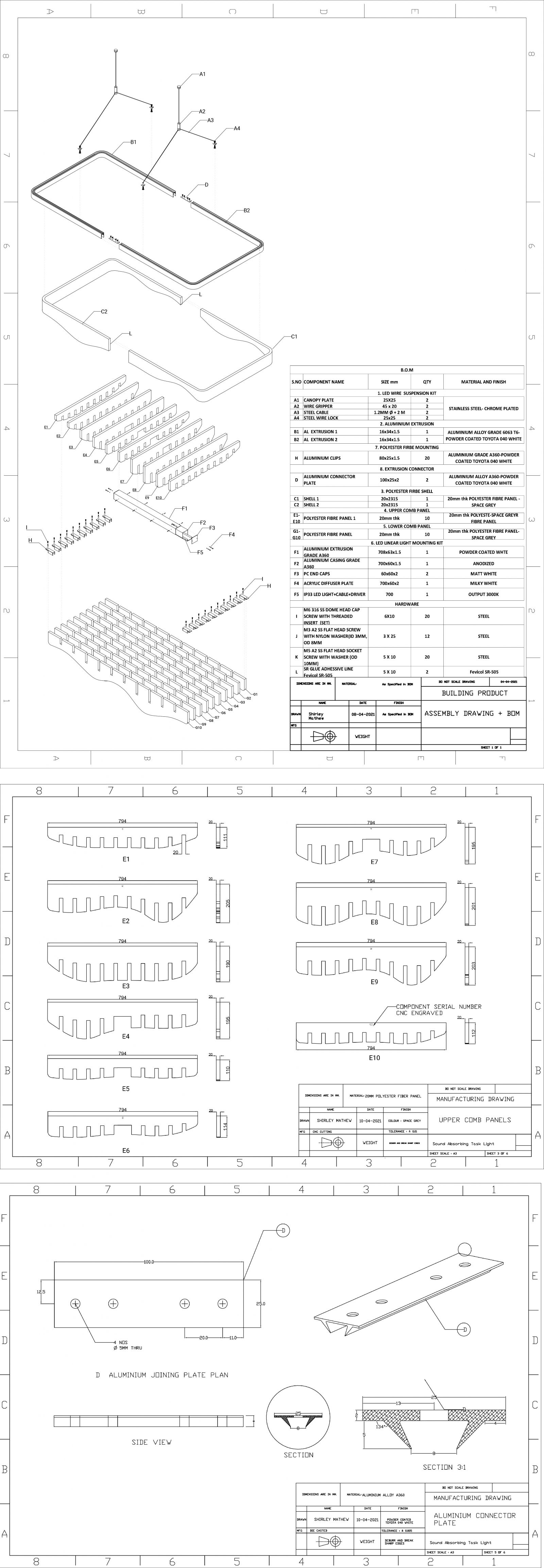

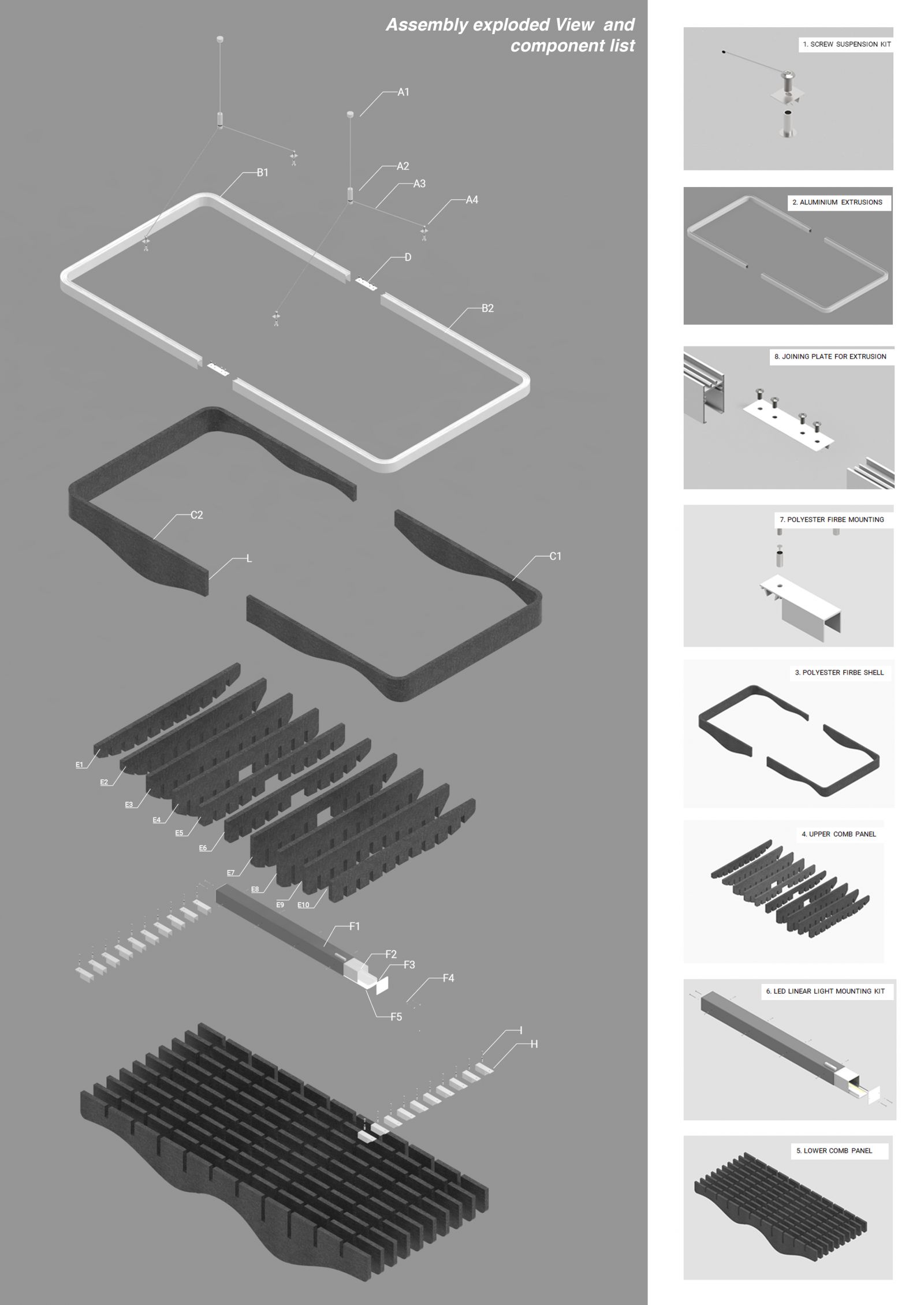

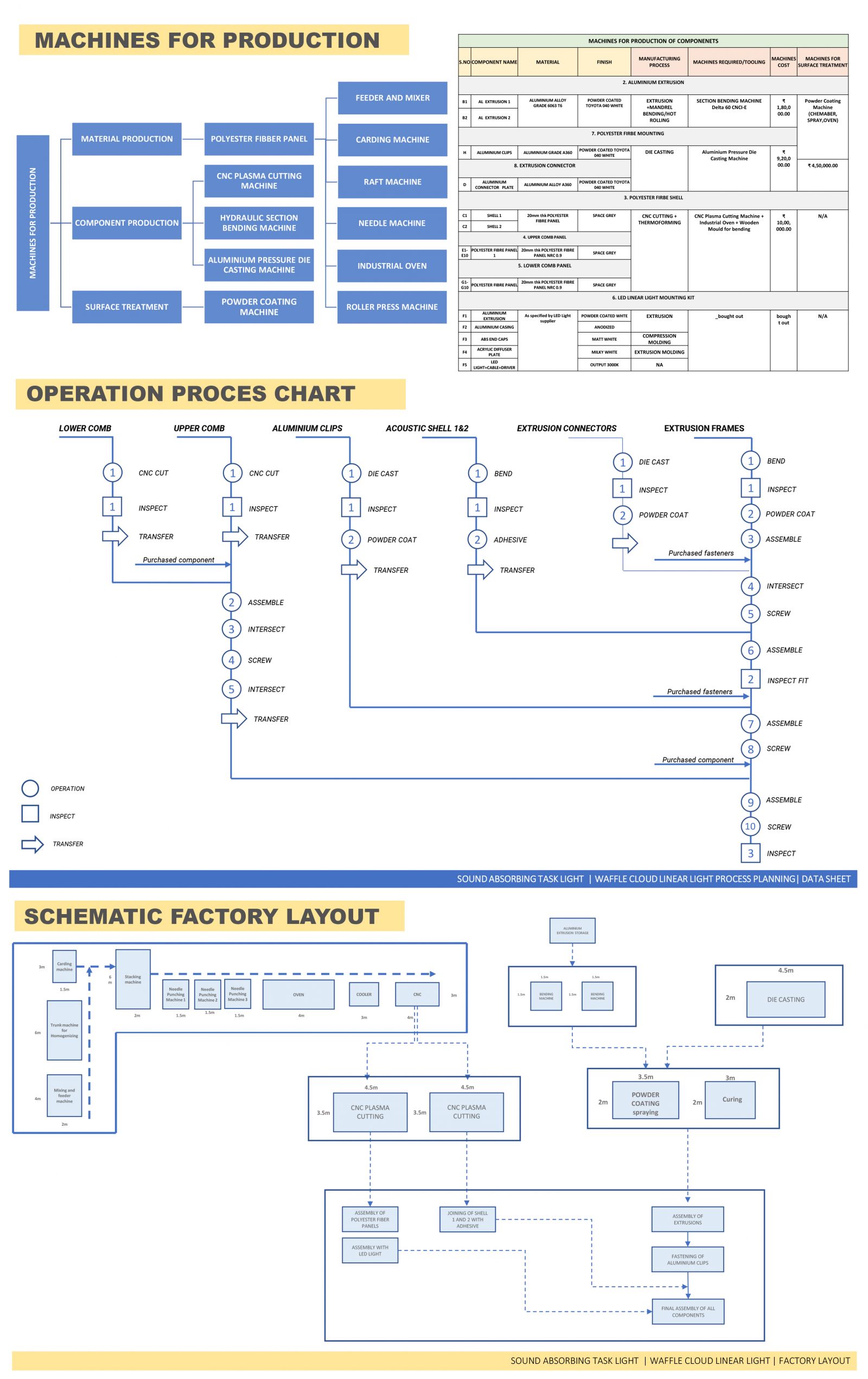

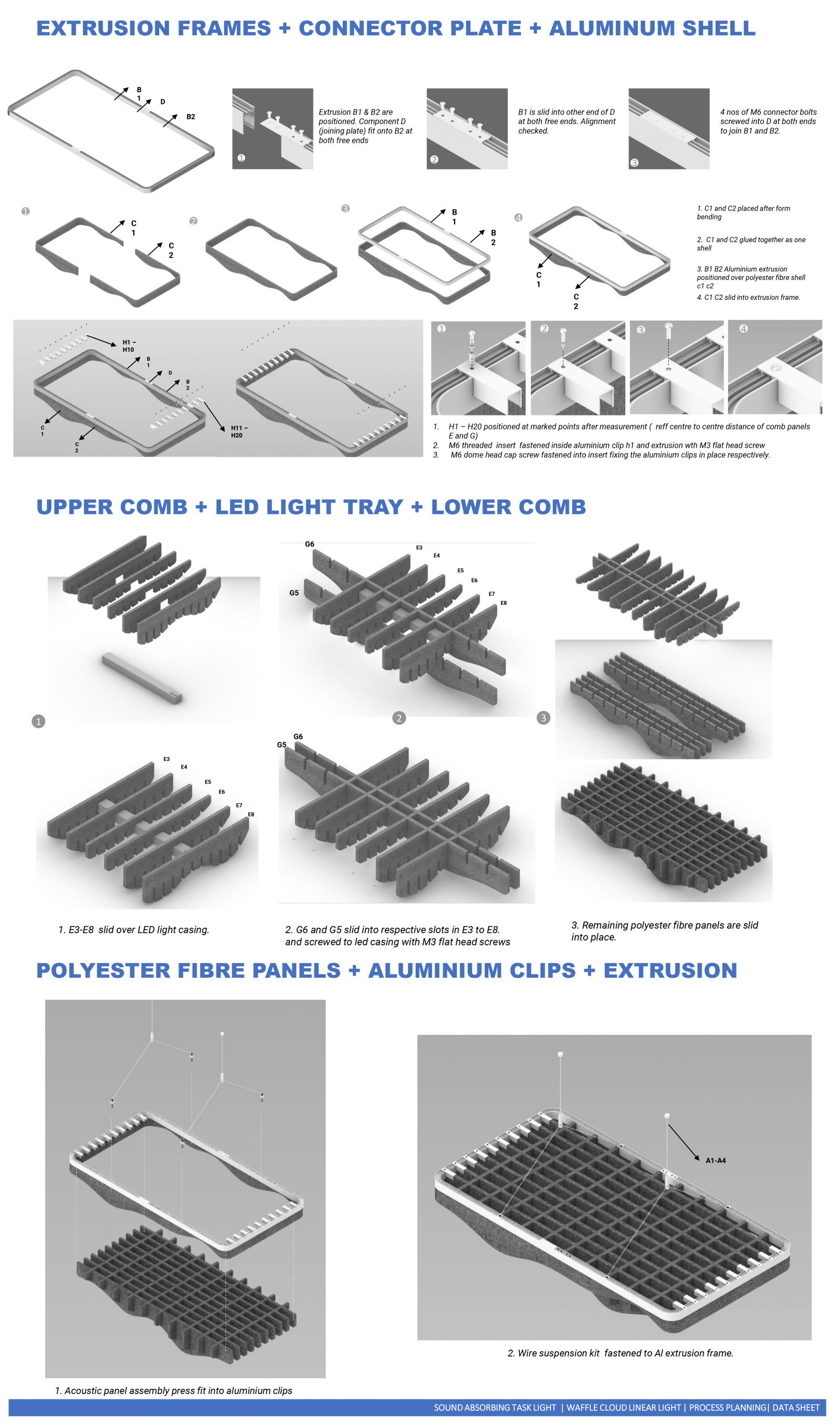

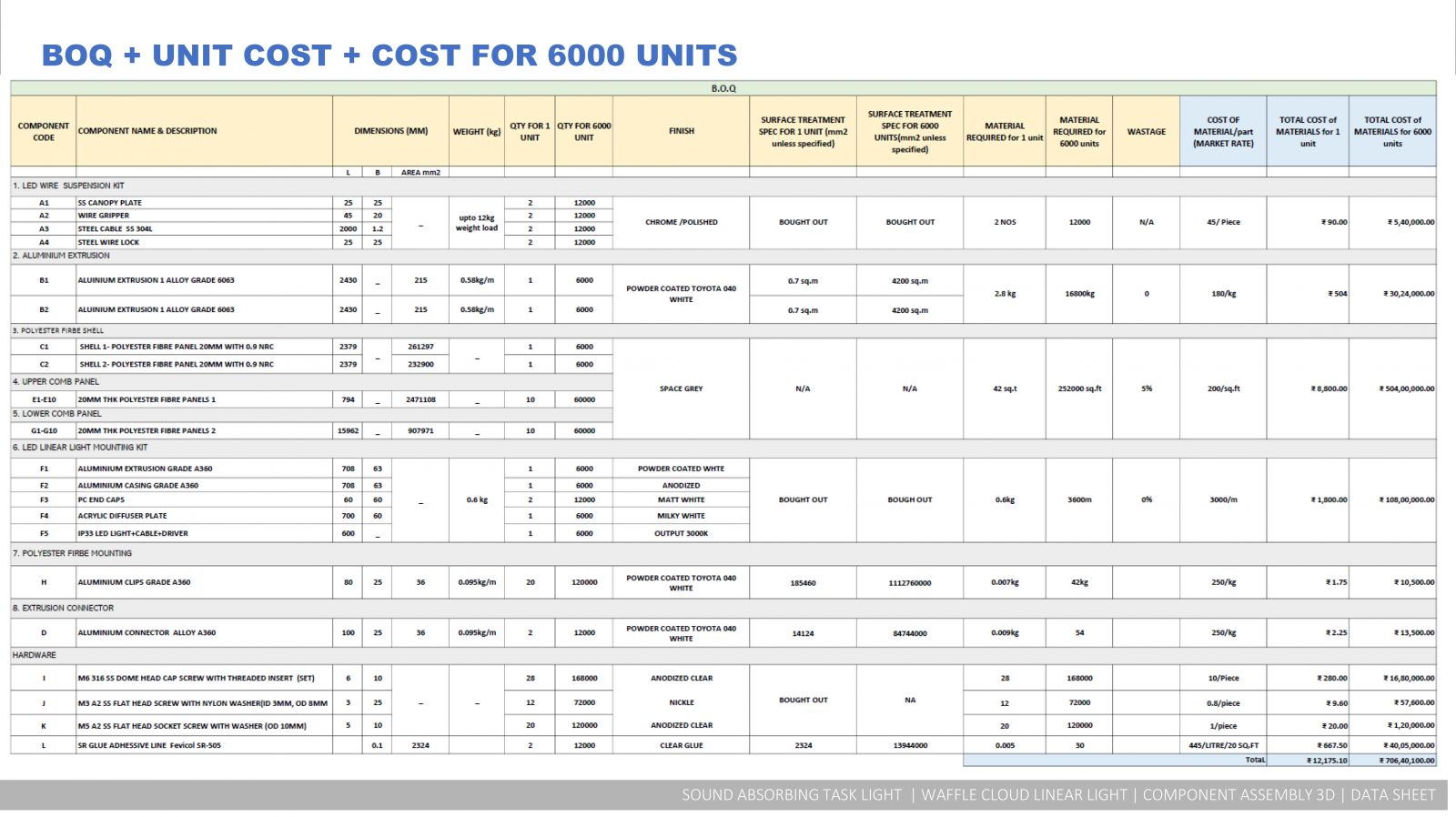

This studio aimed at understanding different concepts in manufacturing of a product right from forms of materials, their manufacturing process upto the factory layout for a mass produced building product.

View Additional Work