Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

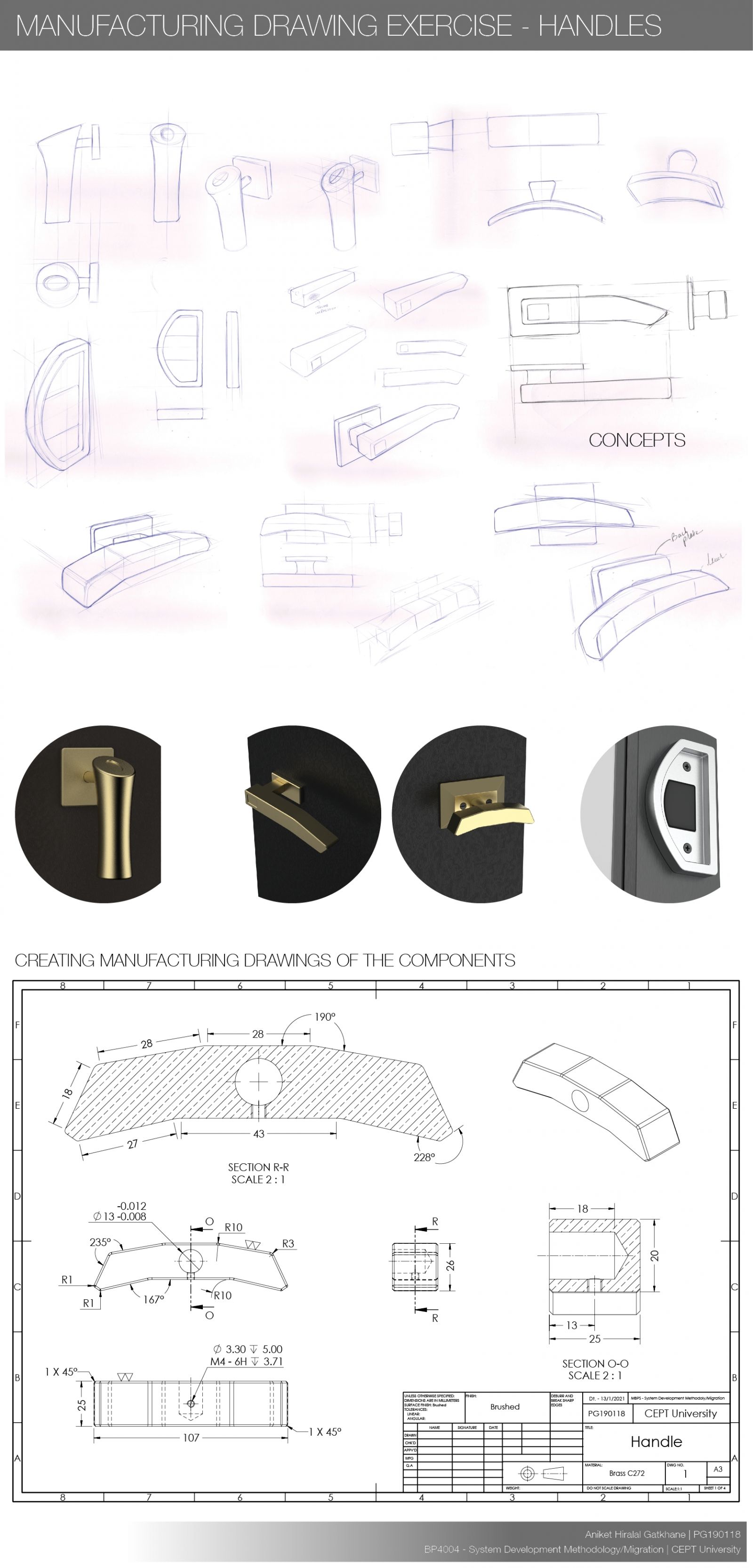

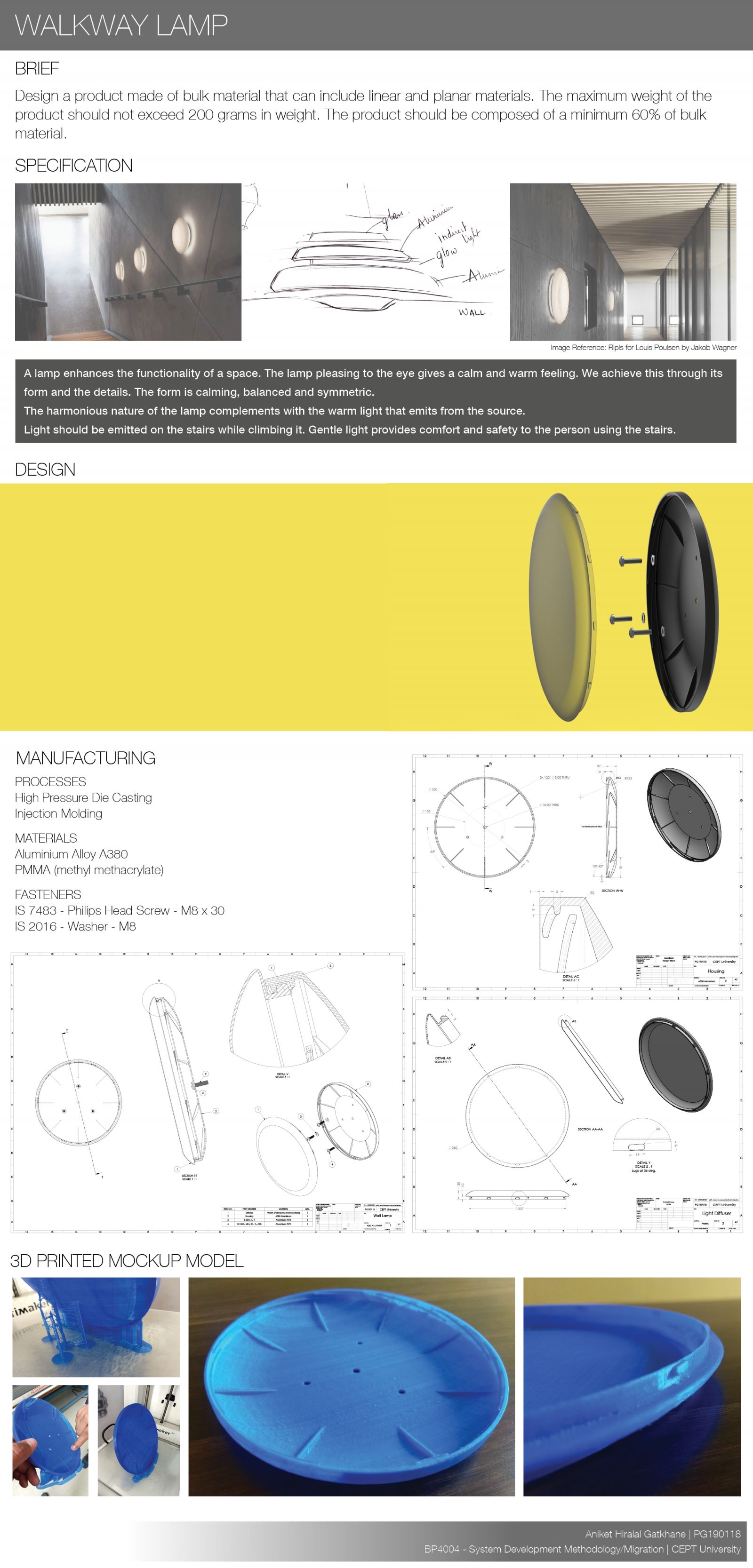

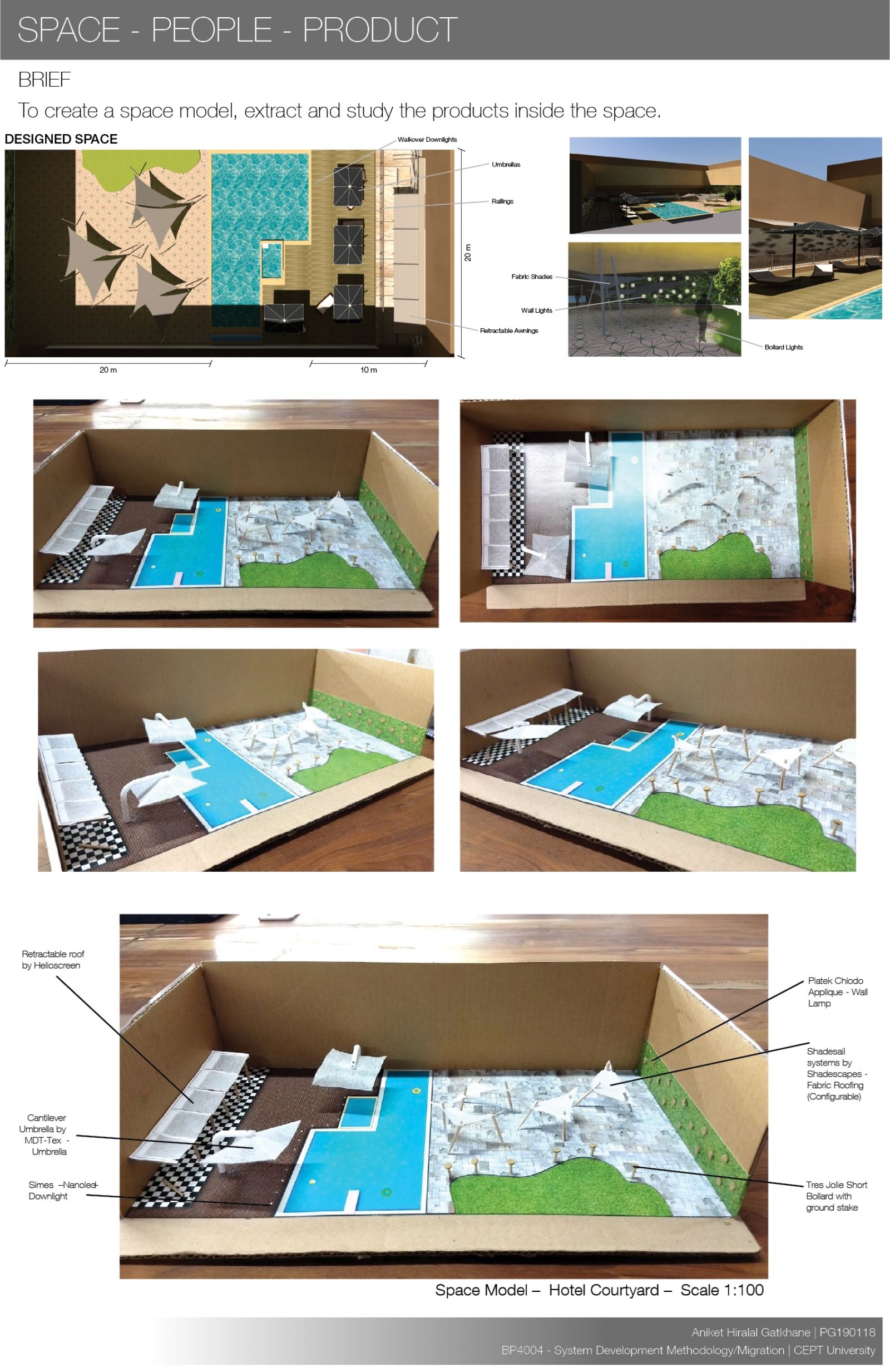

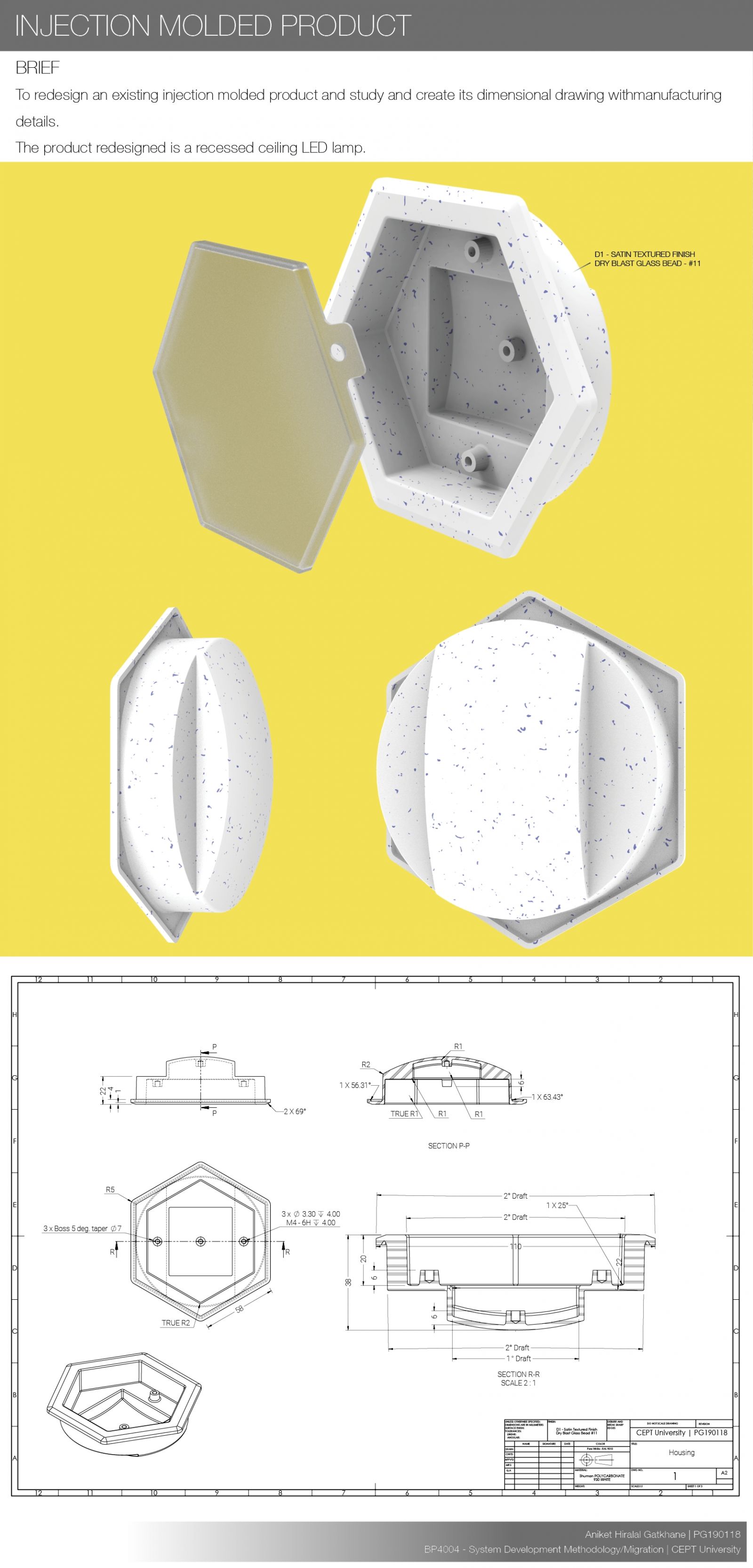

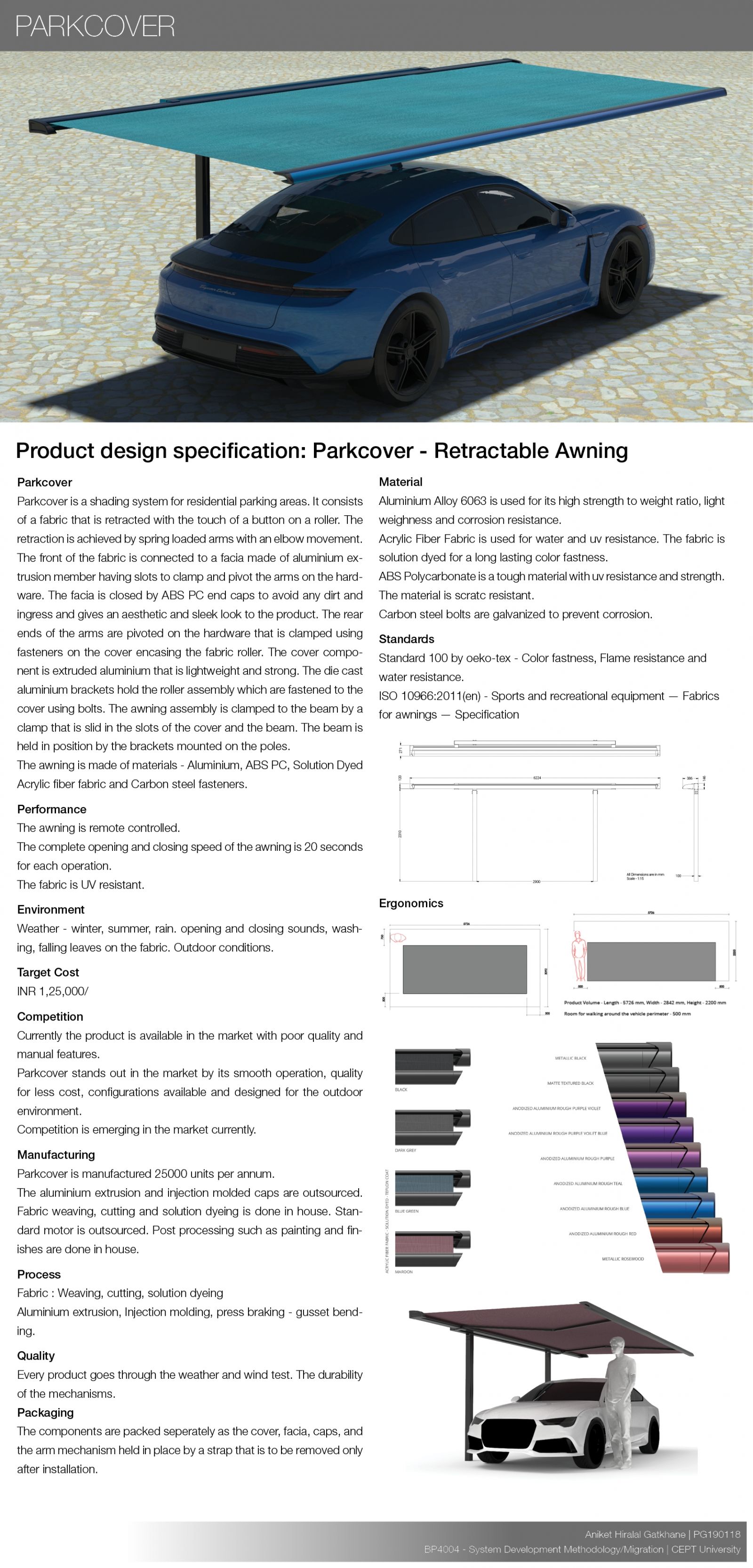

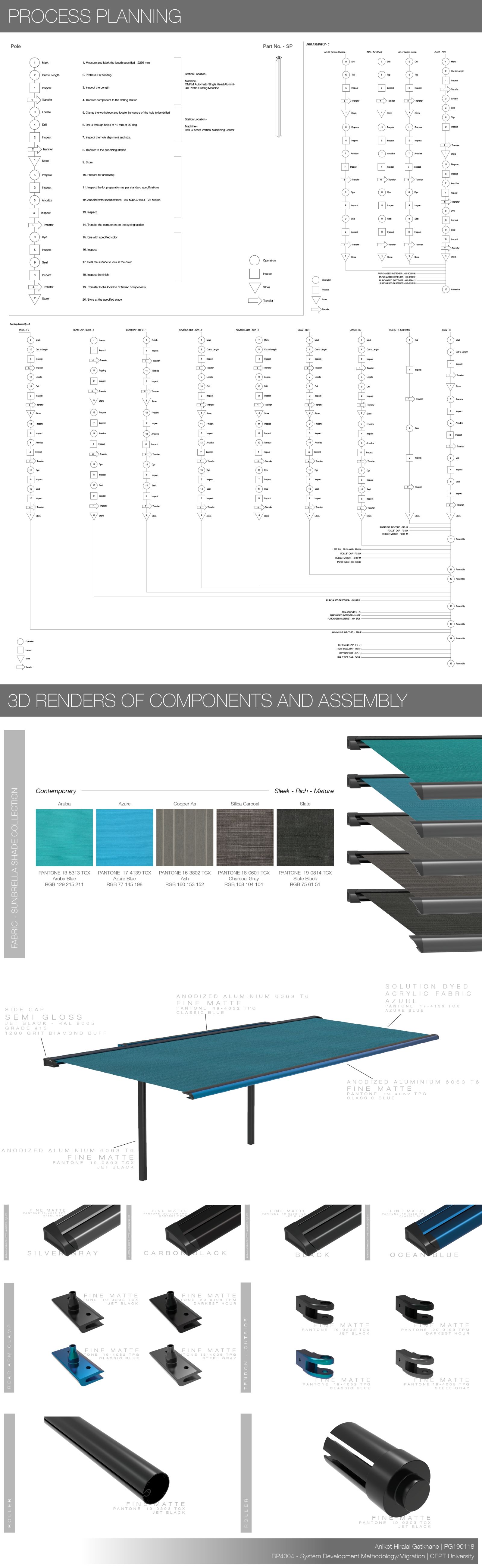

The studio journey started with understanding and creating manufacturing details through designing handles. It progressed through understanding different forms of materials such as linear, planar & bulk, and designing products such as a handle using linear & planar materials and wall lamp using bulk materials. A space model comprising all the products with respect to Space | People | Products system was designed to understand the scale and manufacturing of the products. Product designed for specifically injection molding process. The major exercise was to culminate all the learnings into mass manufacturing a product.