Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

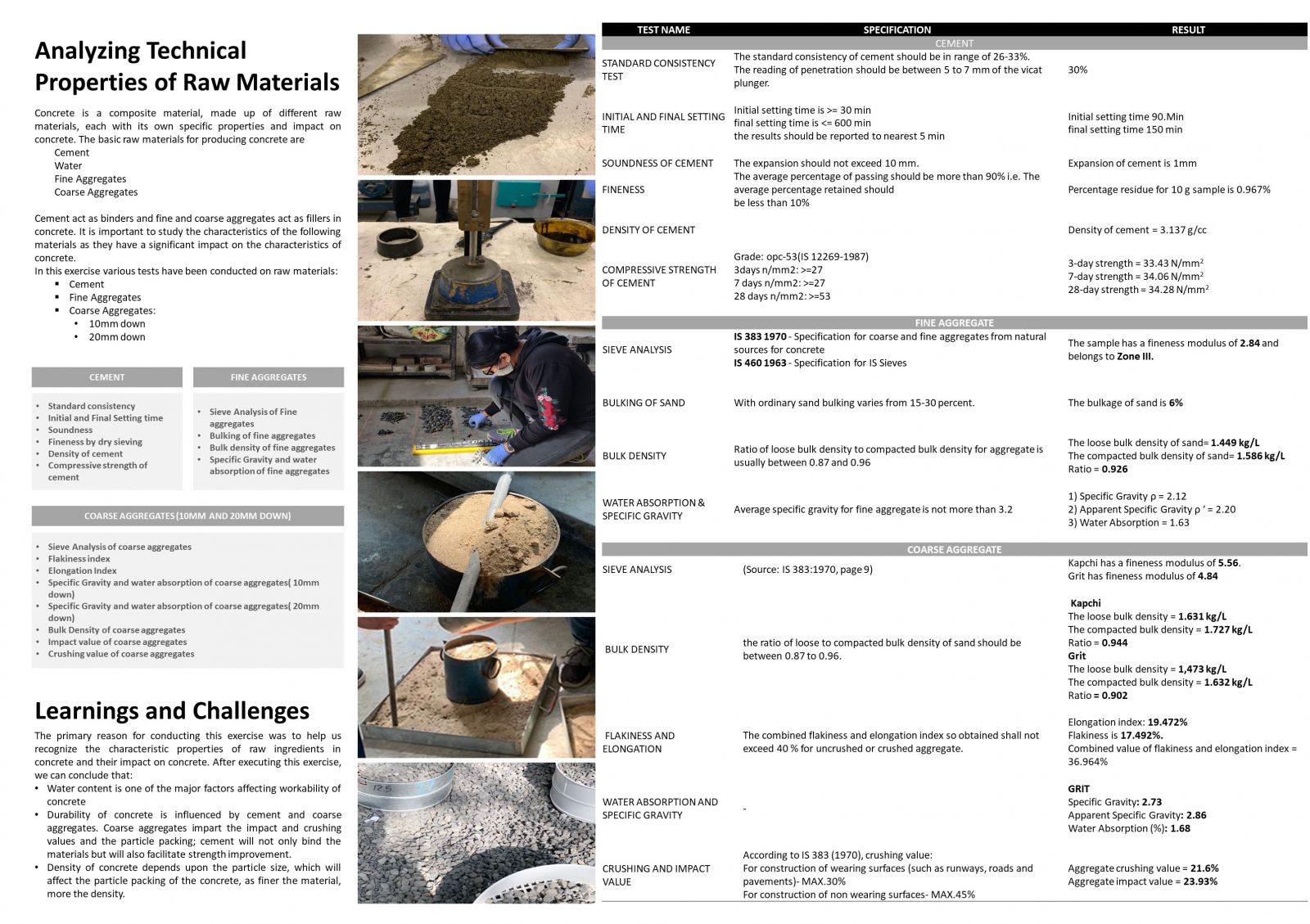

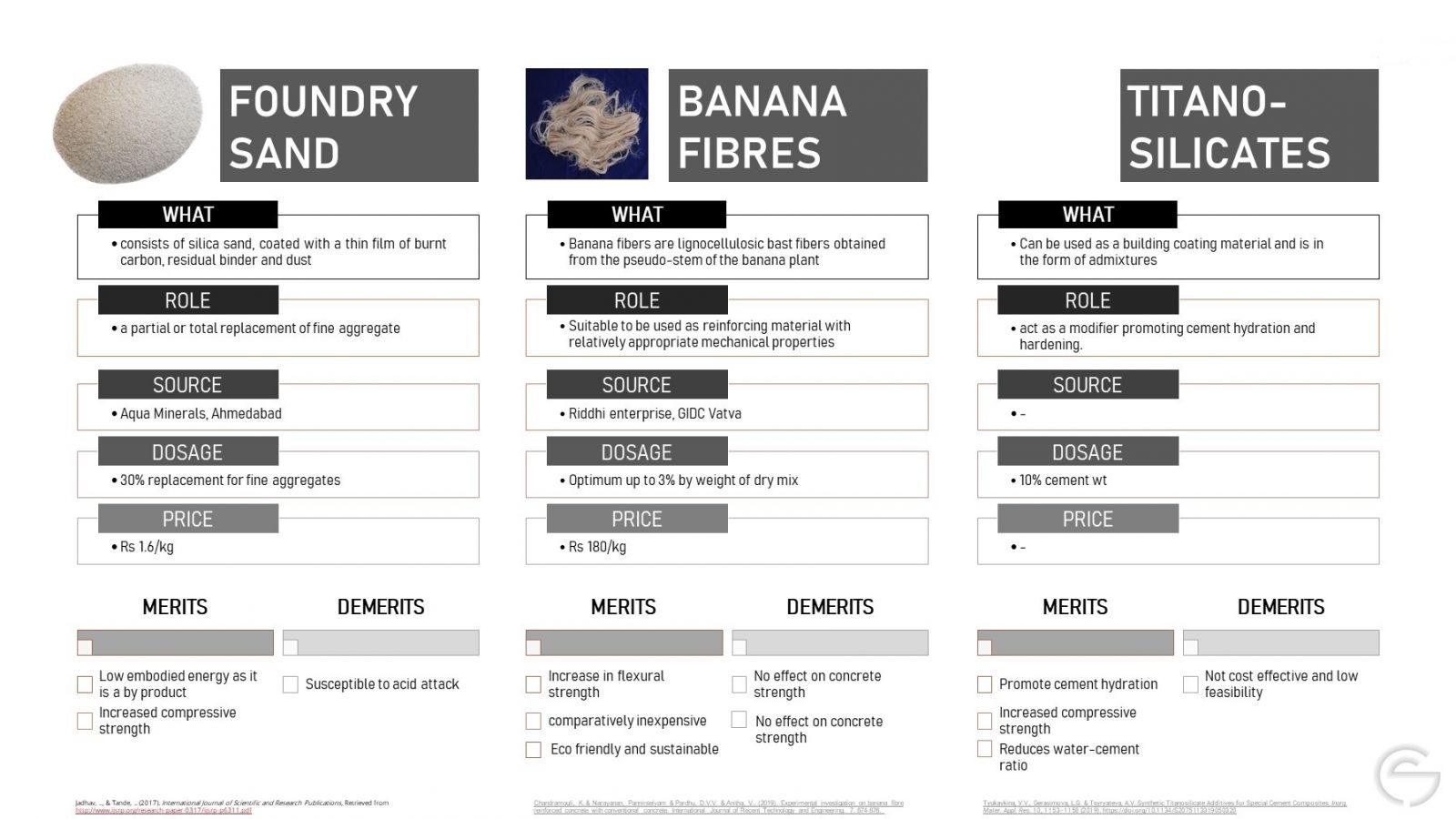

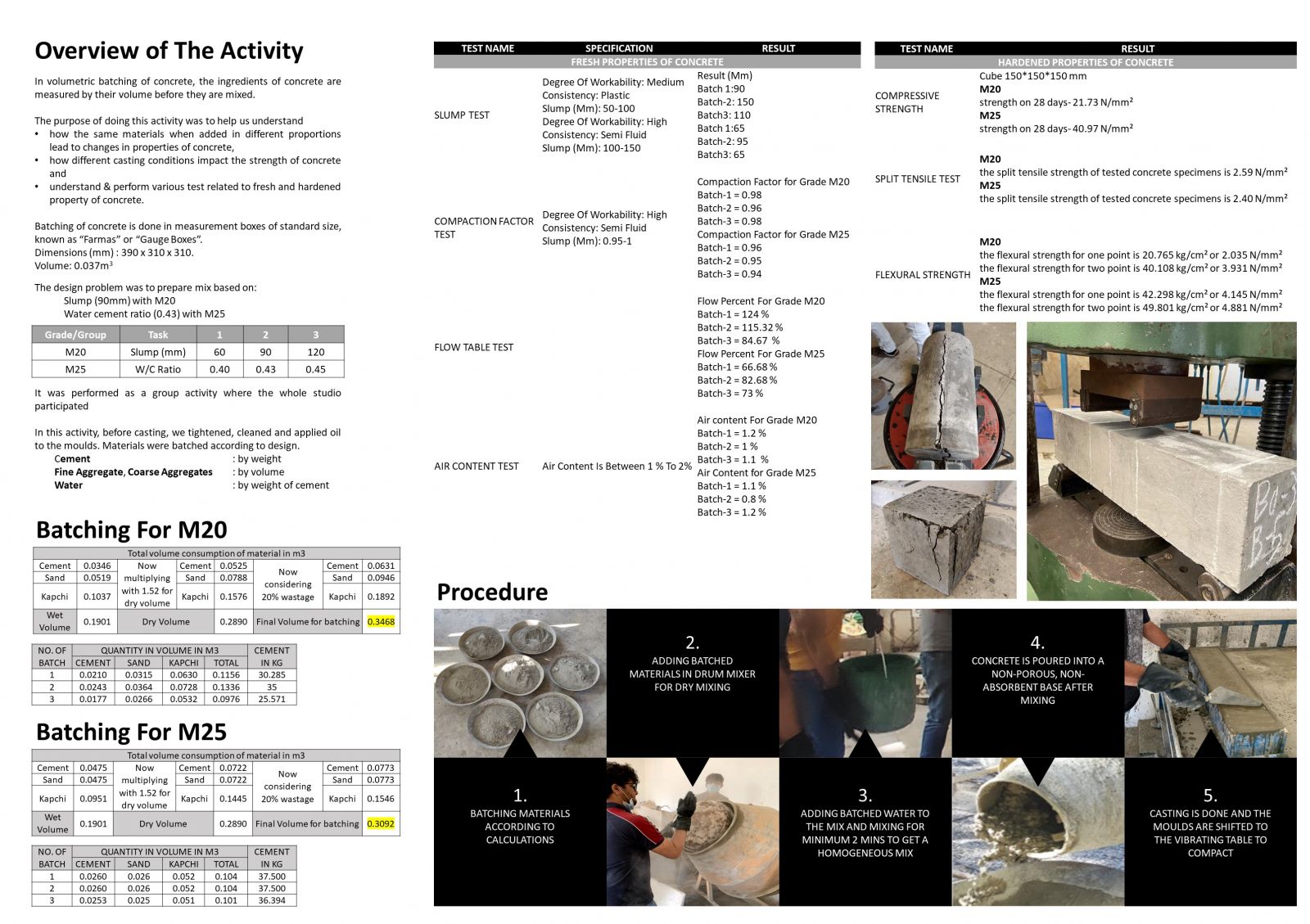

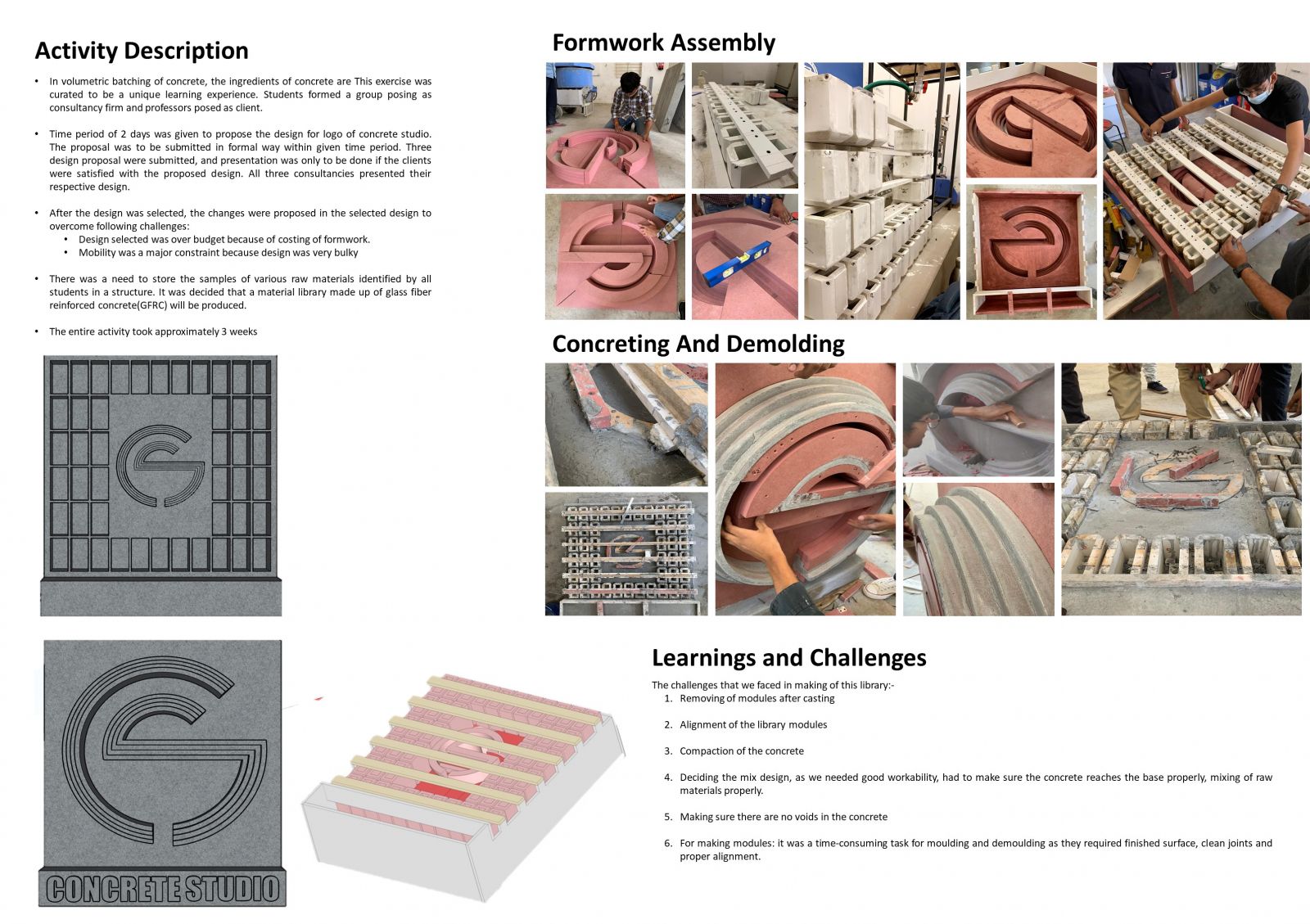

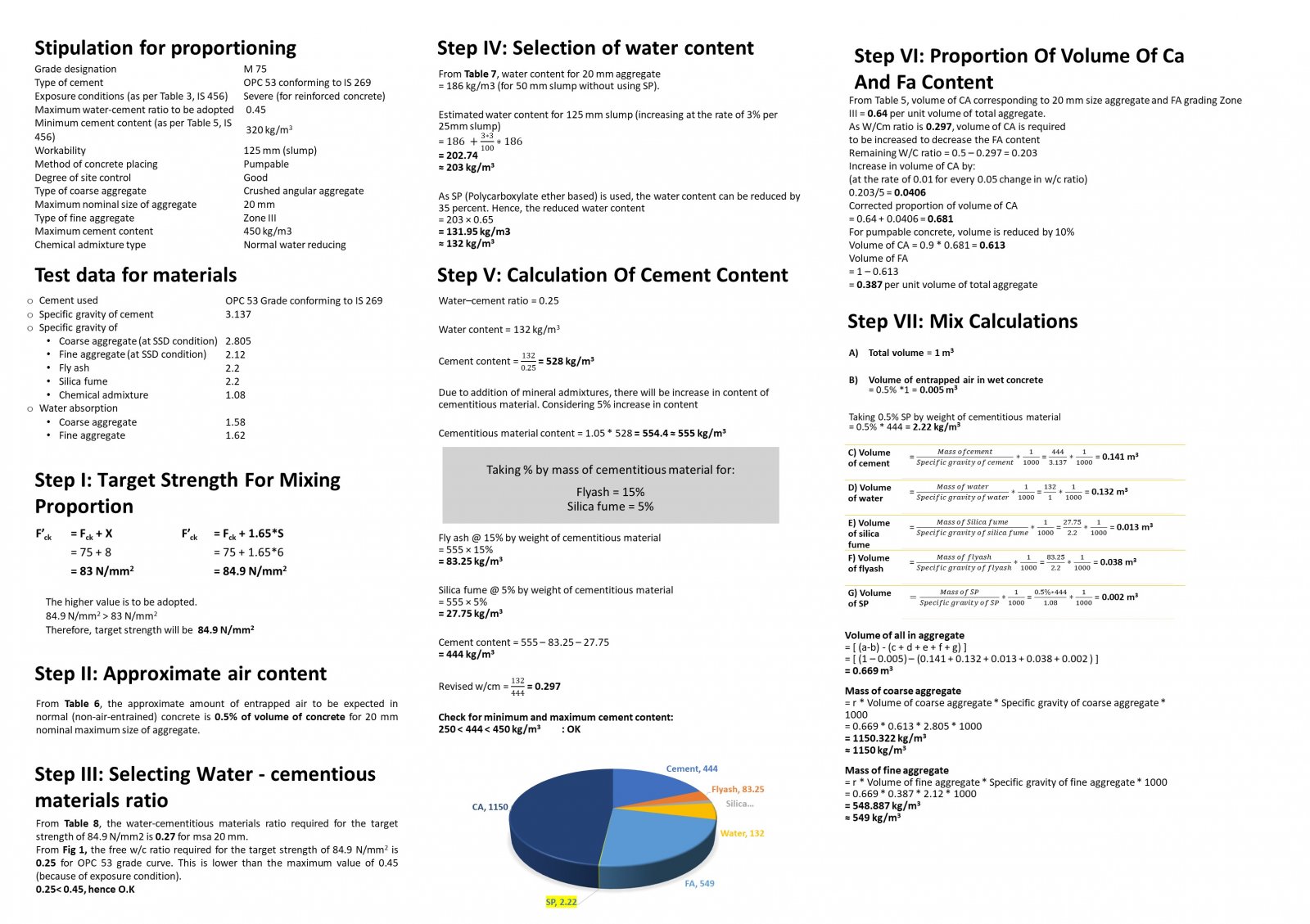

In this studio, we performed many exercises, each with its own challenges and learning. While working with raw materials, we got to analyze the behavior of a material and its quality. Moving on to concreting, we performed volumetric batching. While concreting we made 2 different grades of concrete with the different problem statement. We had to make M20 for a specific slump and M25 for a specific w/c ratio. From that, we got to know about the quantity of material used and their effect to produce the required workability and result. Next, we had to find new materials that can be used in concrete to enhance its property. For the pilot project, we had were divided into 3 groups, each posing as a consultancy and proposing a logo for the studio. It cultivated our skills to bargain, submit proposals, effective teamwork, and communication. After finalizing the logo, we included a material library in the logo itself, which served the dual purpose of displaying materials and the logo. An overall understanding of the various processes involved in the erection of a structure like making formwork, designing the concrete, how to enhance its workability, and make it self compacting was gained. We were taught about mix design and then had to design a high-strength concrete mix based on the parameters assigned. After that, we worked on our special concrete. Developing a special concrete proposal made us realize the various factors considered while developing it. By engineering concrete into special concrete the knowledge of identifying, analyzing, and overcoming basic problems of concrete was gained.

View Additional Work