Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

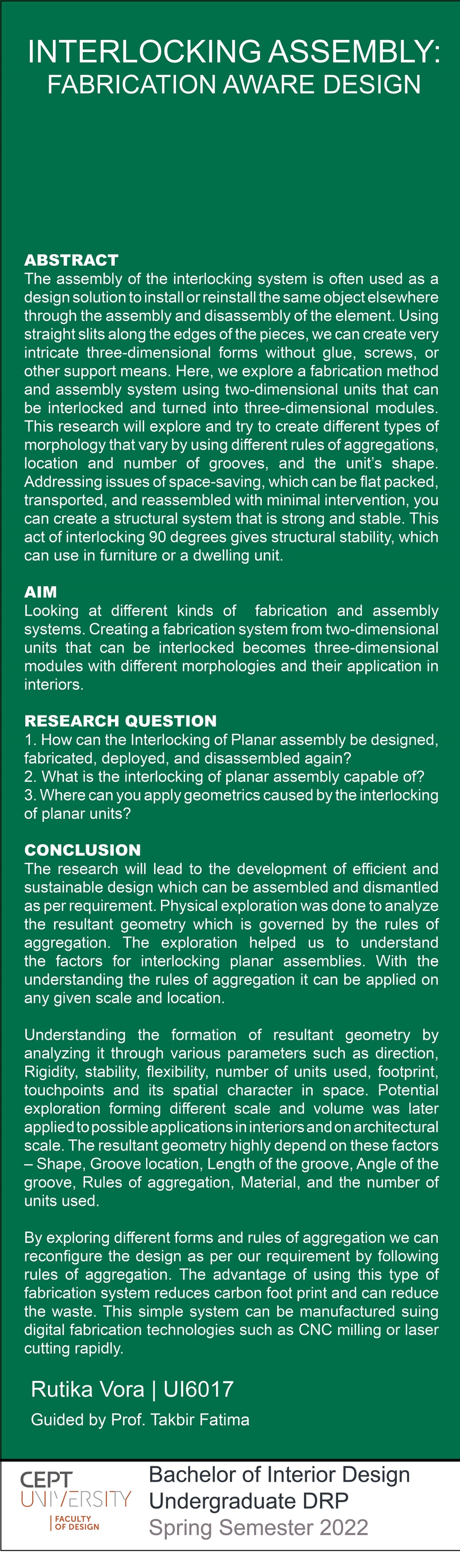

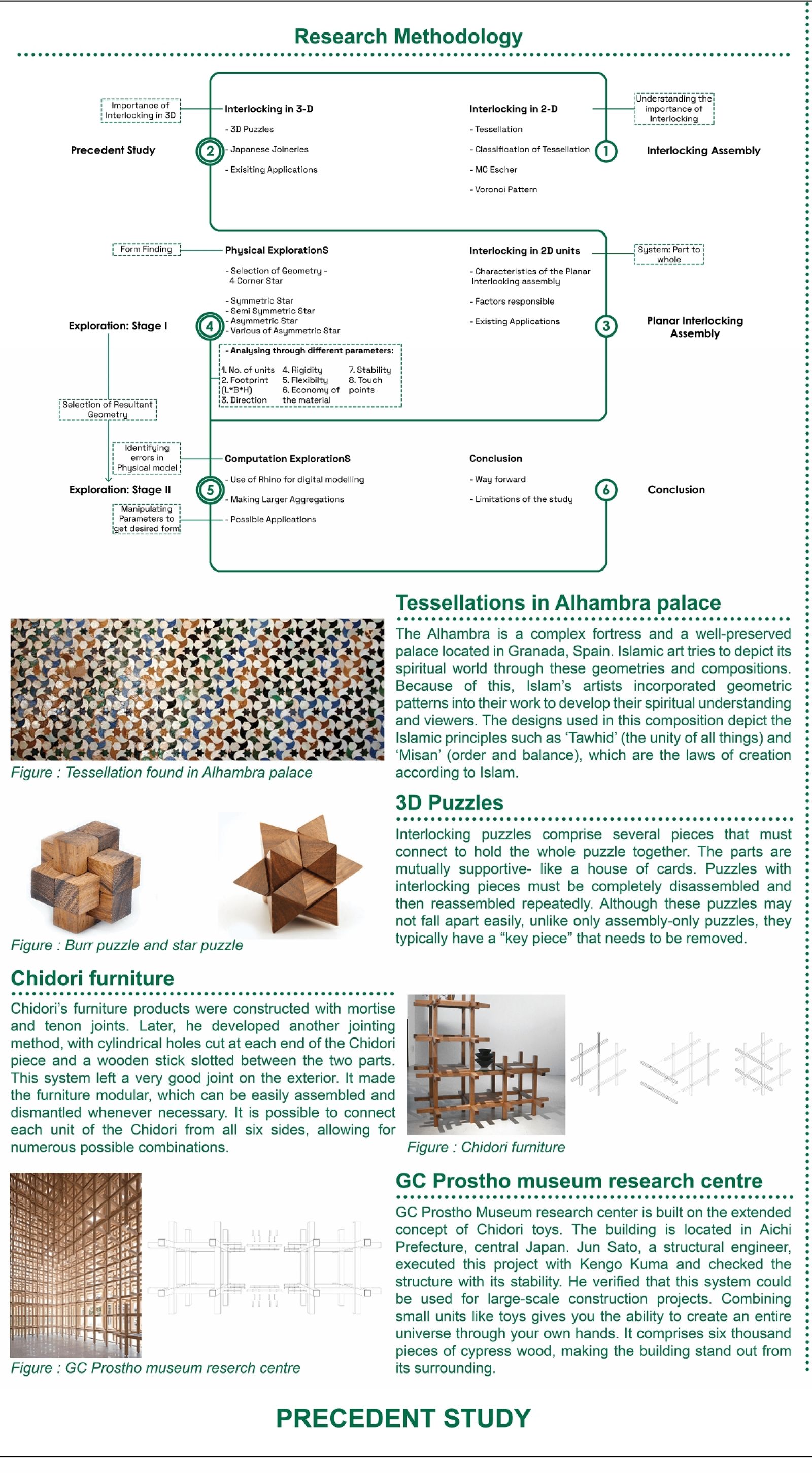

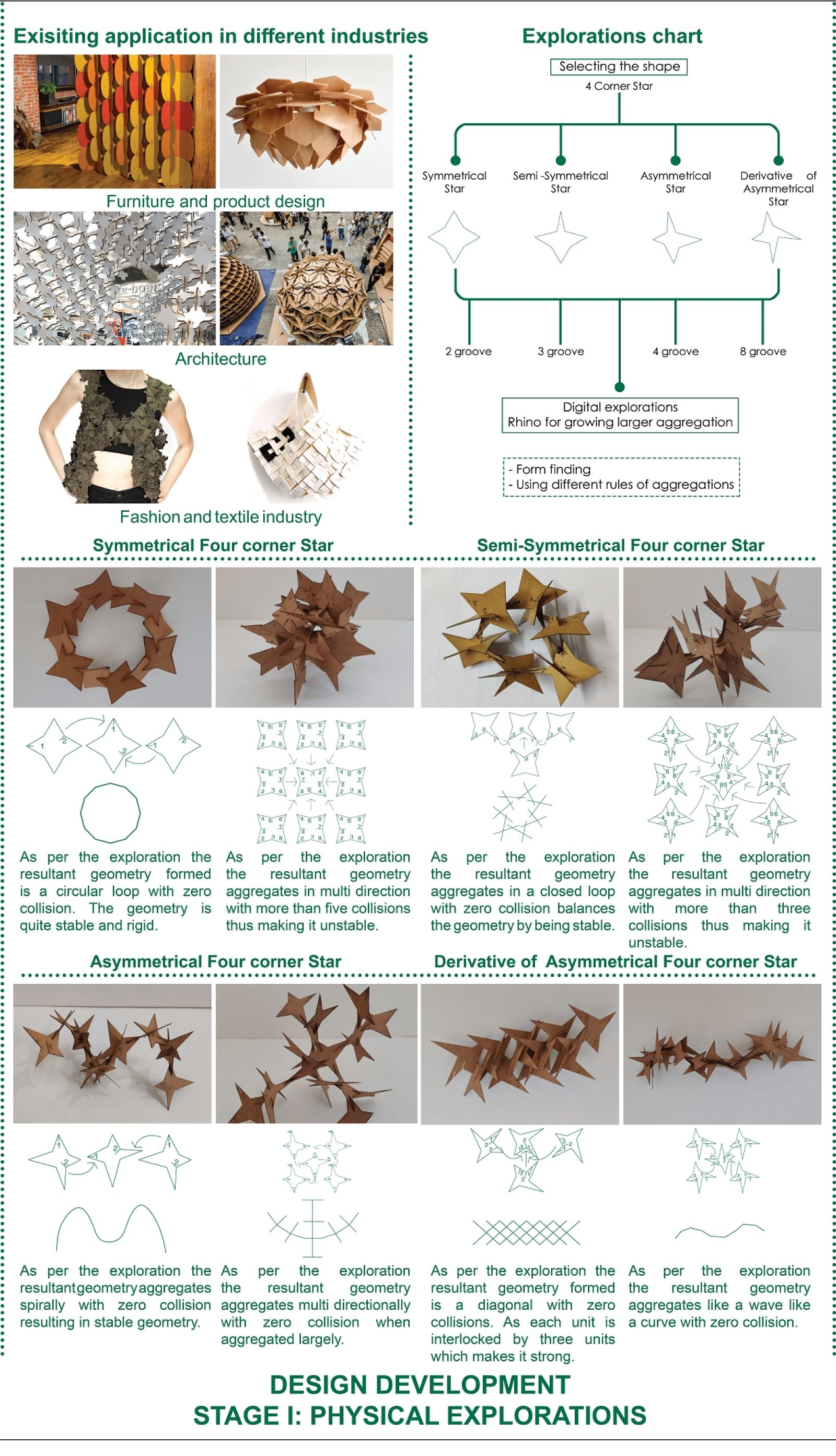

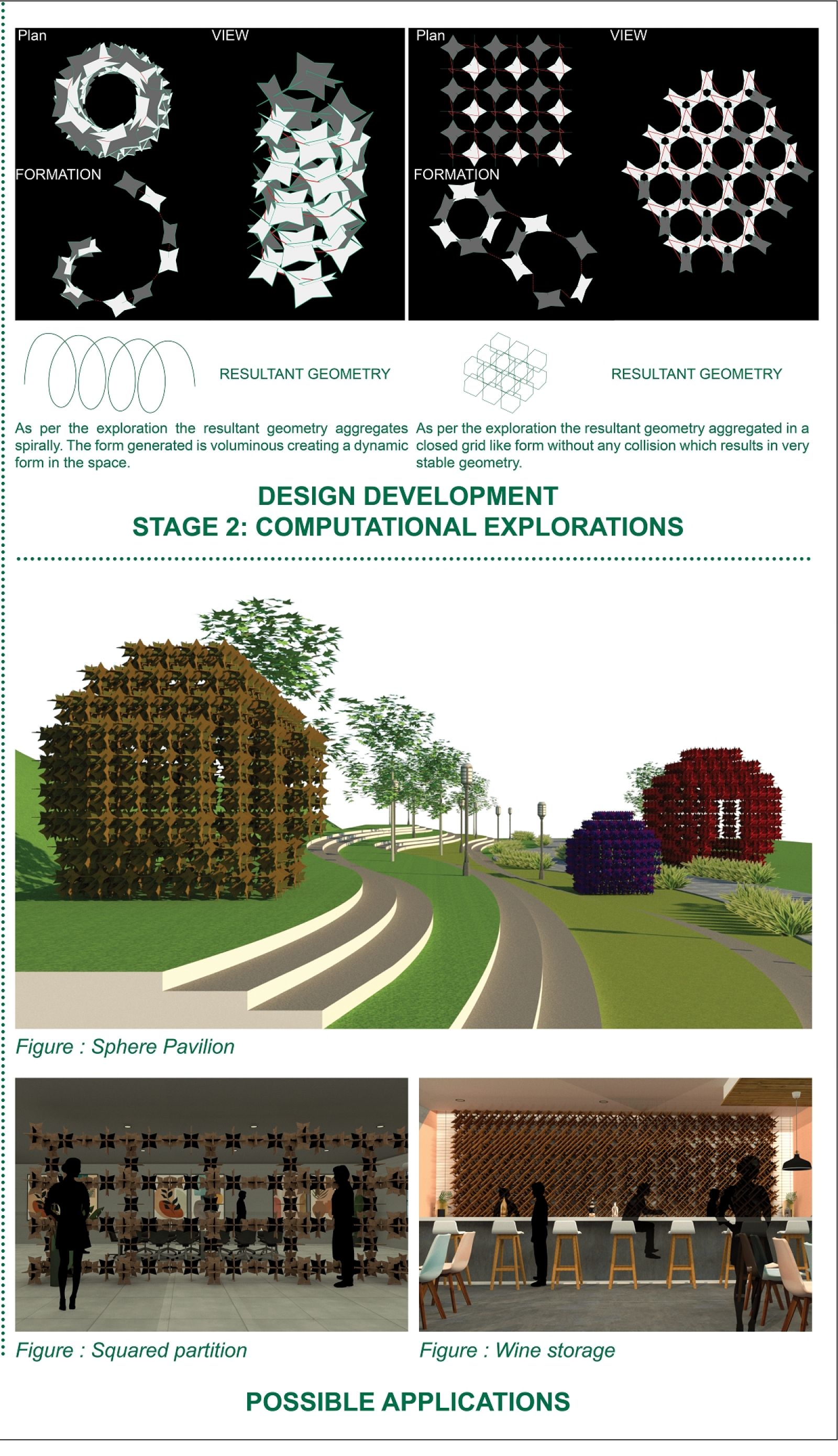

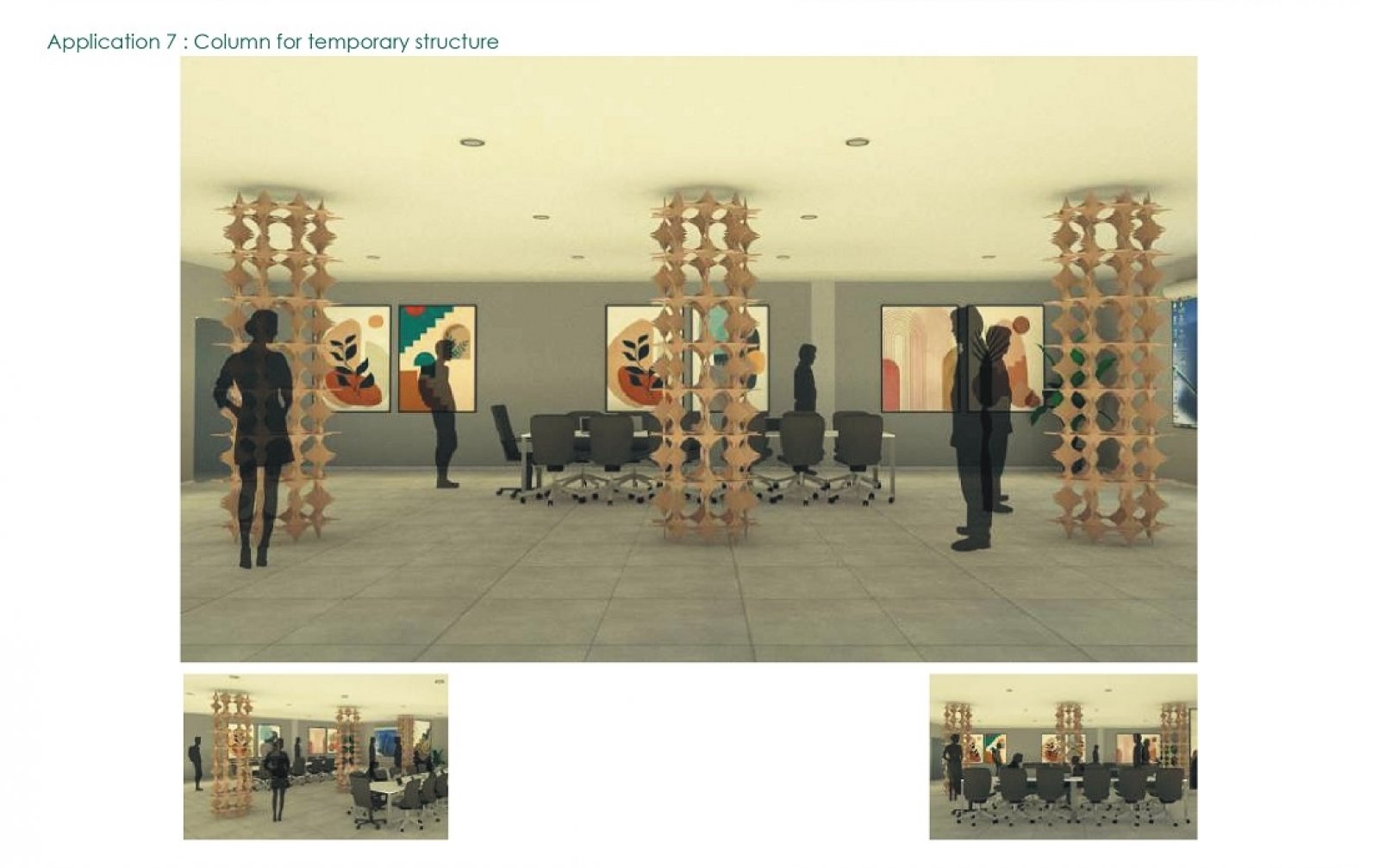

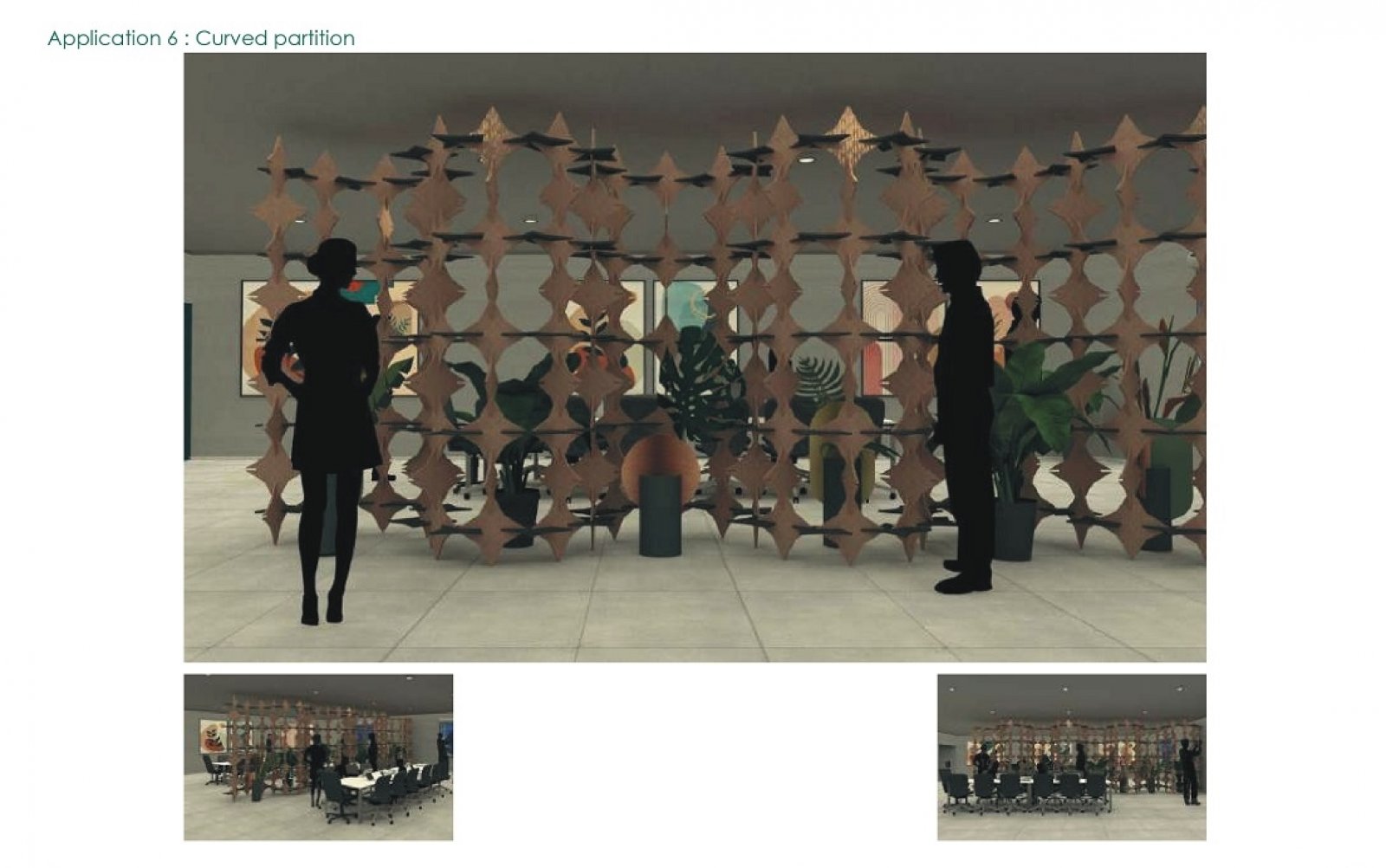

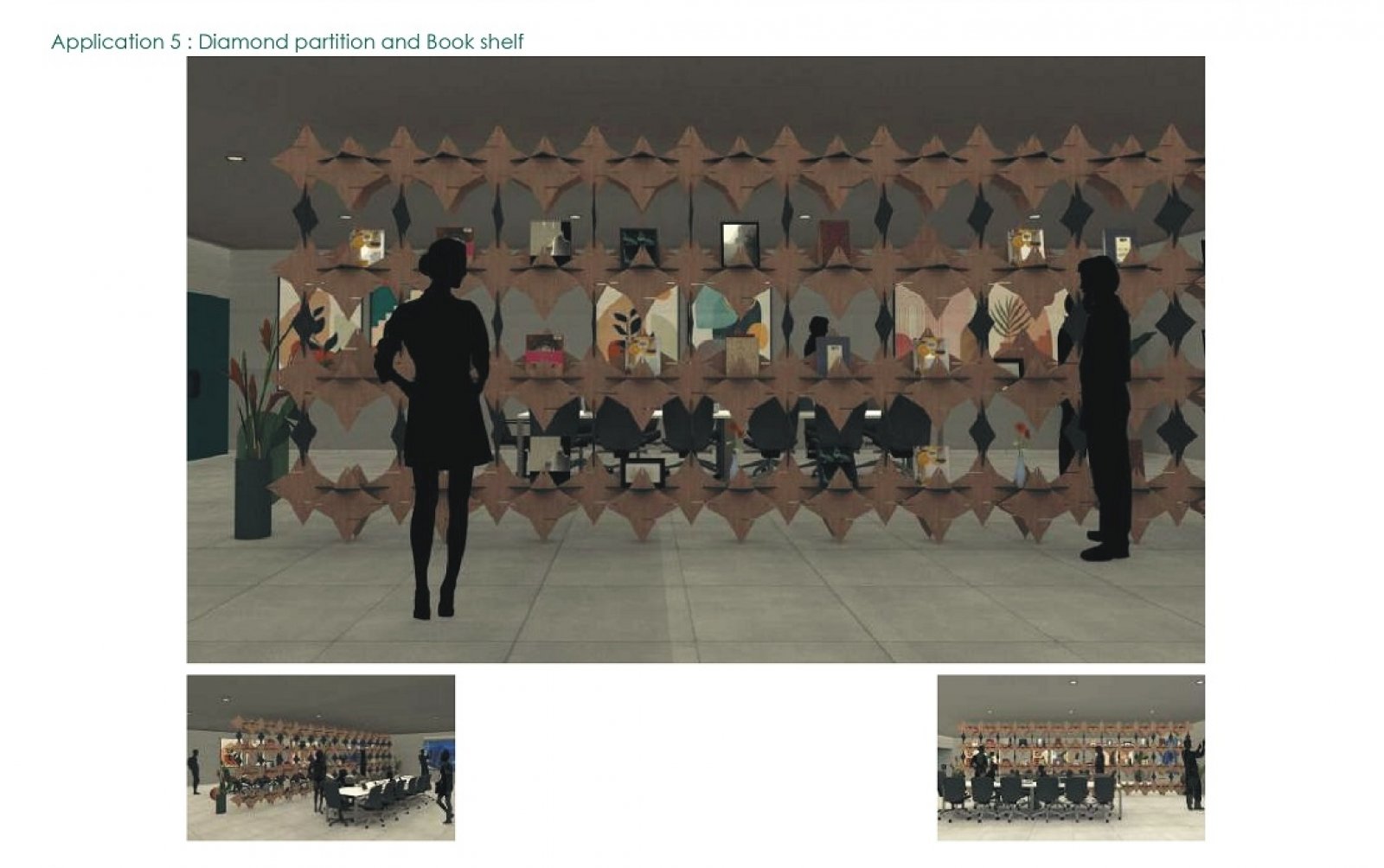

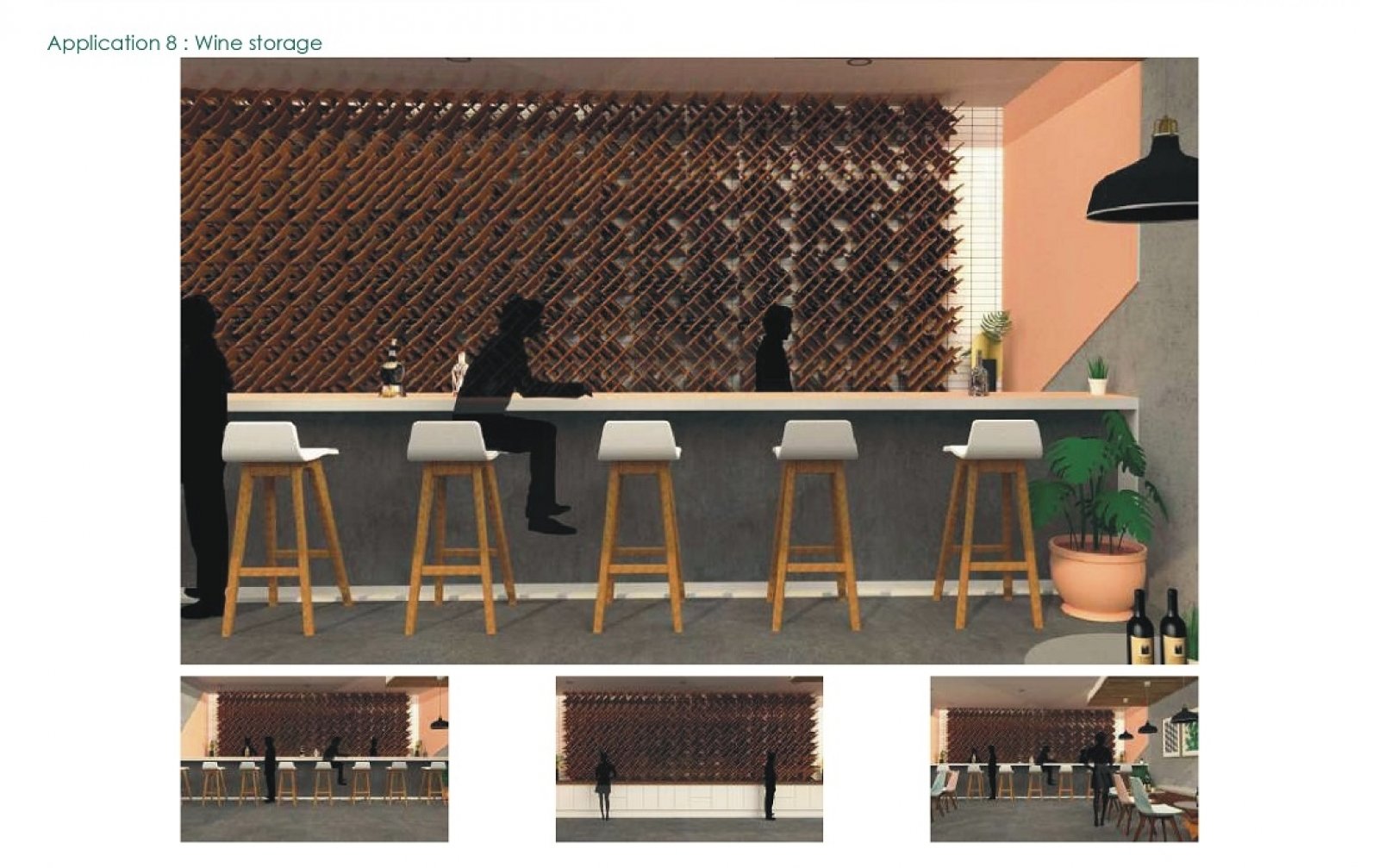

The assembly of the interlocking system is often used as a design solution to install or reinstall the same object elsewhere through the assembly and disassembly of the element. Using straight slits along the edges of the pieces, we can create very intricate three-dimensional forms without glue, screws, or other support means. Here, we explore a fabrication method and assembly system using two-dimensional units that can be interlocked and turned into three-dimensional modules—understanding the logic of 2D, 3D Interlocking puzzles which are often used on an architectural scale in Japan and many parts of the world. This research will explore and try to create different types of morphology that vary by using different rules of aggregations, location and number of grooves, and the unit's shape. The research examines the interlocking assembly units as an element in an interior environment by exploring different geometries. Addressing issues of space-saving, which can be flat packed, transported, and reassembled with minimal intervention, you can create a structural system that is strong and stable. This act of interlocking 90 degrees gives structural stability, which can use in furniture or a dwelling unit. The research is divided into three stages – 1. Understanding tessellations, 3D puzzles system, and interlocking applications in architecture. 2. Experimenting with different morphologies created by symmetric, semi symmetric, and asymmetric shapes. 3. Testing structural stability and different evaluation parameters and applying them to interiors.