Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

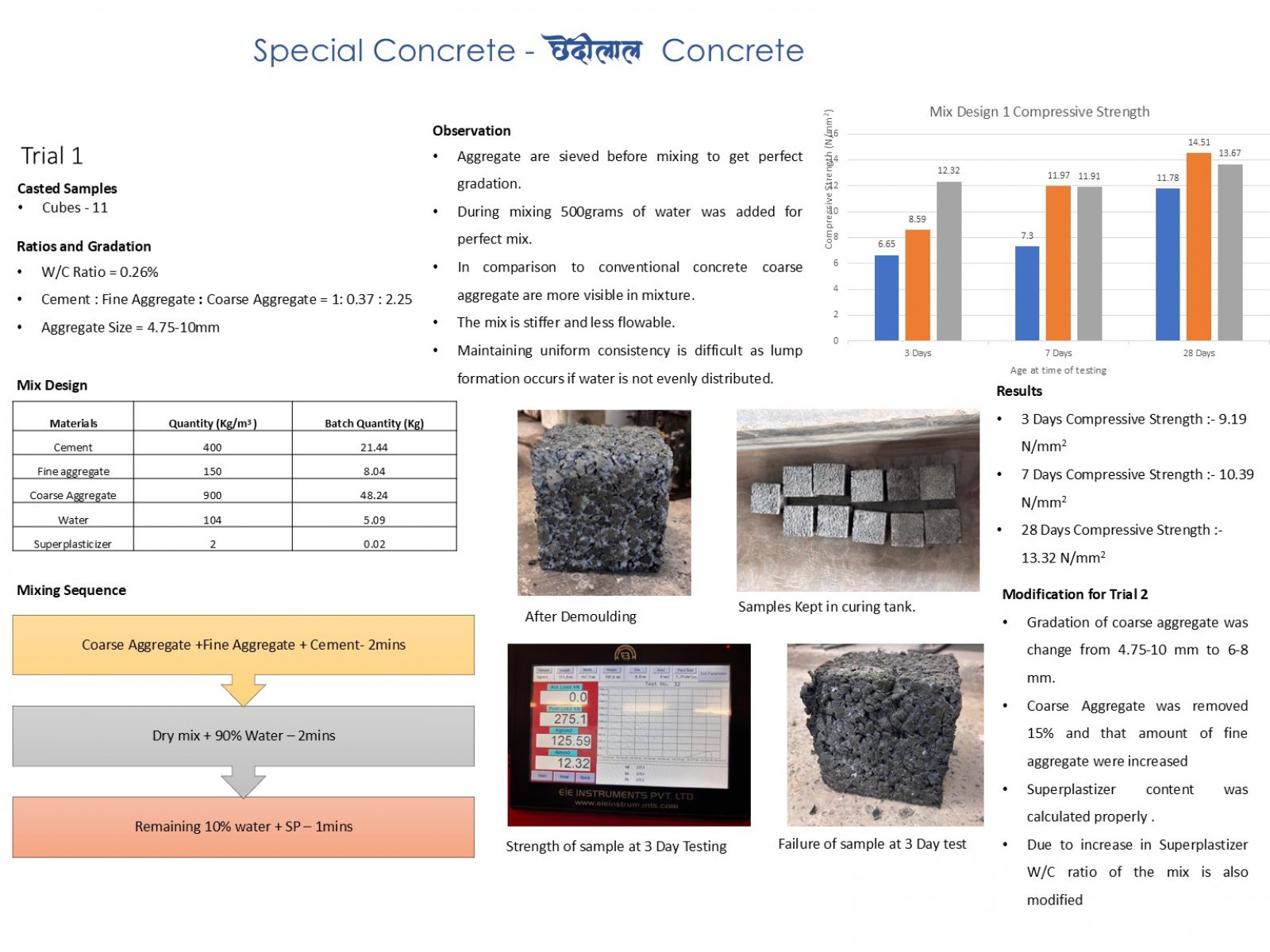

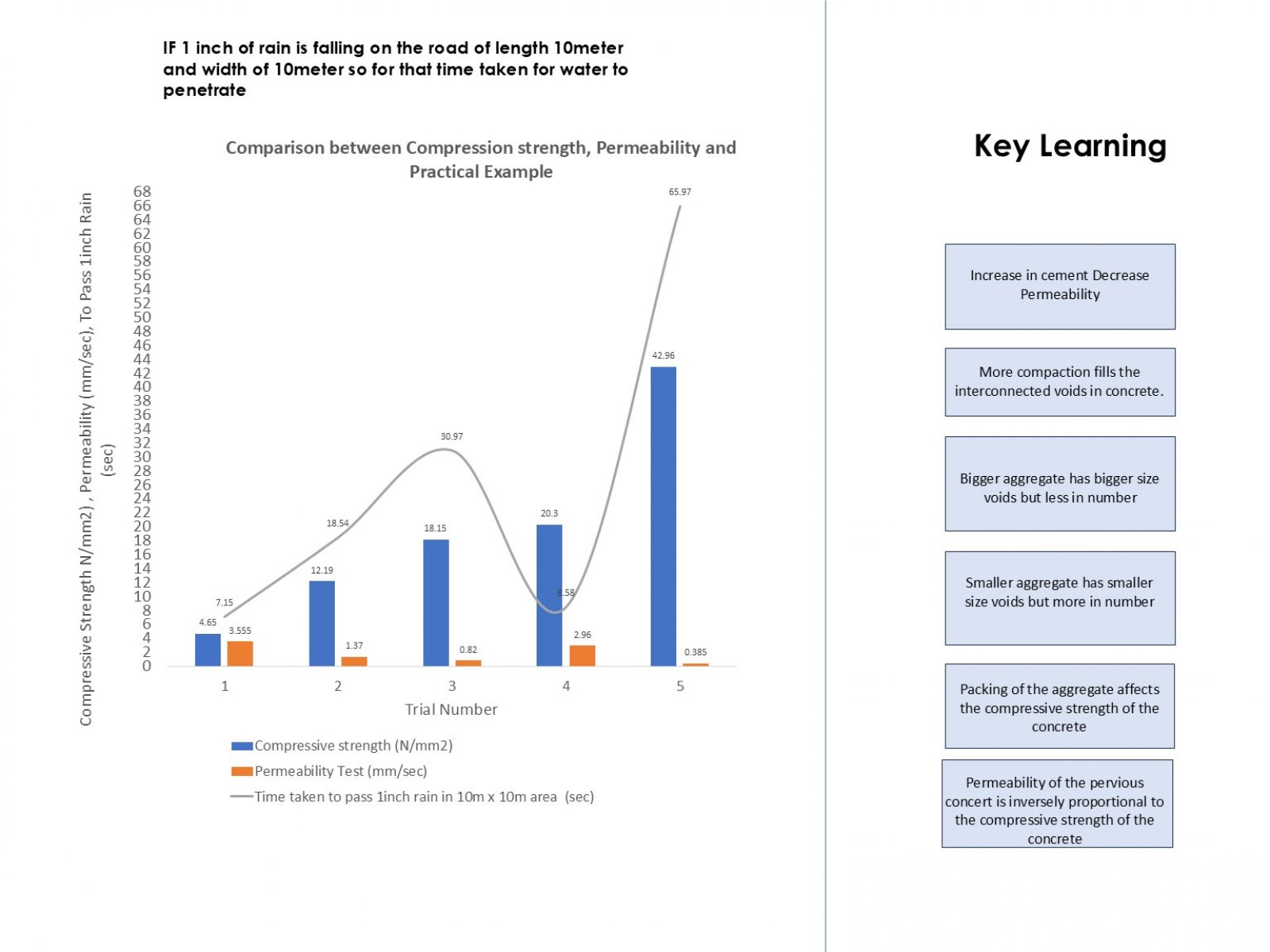

Pervious concrete is a special type of concrete that allows water to pass through it due to its interconnected pores. Unlike traditional concrete, it contains little to no fine aggregate, creating a porous structure that facilitates water infiltration. Impervious surfaces like conventional concrete increase surface runoff, leading to issues such as erosion, flooding, and reduced groundwater recharge. Pervious concrete addresses these challenges by offering high permeability while maintaining adequate strength. This eco-friendly material supports water management, reduces runoff, and promotes sustainability, making it ideal for modern infrastructure.