Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

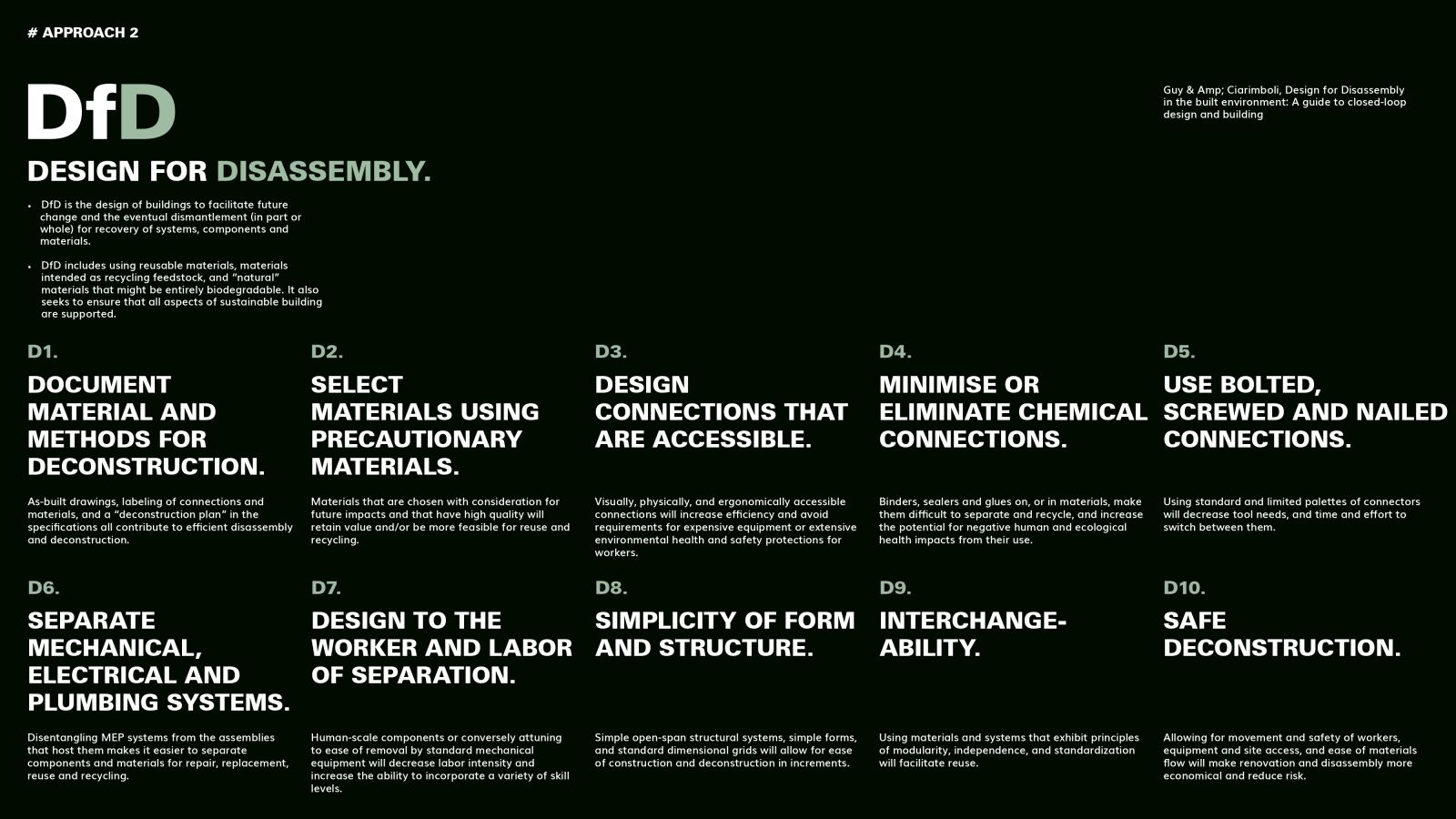

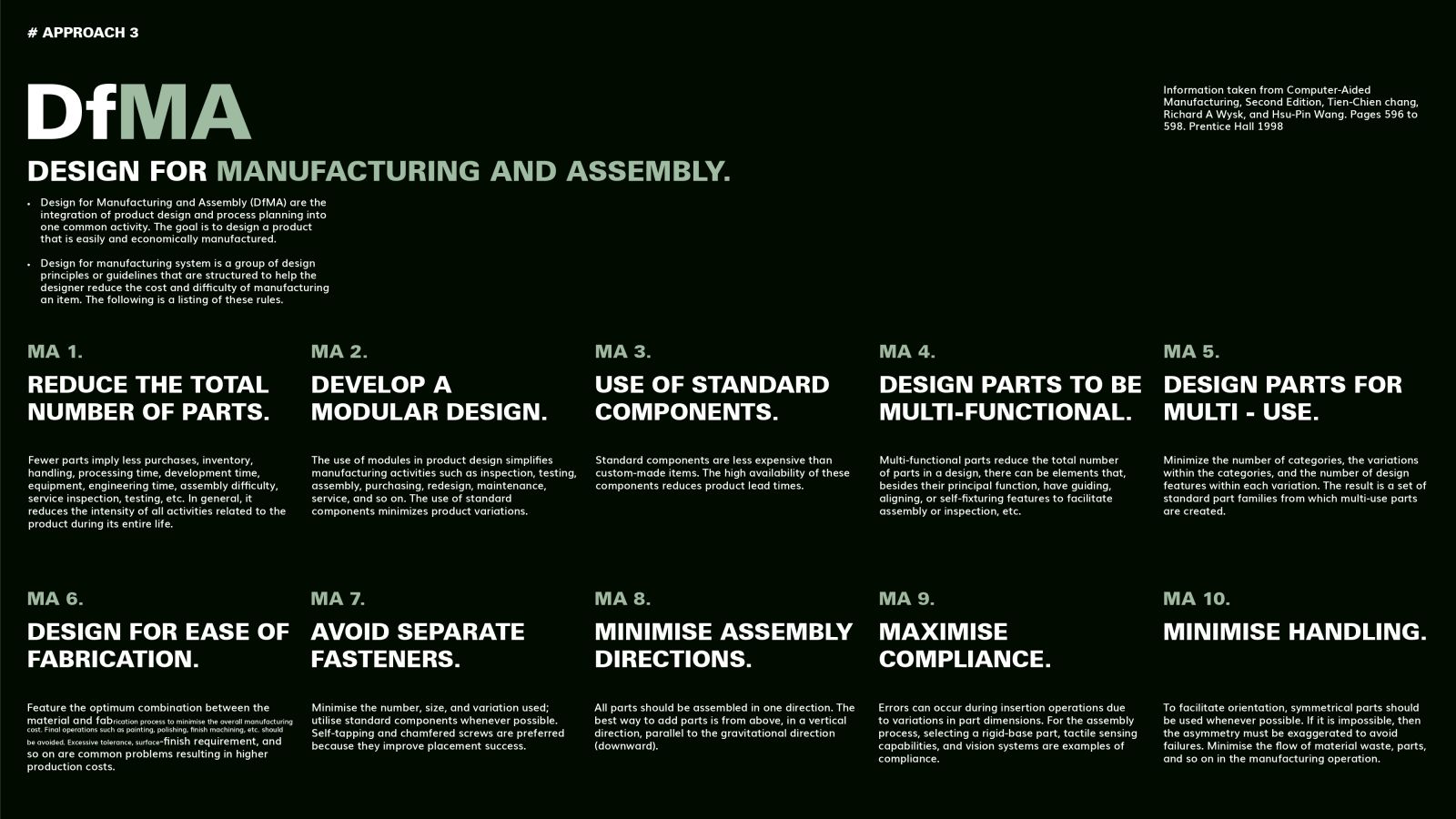

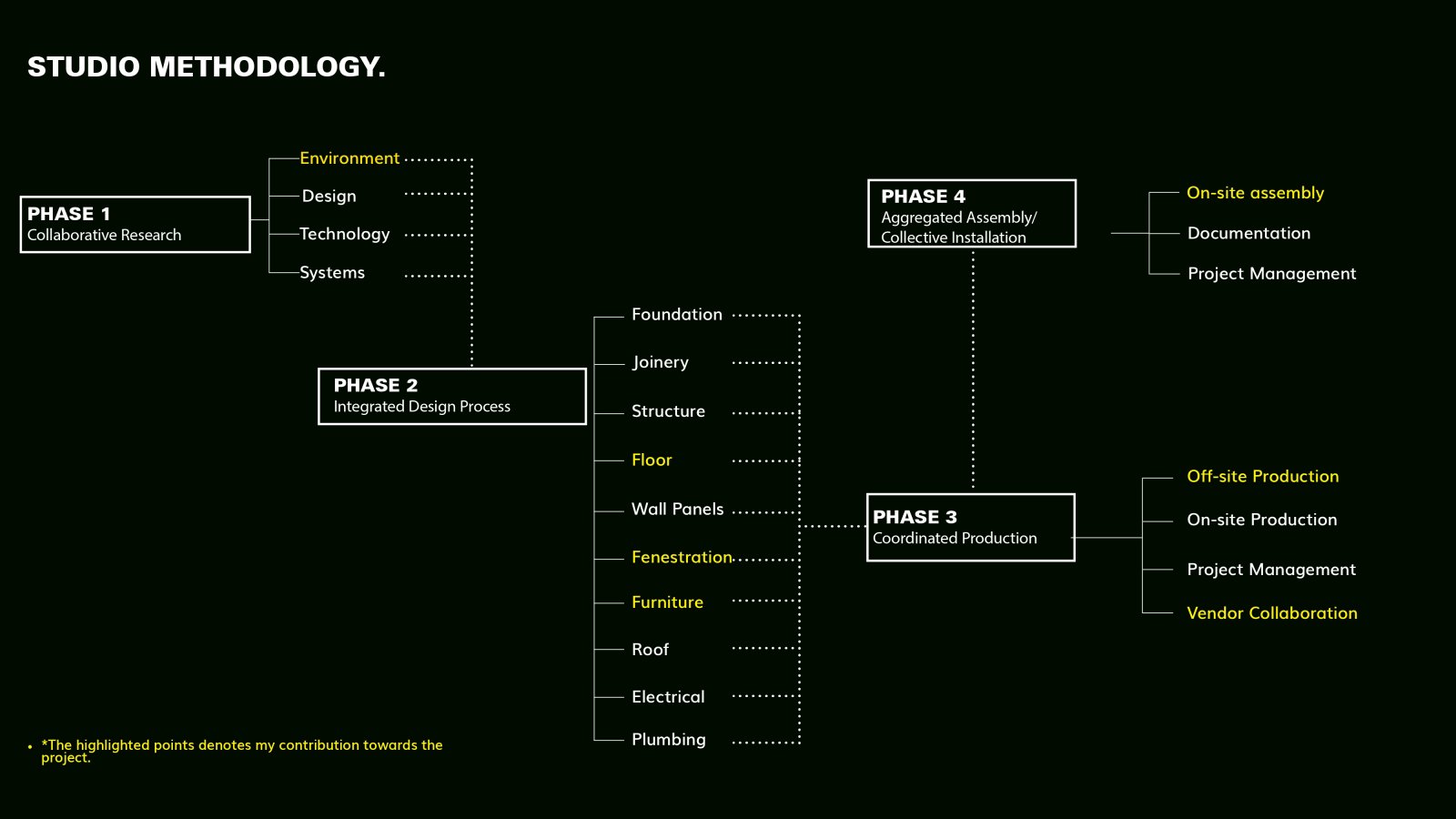

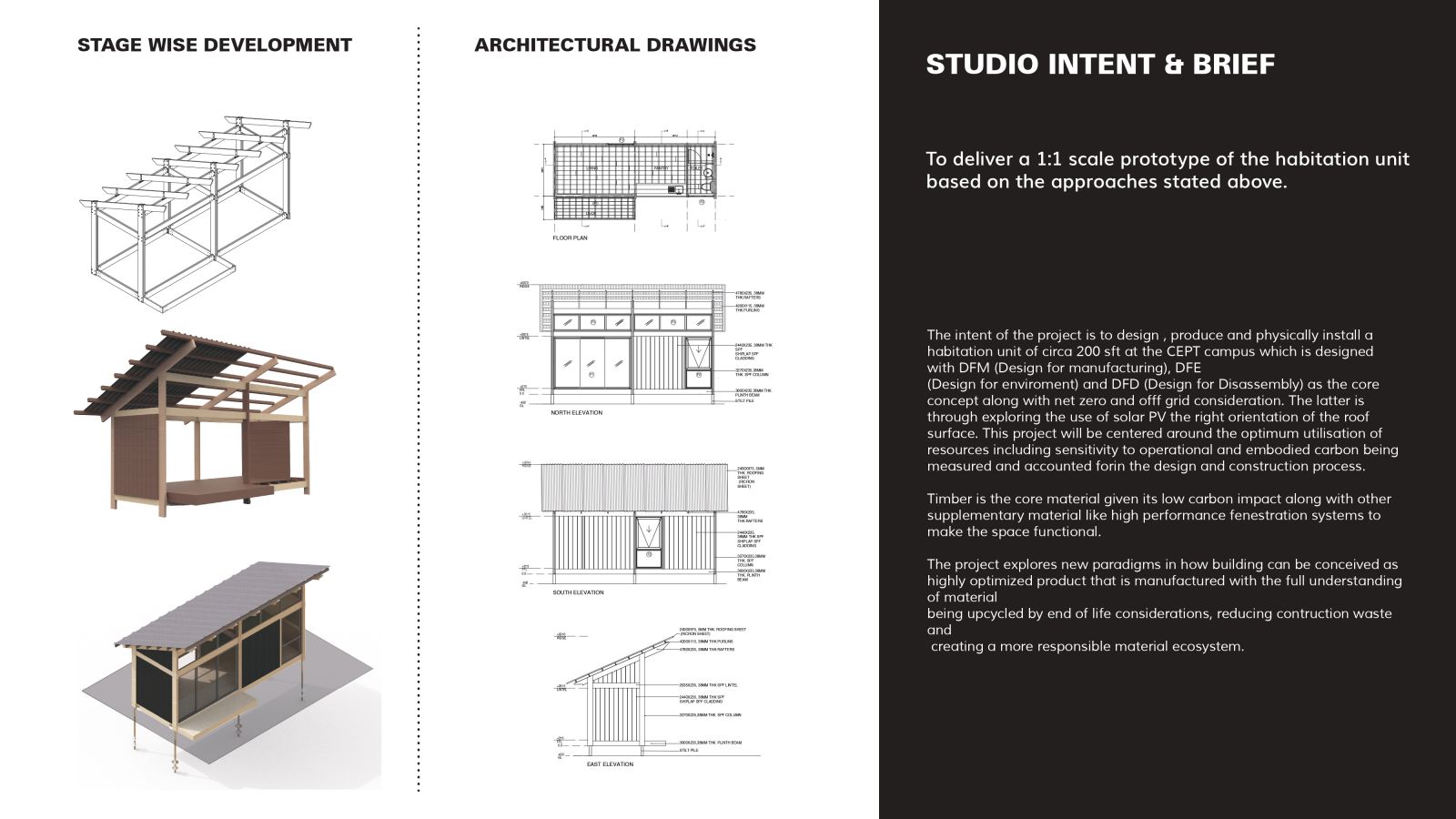

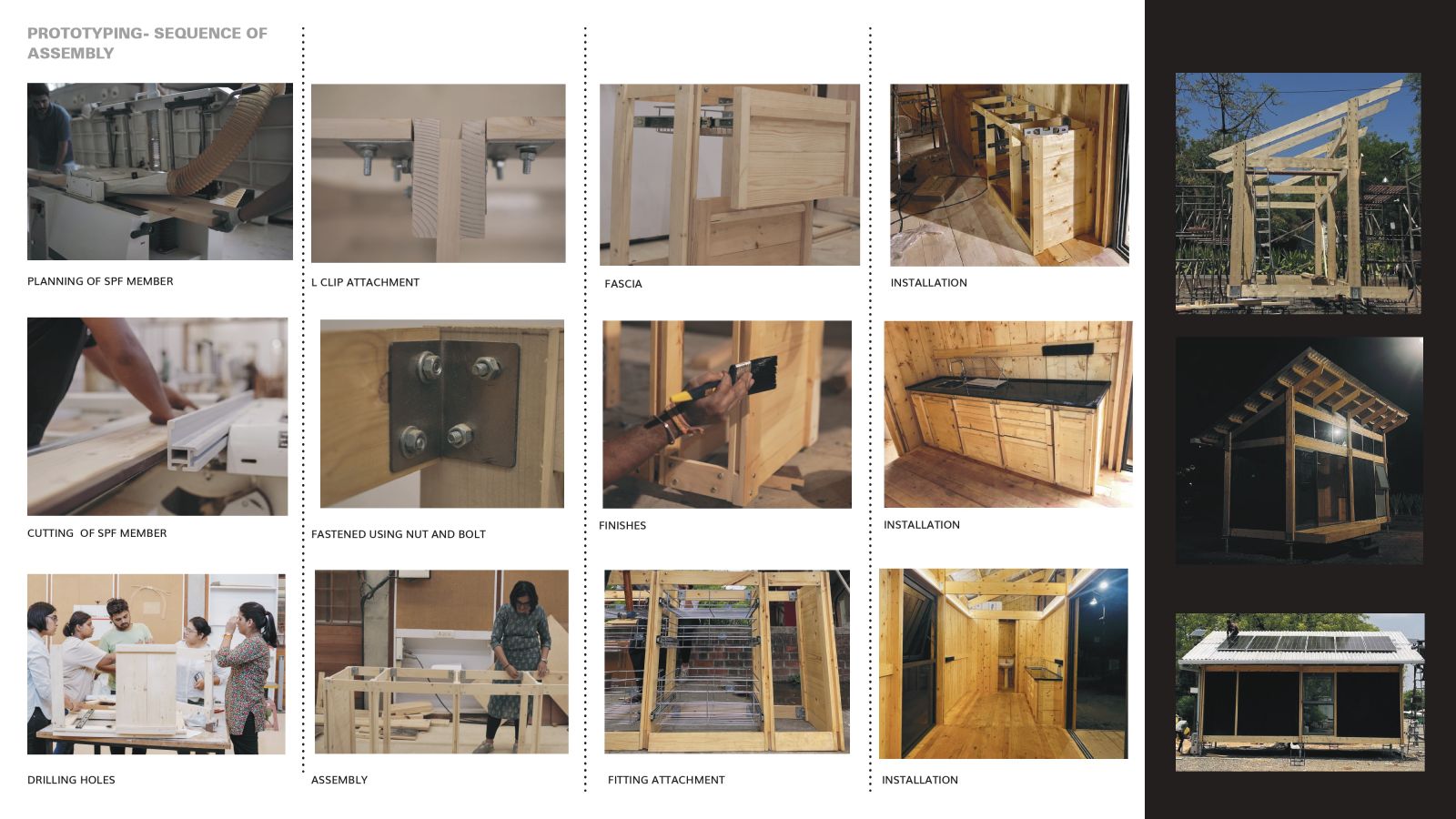

To deliver a 1:1 scale prototype of the habitation unit based on the approaches stated above.The intent of the project is to design, produce and physically install a habitation unit of circa 200 sft at the CEPT campus which is designed with DFM (Design for manufacturing), DFE

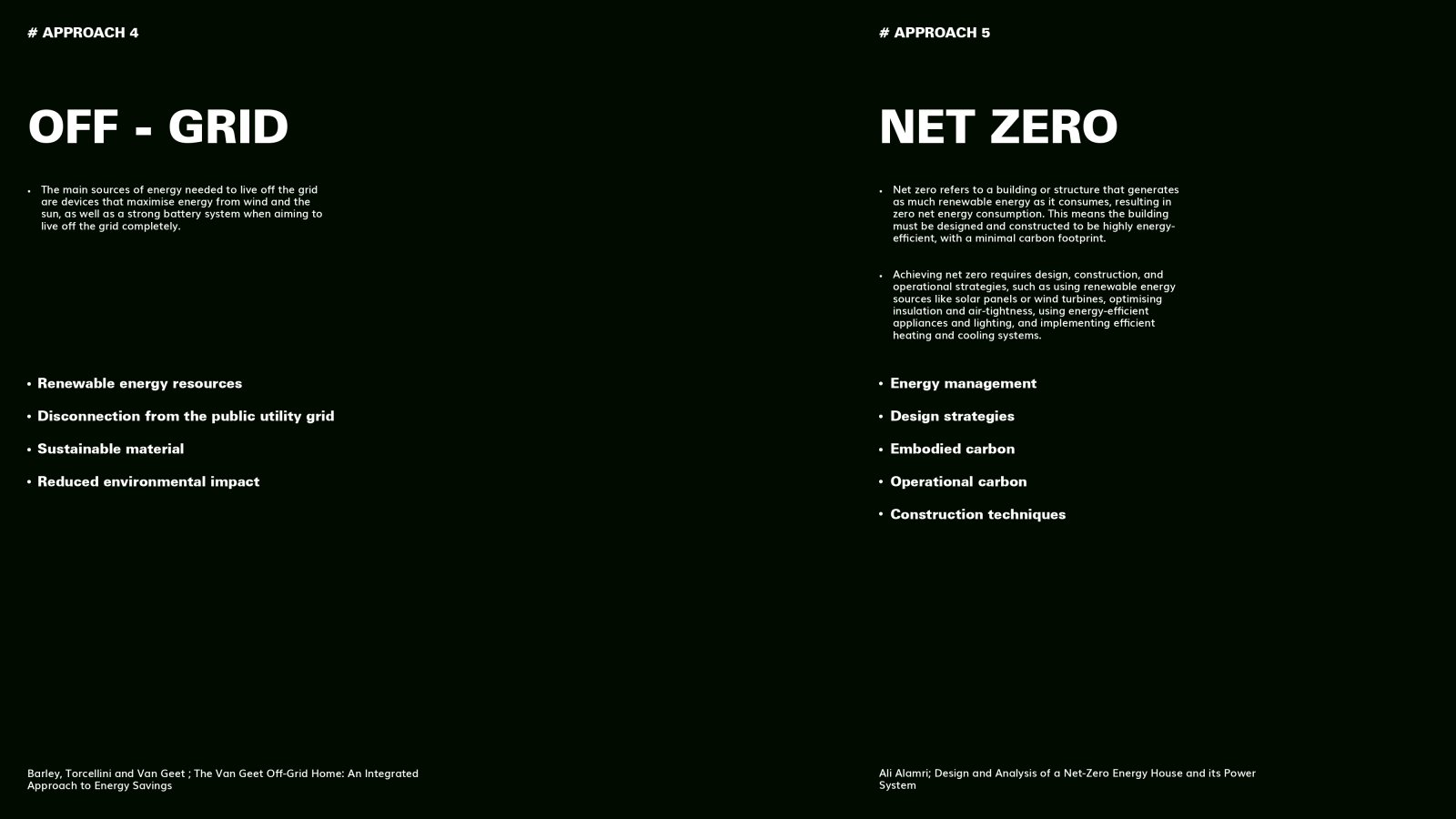

(Design for the environment) and DFD (Design for Disassembly) as the core concept along with net zero and off-grid consideration. The latter is through exploring the use of solar PV and the right orientation of the roof

surface. This project will be centered around the optimum utilization of resources including sensitivity to operational and embodied carbon being measured and accounted for in the design and construction process.

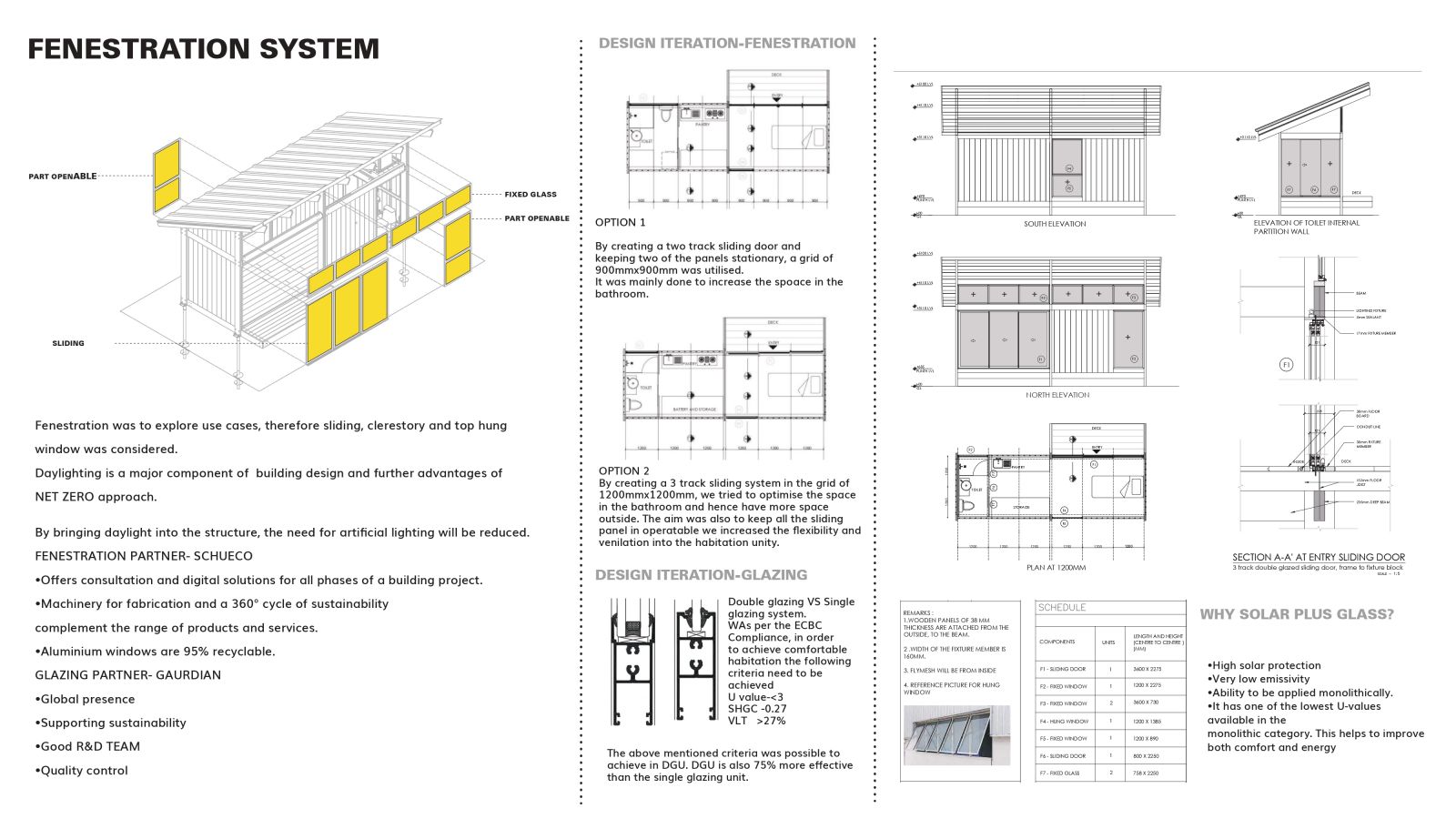

Timber is the core material given its low carbon impact along with other

supplementary materials like high-performance fenestration systems to make the space functional.

The project explores new paradigms in how the building can be conceived as a highly optimized product that is manufactured with the full understanding of the material

being upcycled by end-of-life considerations, reducing construction waste and

creating a more responsible material ecosystem.

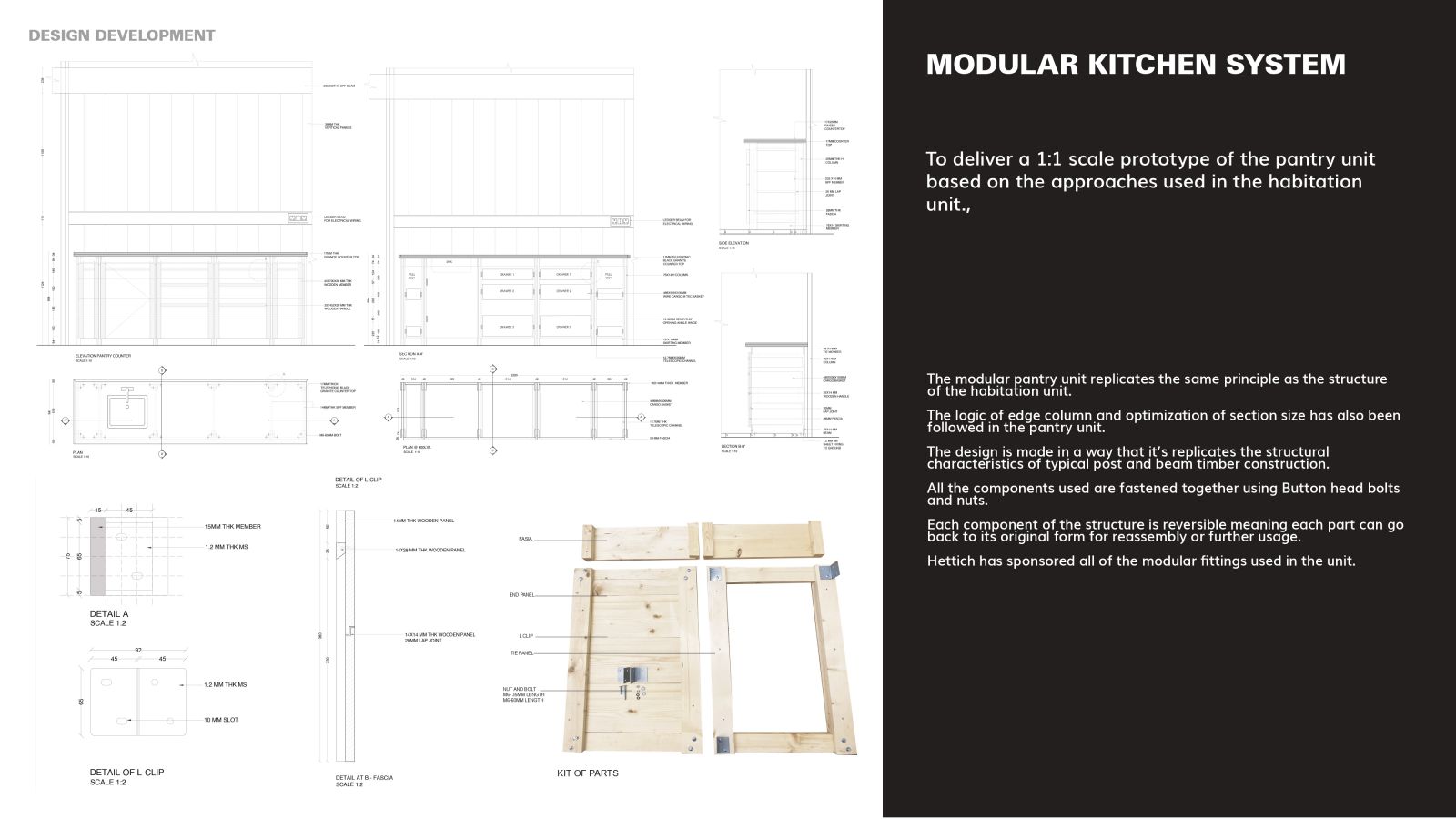

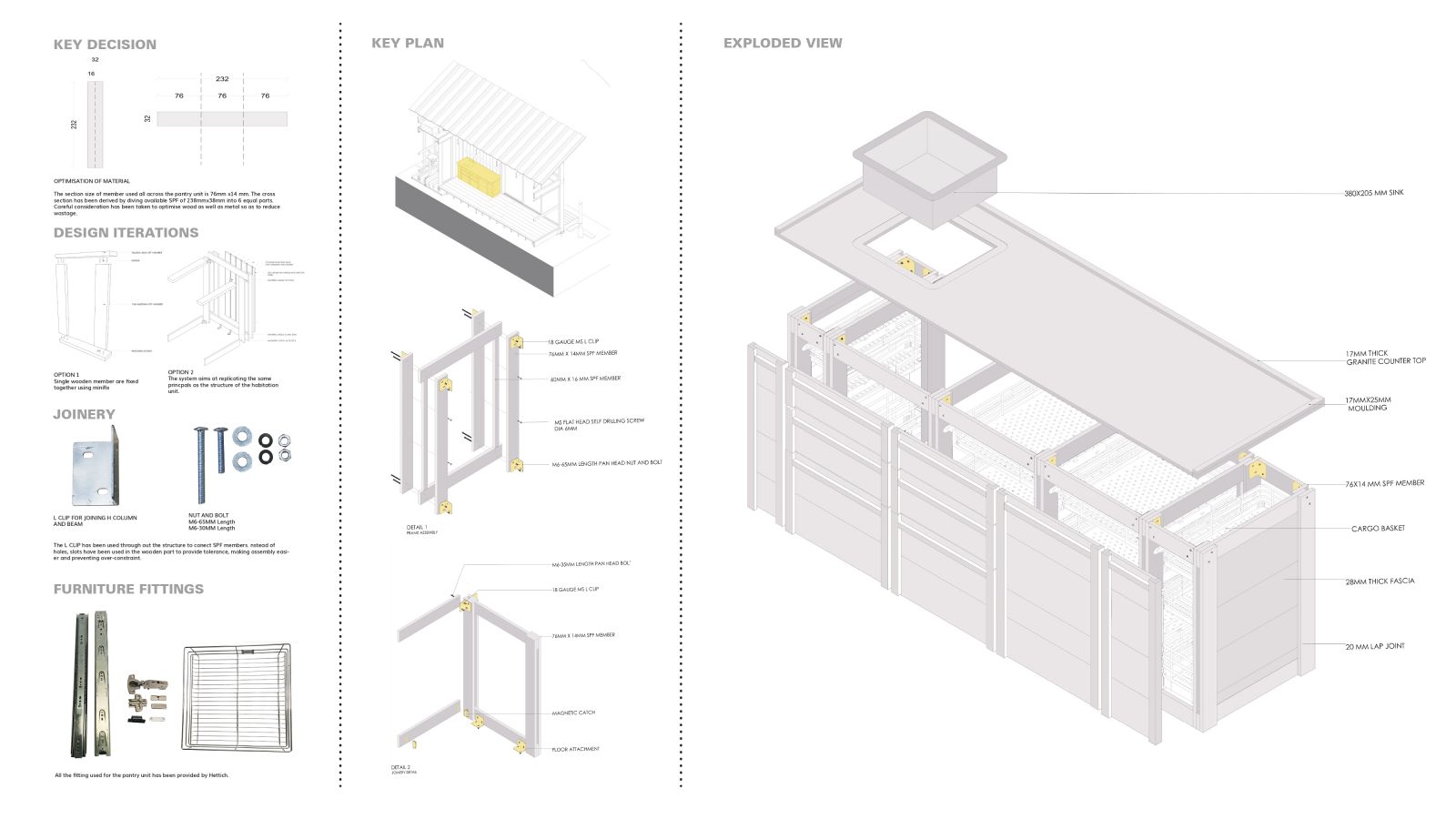

The modular pantry unit replicates the same principle as the structure of the habitation unit.

The logic of edge column and optimization of section size has also been followed in the pantry unit.

The design is made in a way that it’s replicates the structural characteristics of typical post and beam timber construction.

All the components used are fastened together using Button head bolts and nuts.

Each component of the structure is reversible meaning each part can go back to its original form for reassembly or further usage.