Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

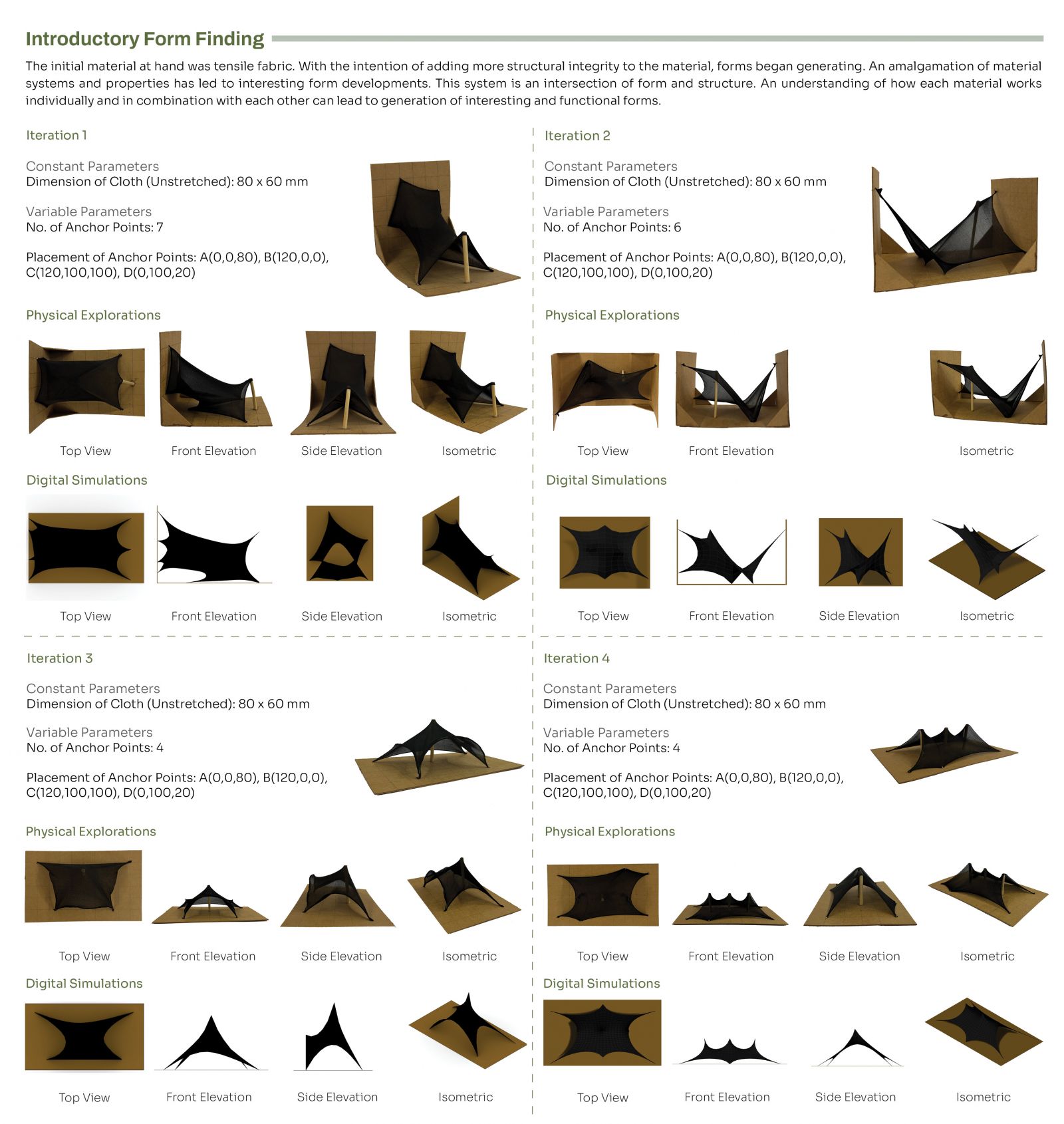

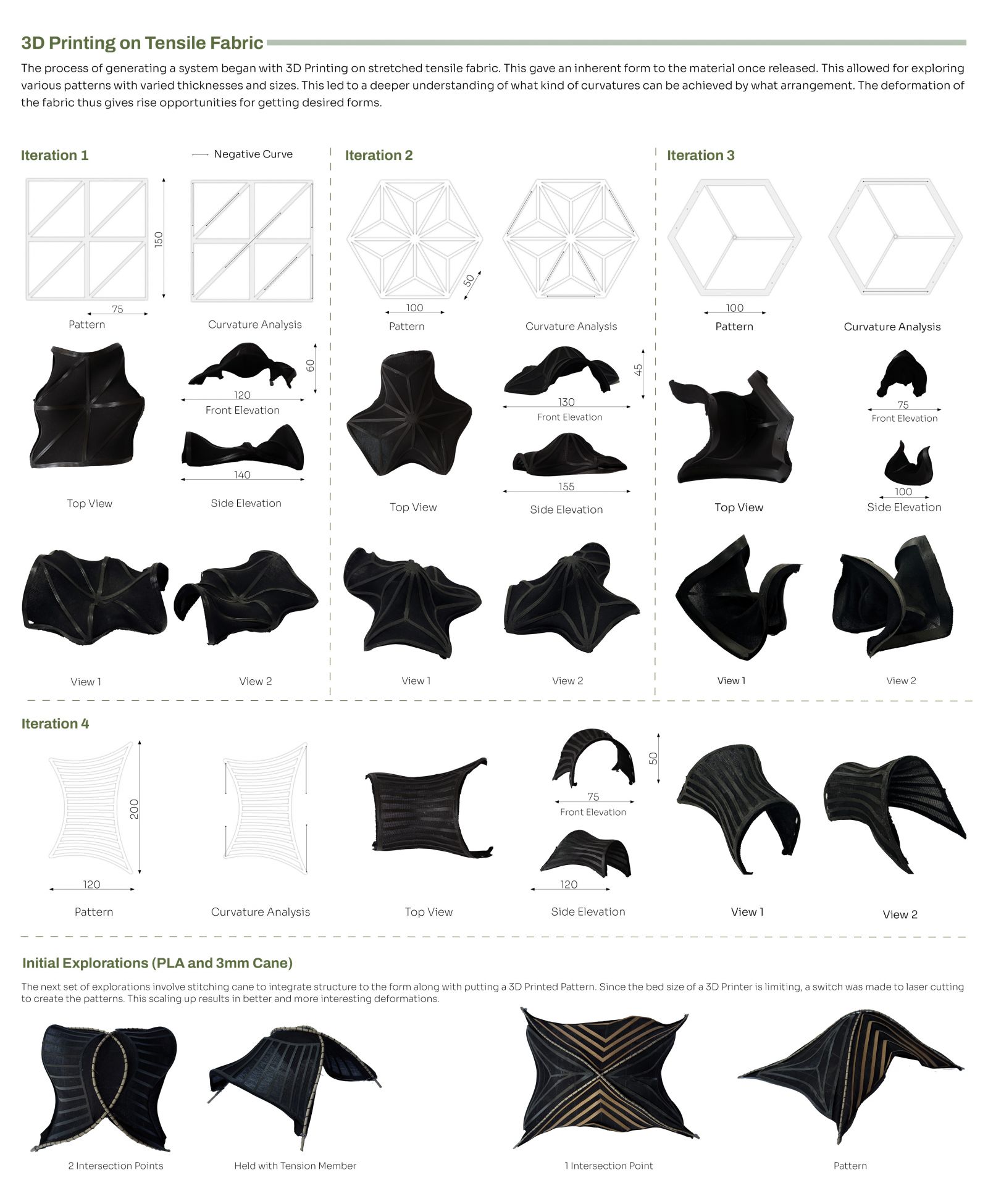

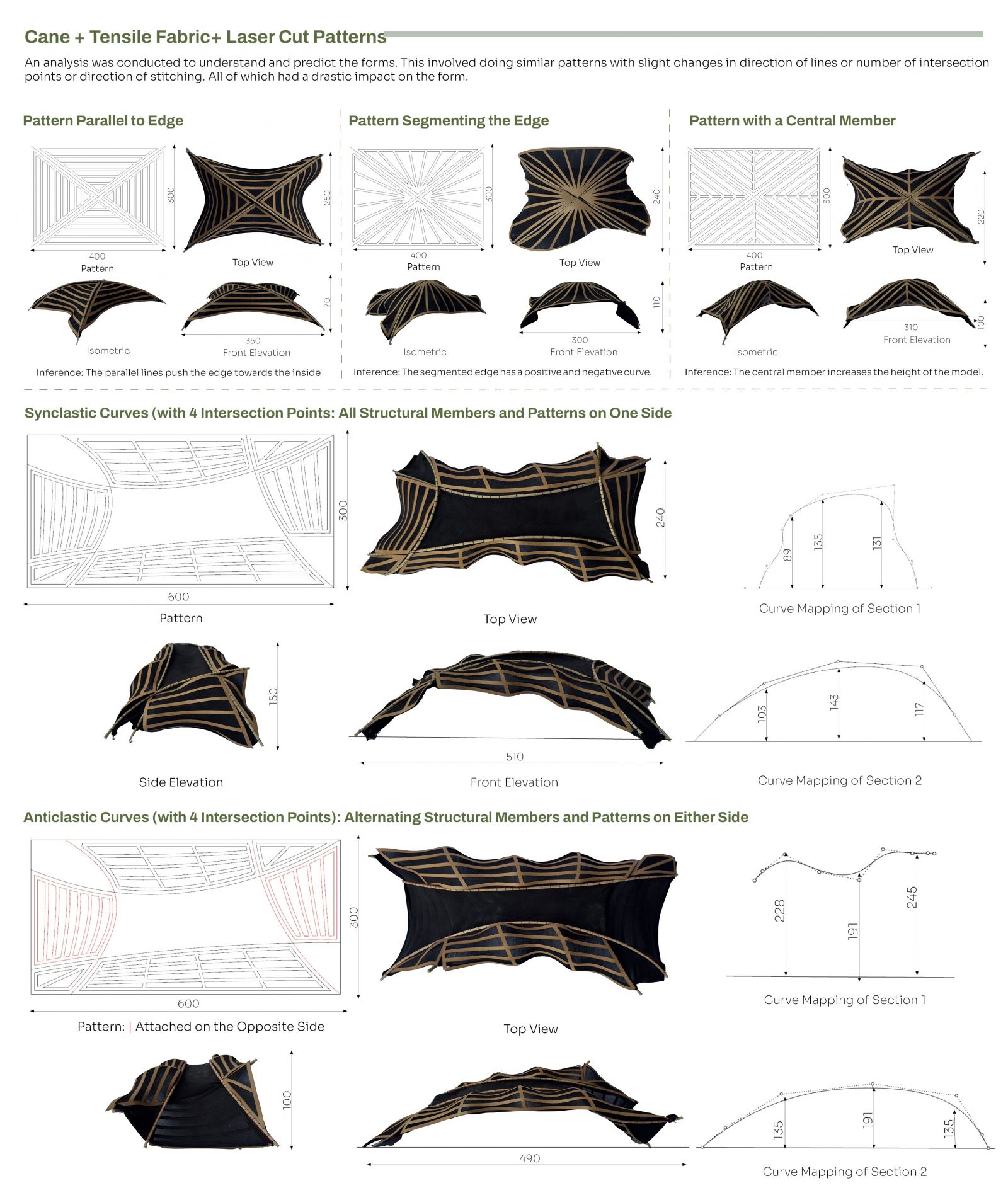

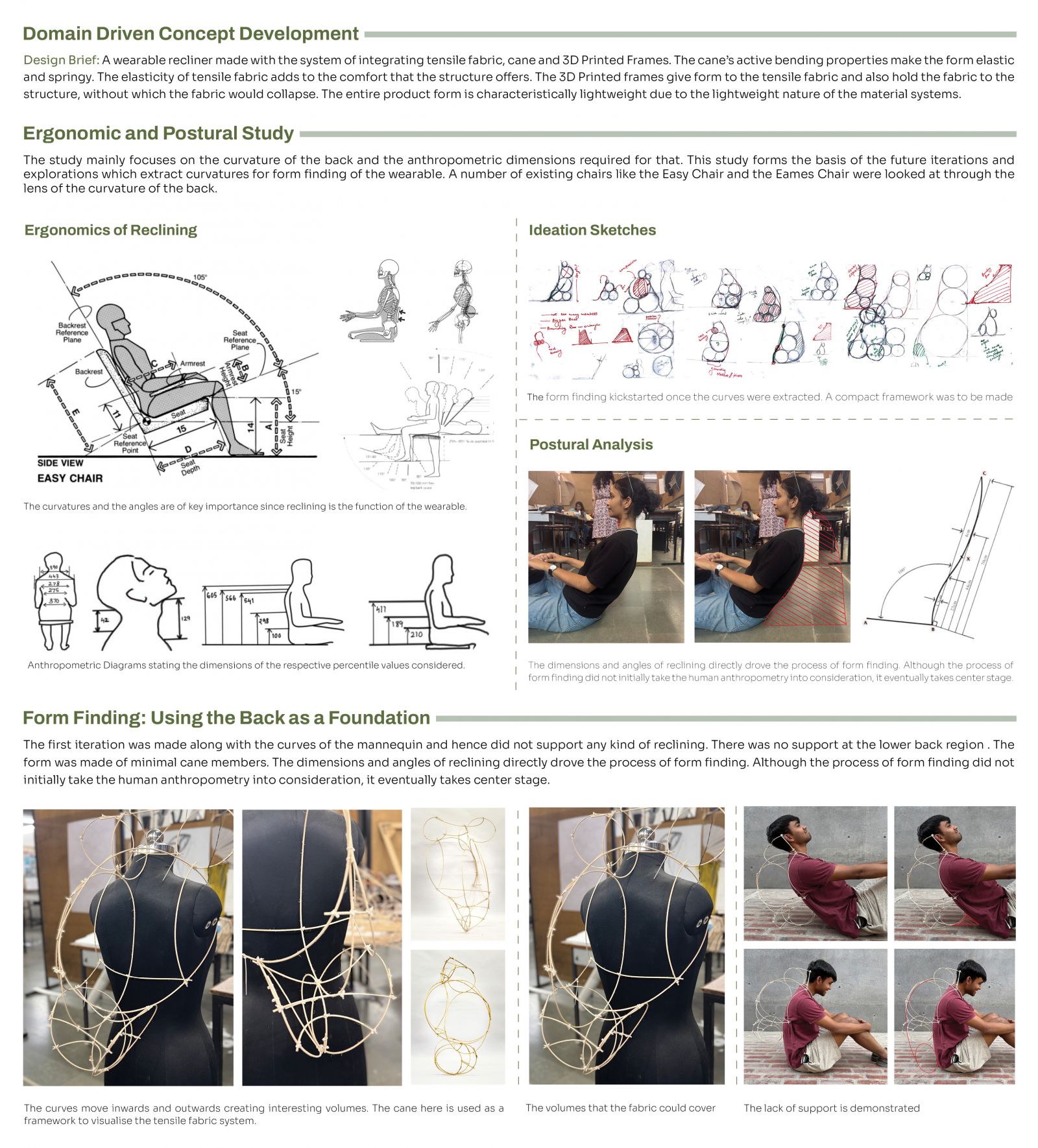

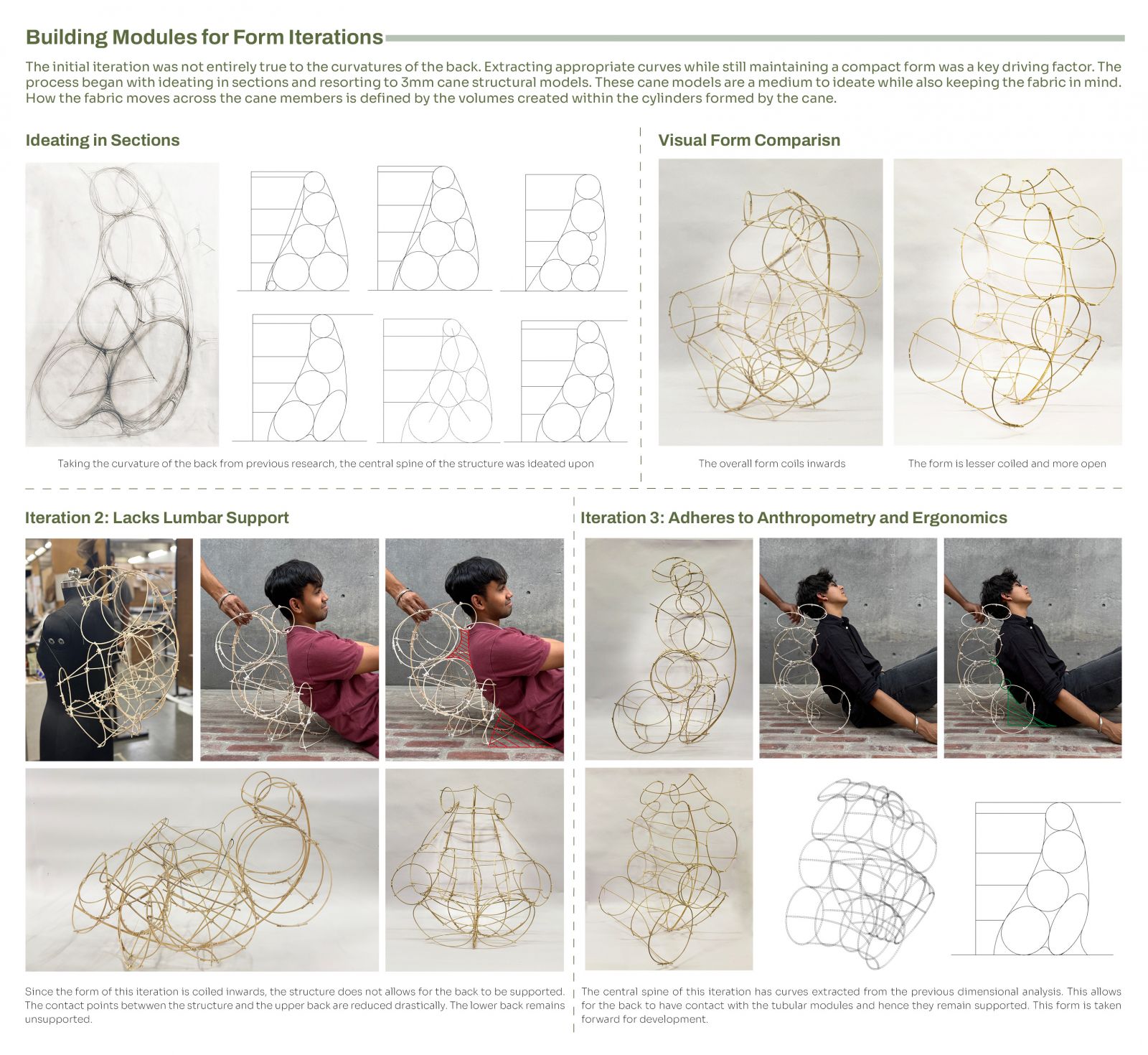

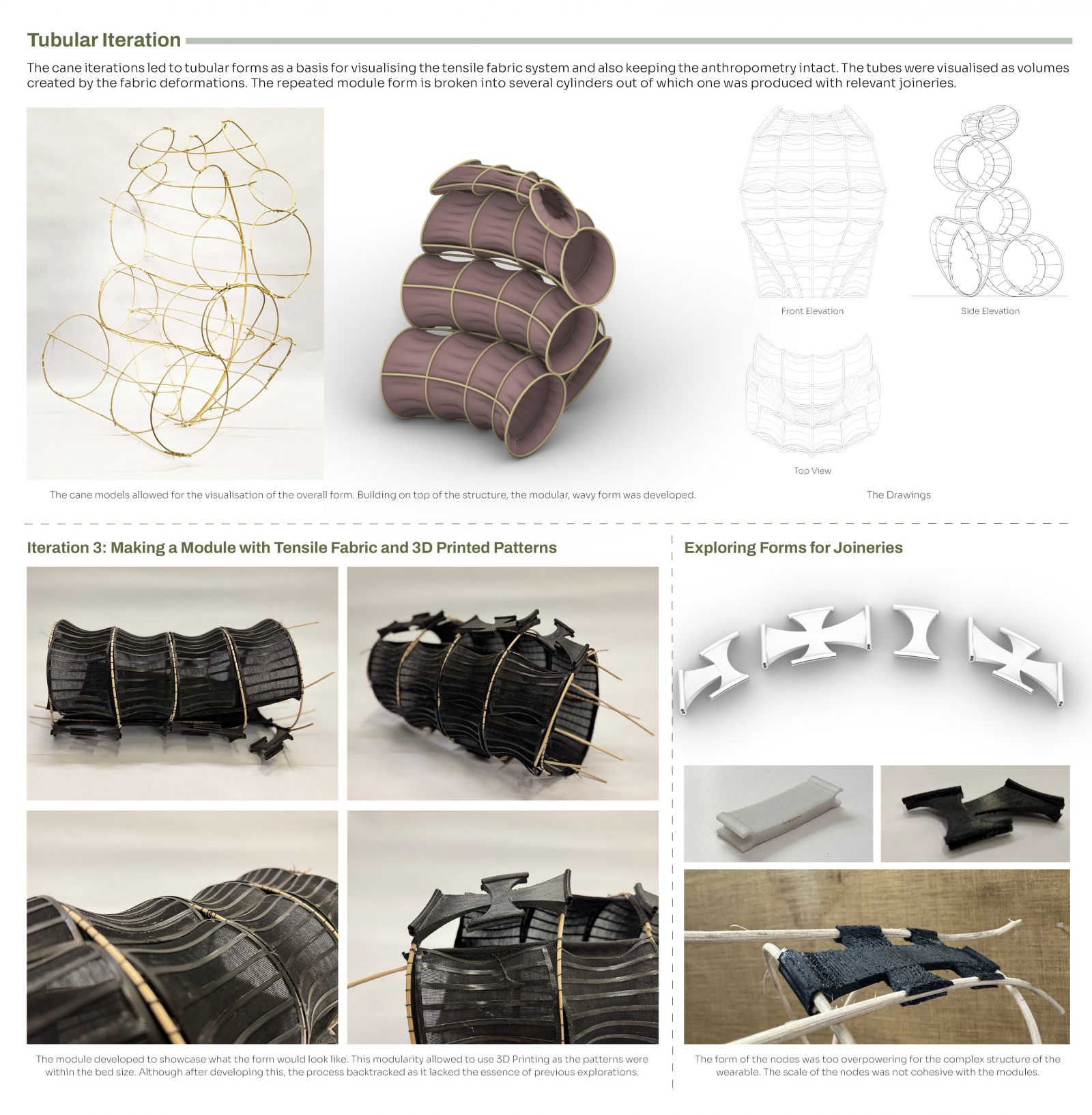

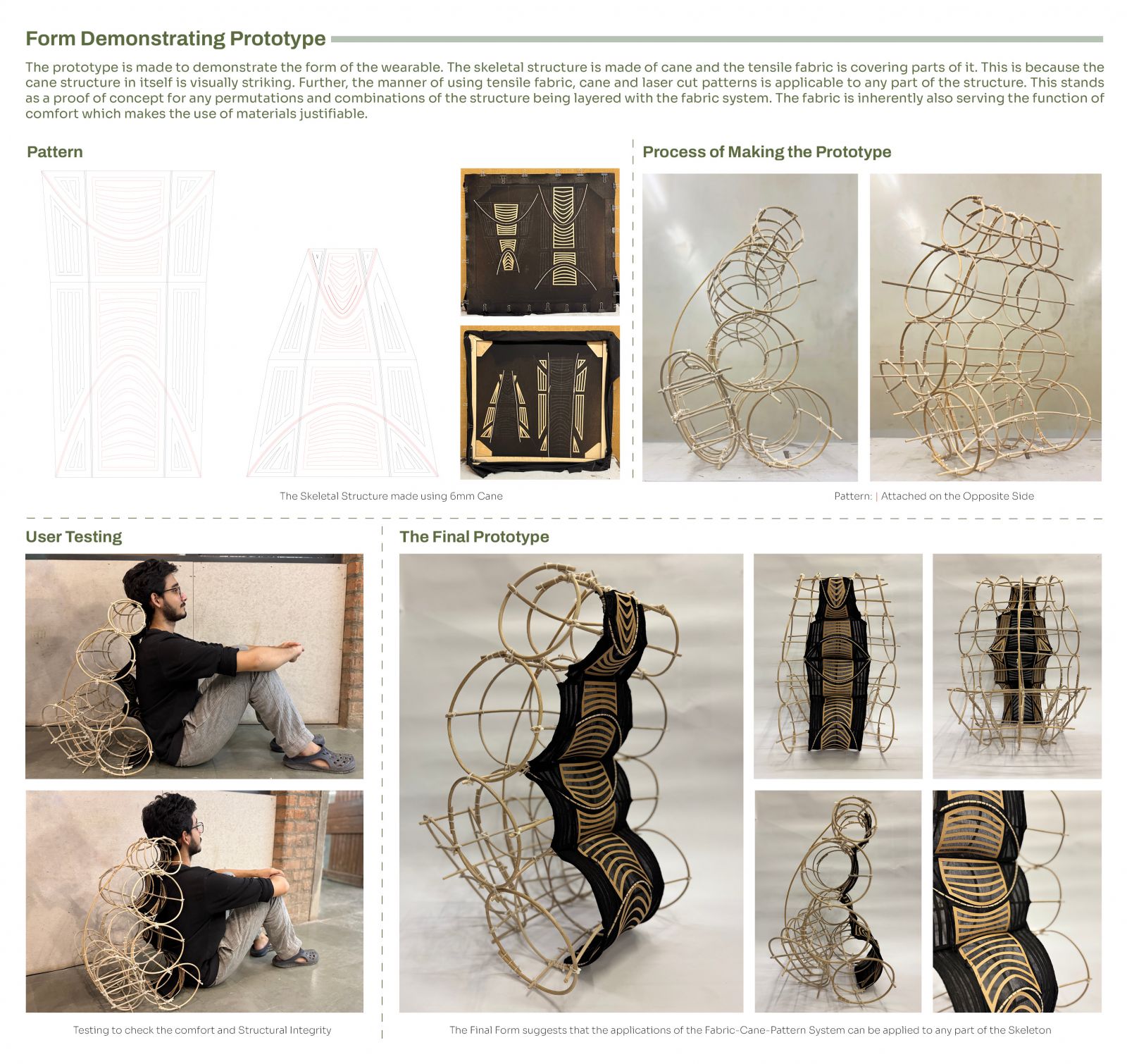

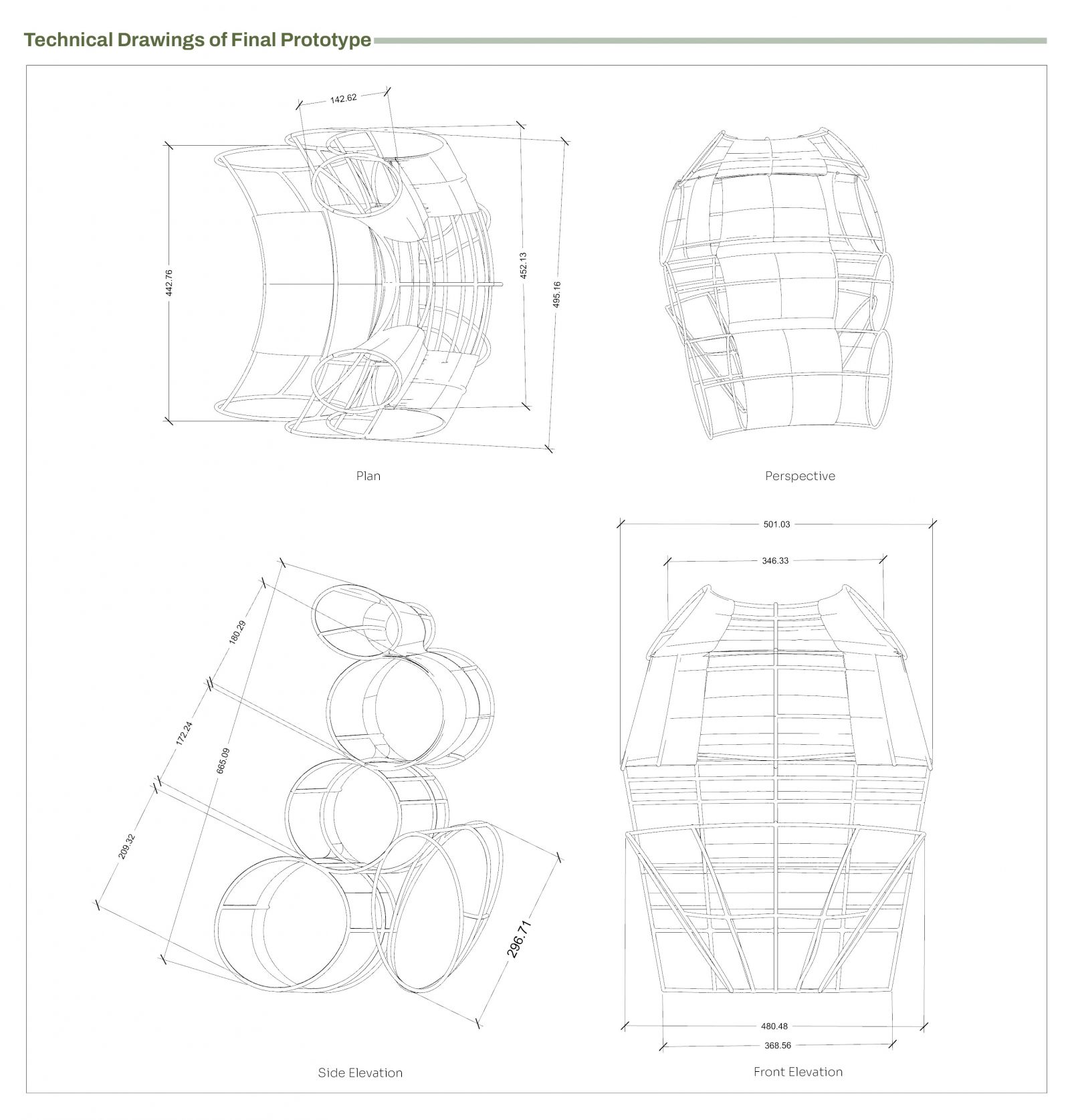

This project aimed to explore the interwoven qualities of how structure and form unite using tensile fabric, cane and fabrication techniques like 3D Printing or Laser Cutting. This led to the creation of dynamic forms which were then pushed further to achieve Double-Curved Forms and Surfaces. The active bending and structural integrity of cane, elasticity of tensile fabric and structural properties of 3D Printed Patterns, brought forth a demonstration of a Lightweight, Cushiony, Wearable Recliner. This project explored the Form Finding process through anthropometry and pattern generation.

View Additional Work