Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

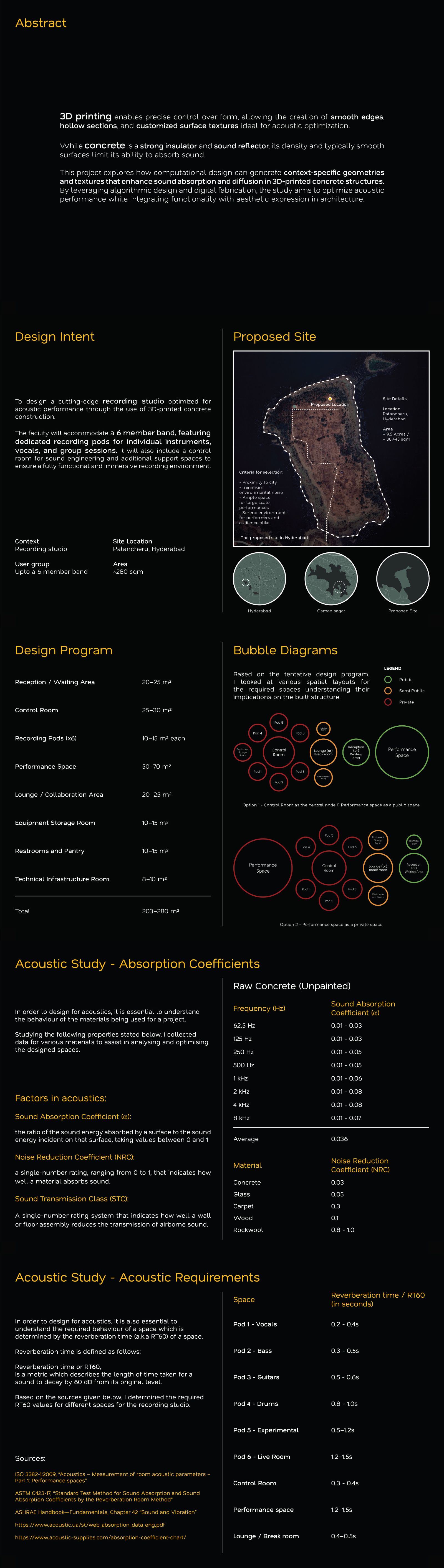

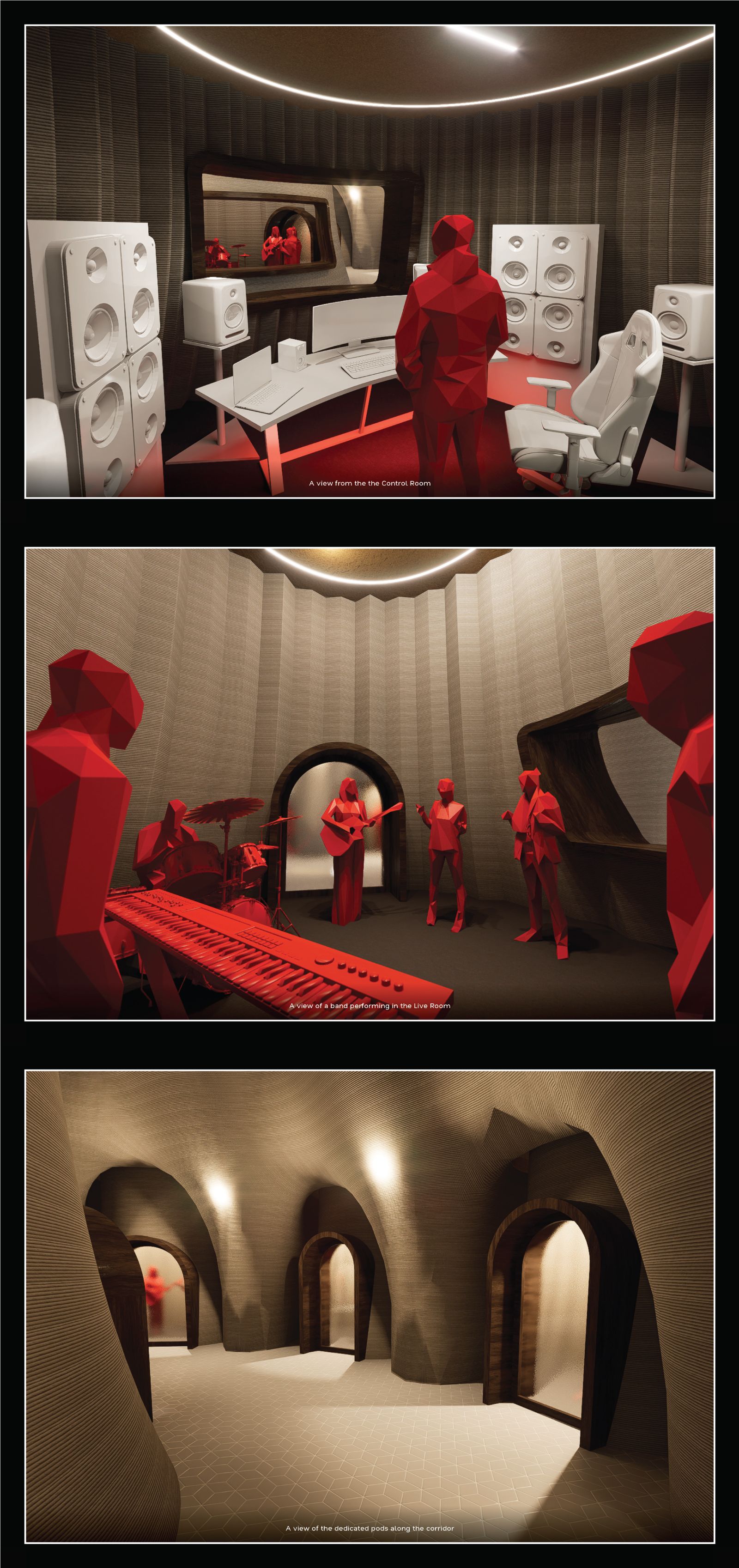

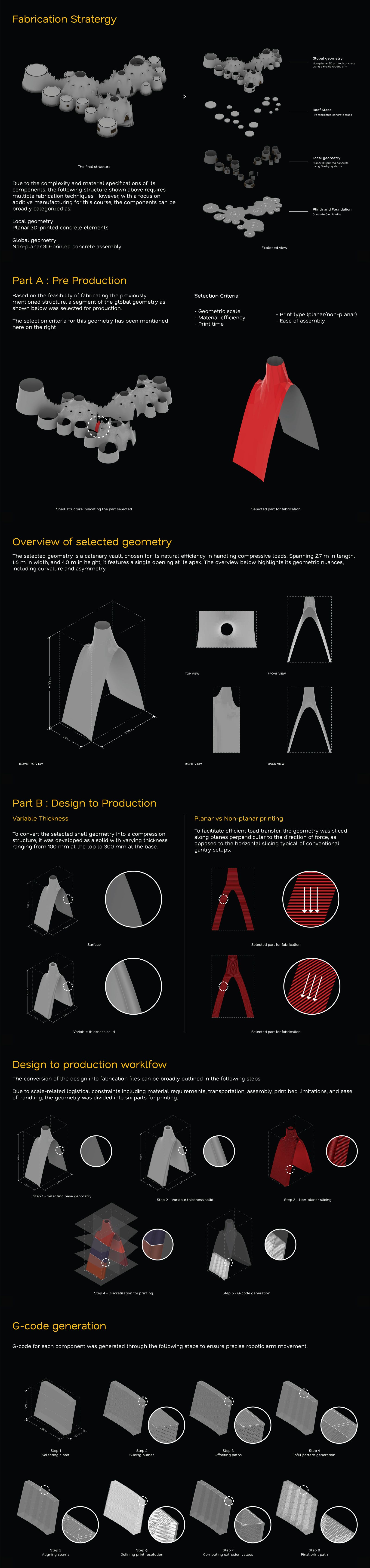

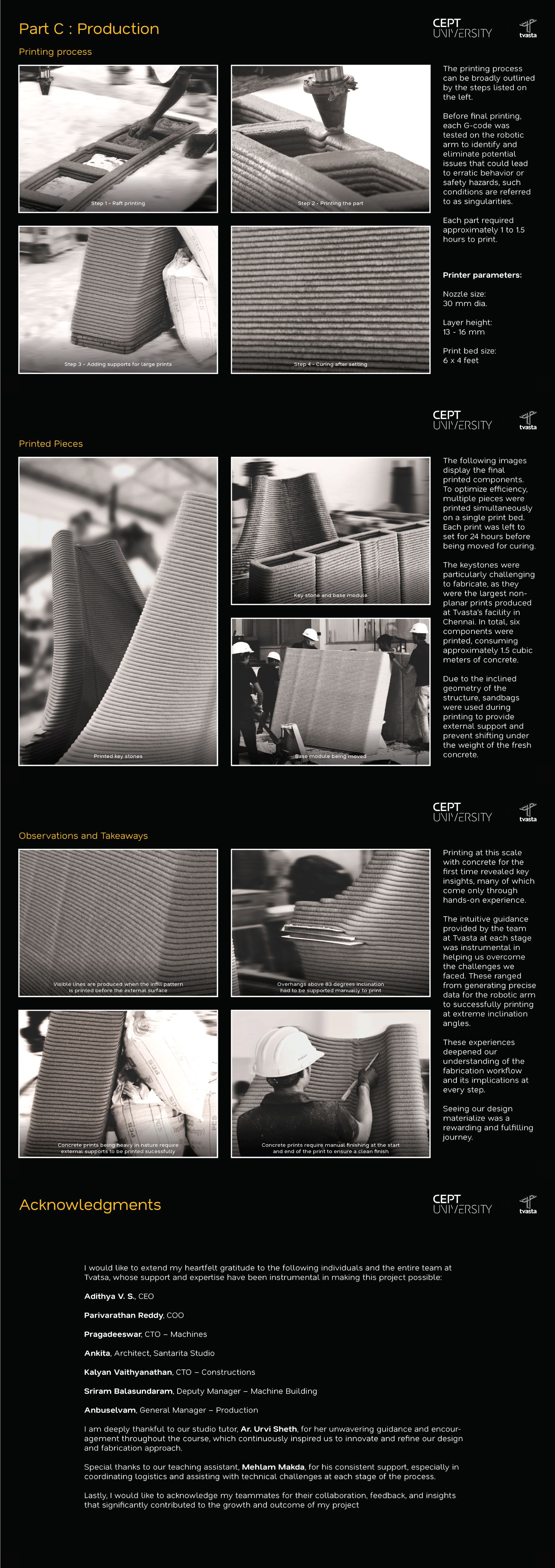

3D printing enables precise control over form, allowing the creation of smooth edges, hollow sections, and customized surface textures ideal for acoustic optimization.

While concrete is a strong insulator and sound reflector, its density and typically smooth surfaces limit its ability to absorb sound.

This project explores how computational design can generate context-specific geometries and textures that enhance sound absorption and diffusion in 3D-printed concrete structures. By leveraging algorithmic design and digital fabrication, the study aims to optimize acoustic performance while integrating functionality with aesthetic expression in architecture.