Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

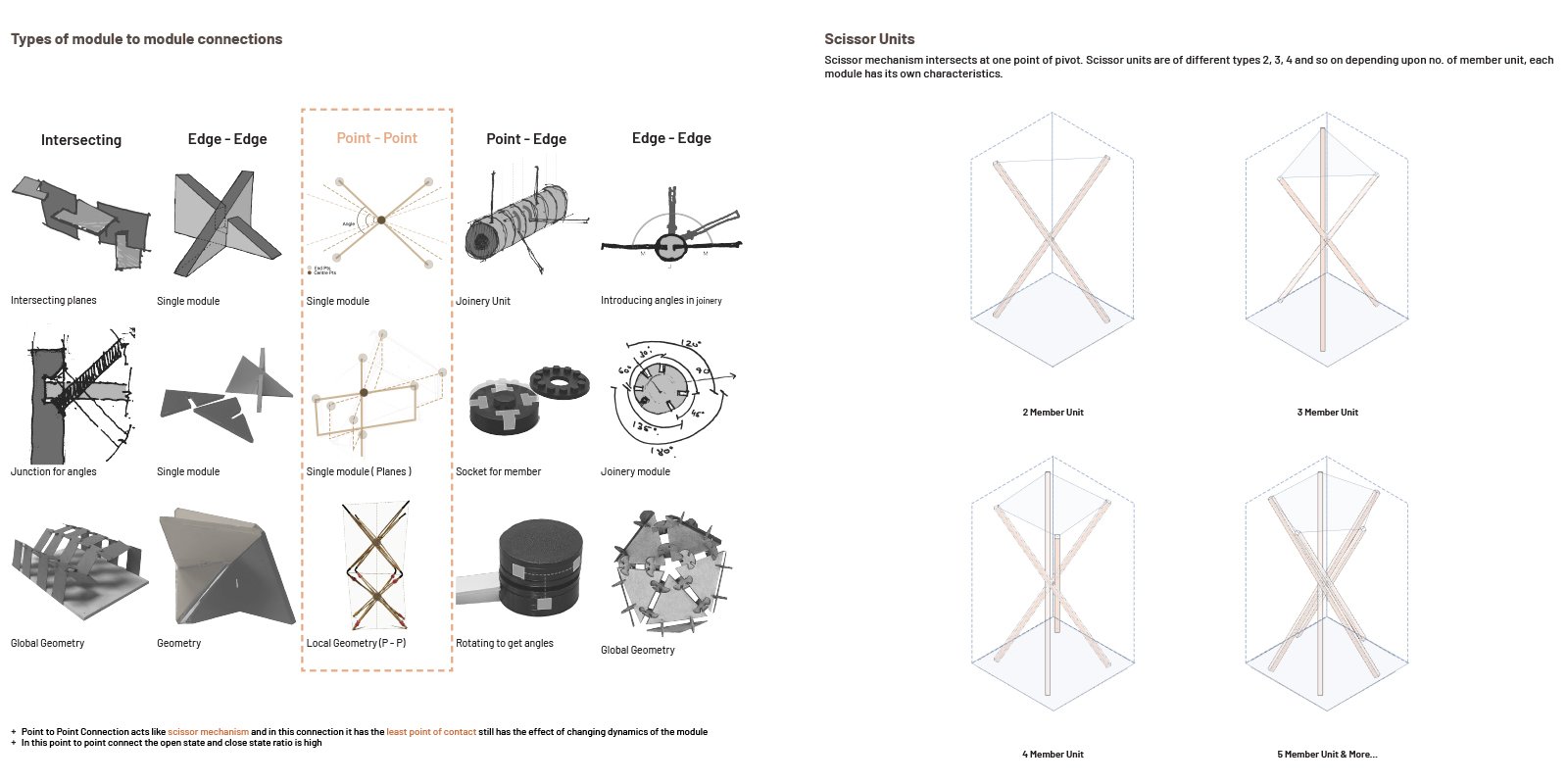

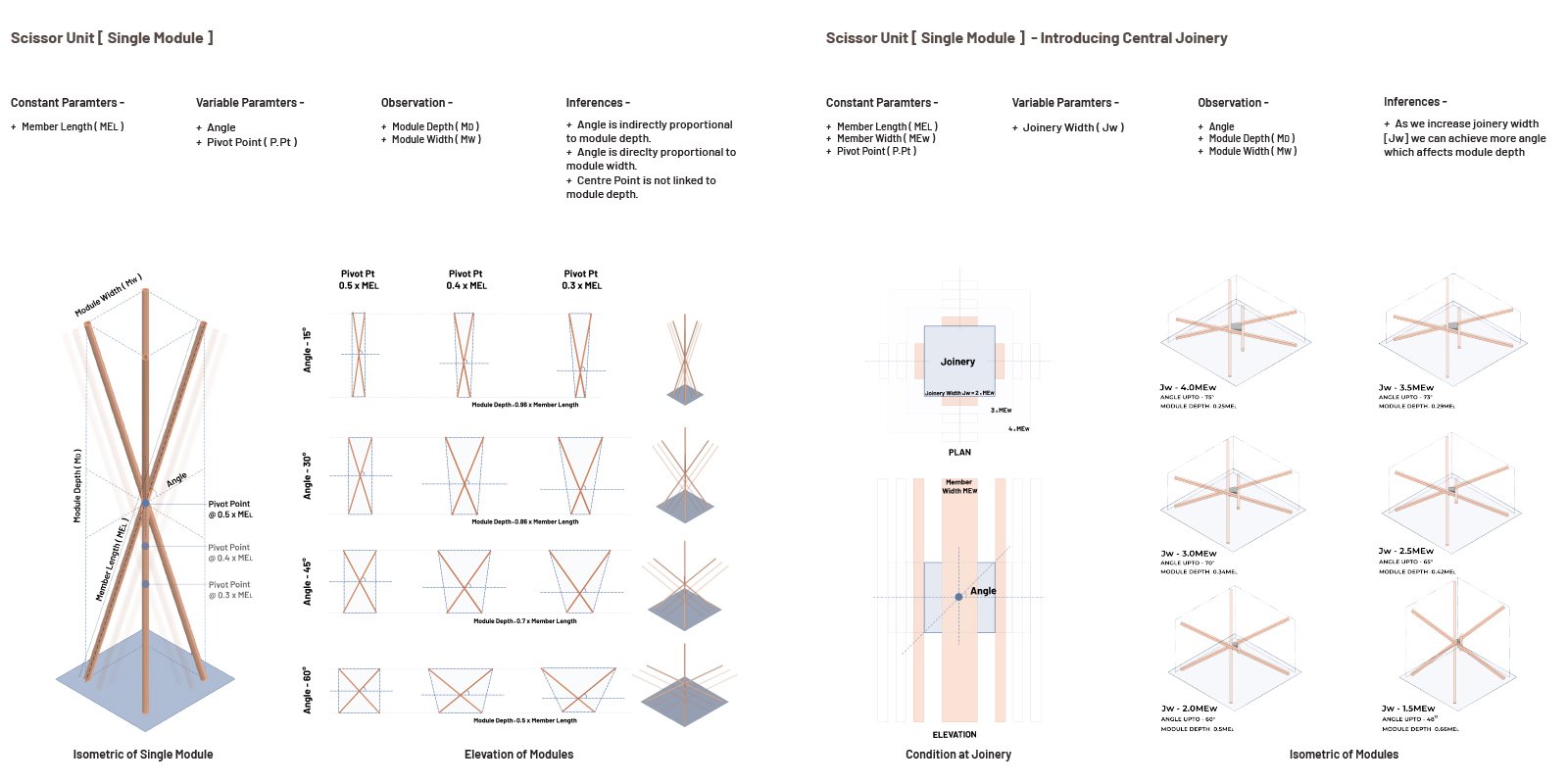

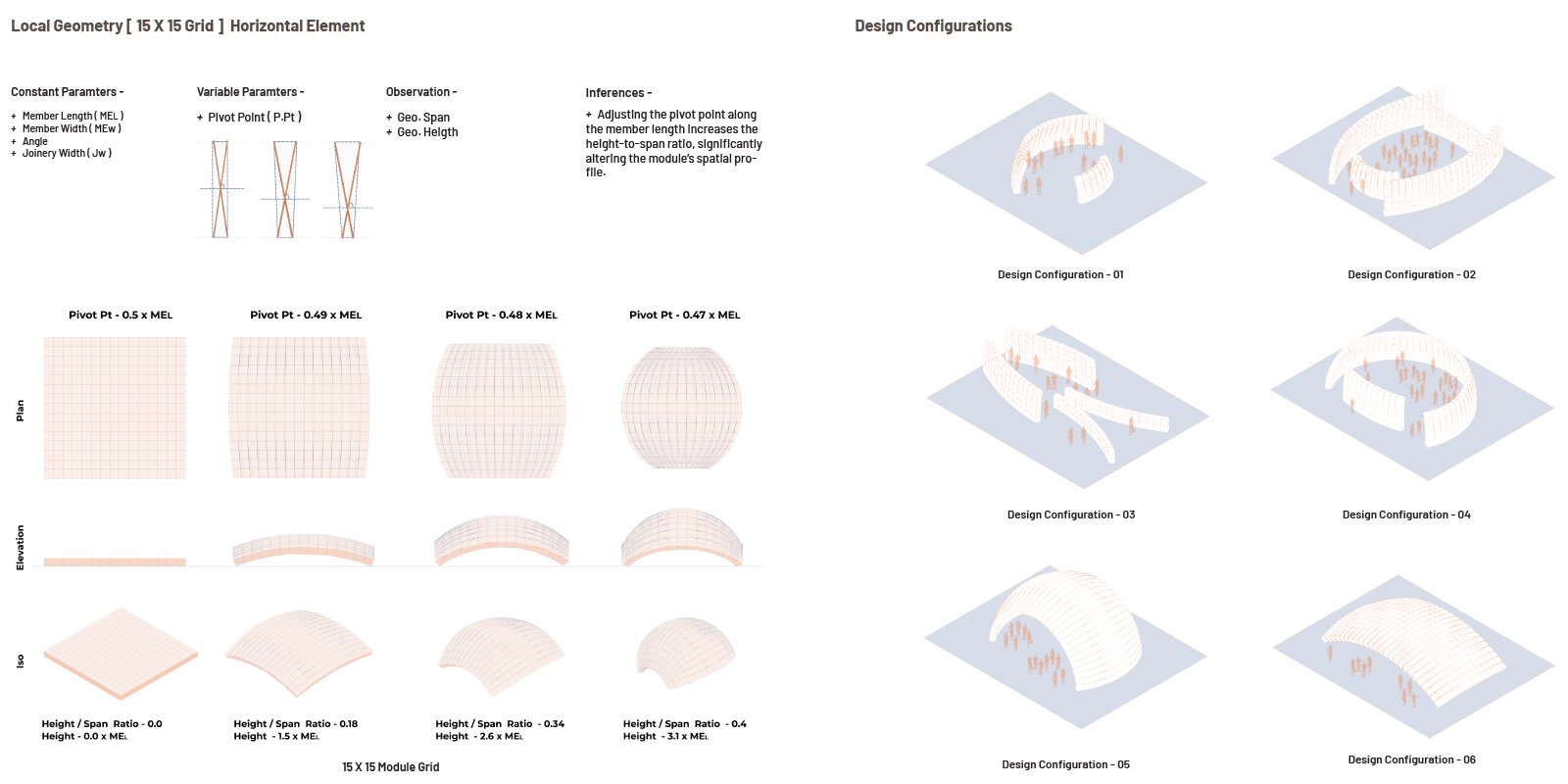

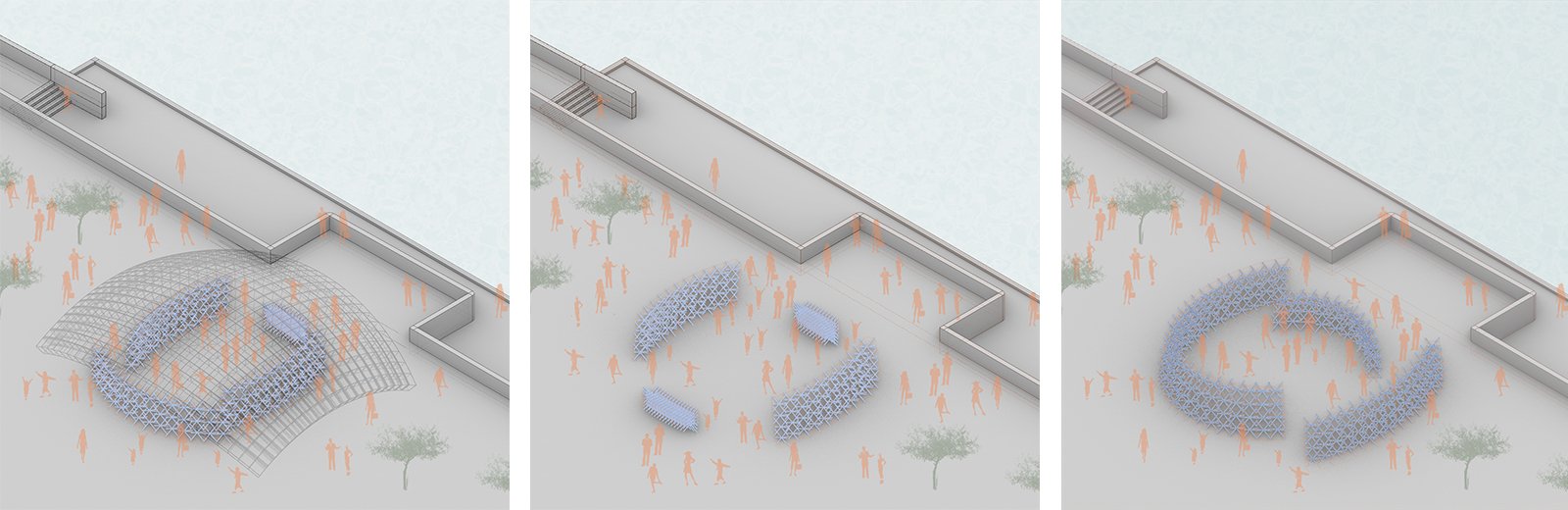

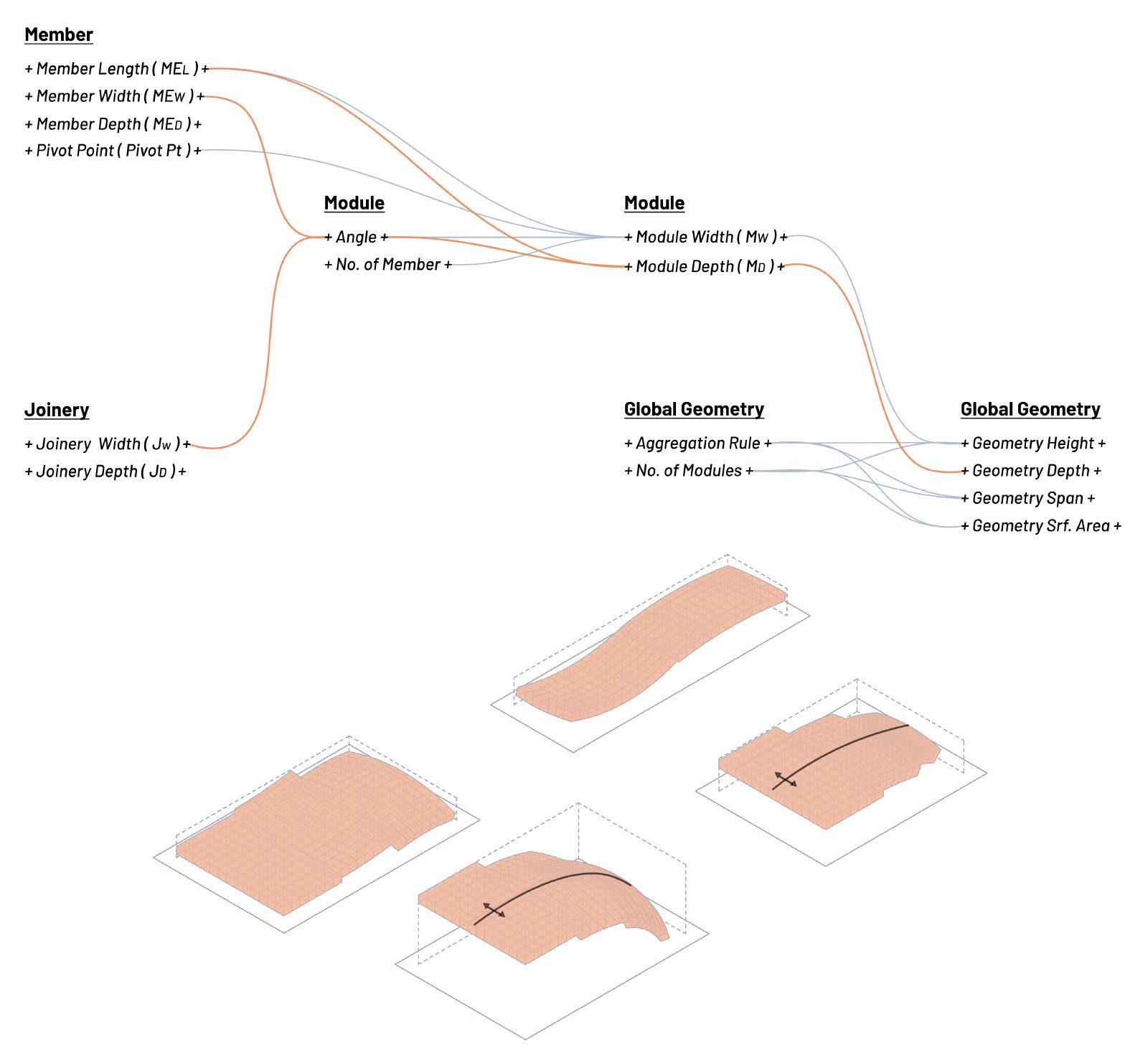

Project explores a modular system designed for functional adaptability through parametric control. Starting with module-to-module connection strategies, a point-to-point (scissor-like) mechanism was selected for its geometric influence and minimal connection requirements. While pivot position alters the module’s geometry, the angle critically impacts its spatial depth. At a larger scale, the aggregation of modules reveals how parametric inputs shape global geometry and enable flexibility. This adaptable framework lays the foundation for evolving the system into more complex spatial configurations, including curved and doubly-curved forms.