Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

Development of scaffolding clamps for bamboo

“If you think of standardization as the best you know today, but which is to be improved tomorrow; you get somewhere. “- Henry Ford

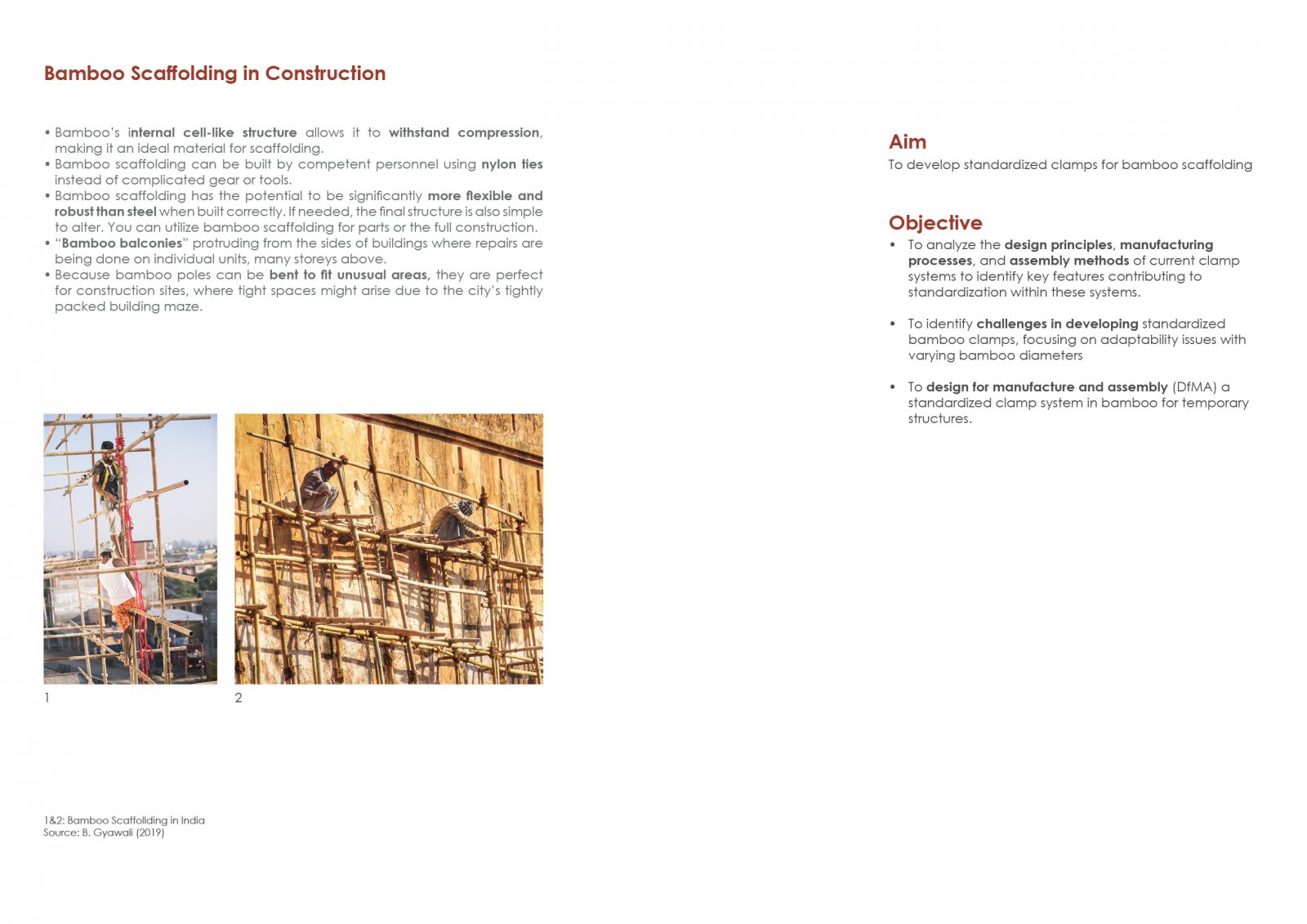

Bamboo, a versatile and readily available material, has been an integral part of construction in India for centuries. Its abundance, cost effectiveness, and eco-friendly properties have made it a popular choice, especially in temporary applications such as scaffolding.

Bamboo is a grass-type plant that has been used for generations in the construction industry,

because of its fast growth, structural integrity, lightweight properties, and economic benefits, it

makes an appropriate choice for a rapidly deployable structure. However, it needs an effective connecting system. ‘Due to its morphological characteristics, it is mainly used in the form of bamboo derivatives, for furniture production, flooring, and construction and civil

engineering’(Elejoste et al., 2020). The market’s overwhelming supply of treated bamboo, as

opposed to untreated bamboo, further limits its broad-scale applicability. This highlights the

need for innovative solutions to enhance bamboo’s adaptability and standardization in

construction.

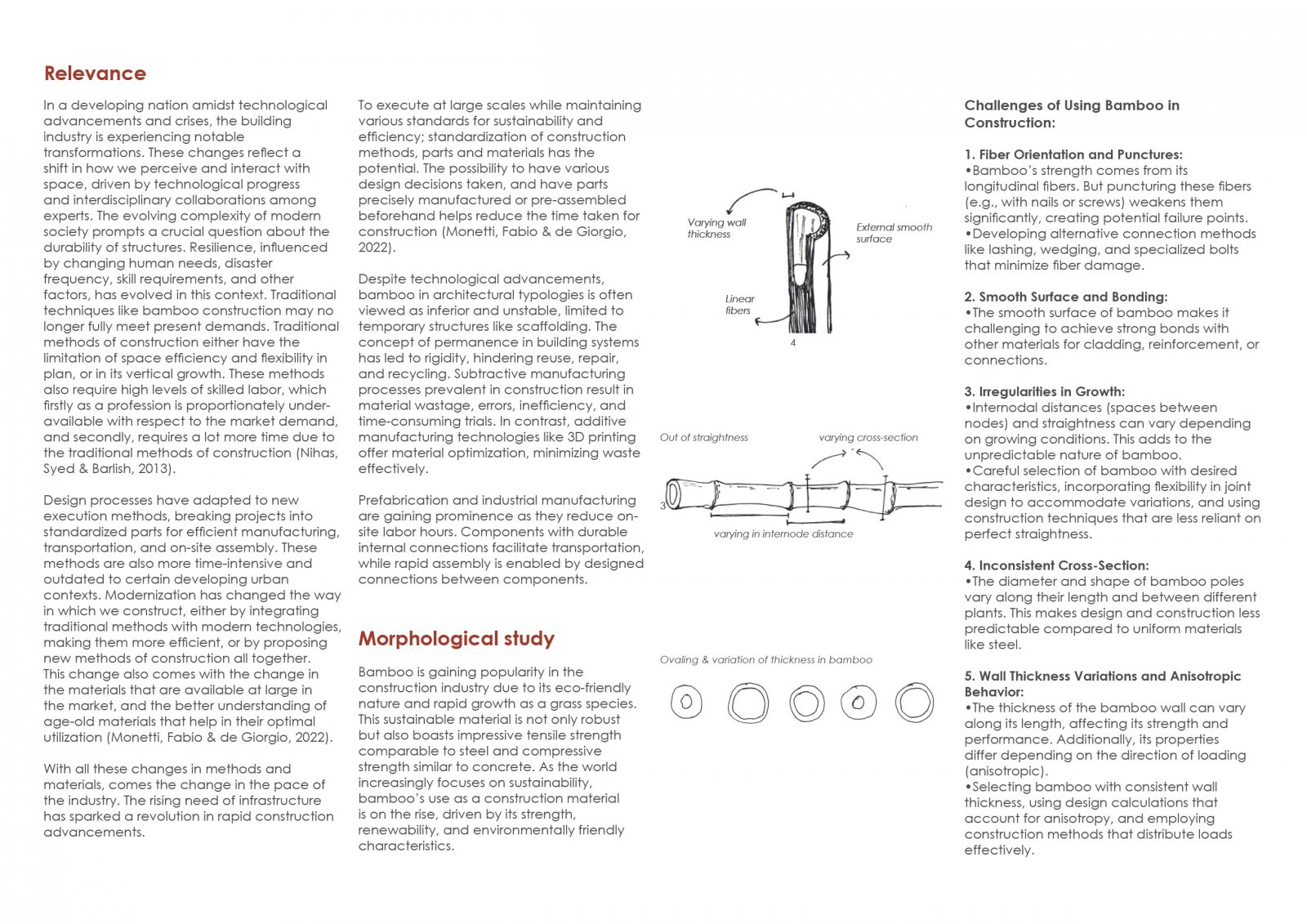

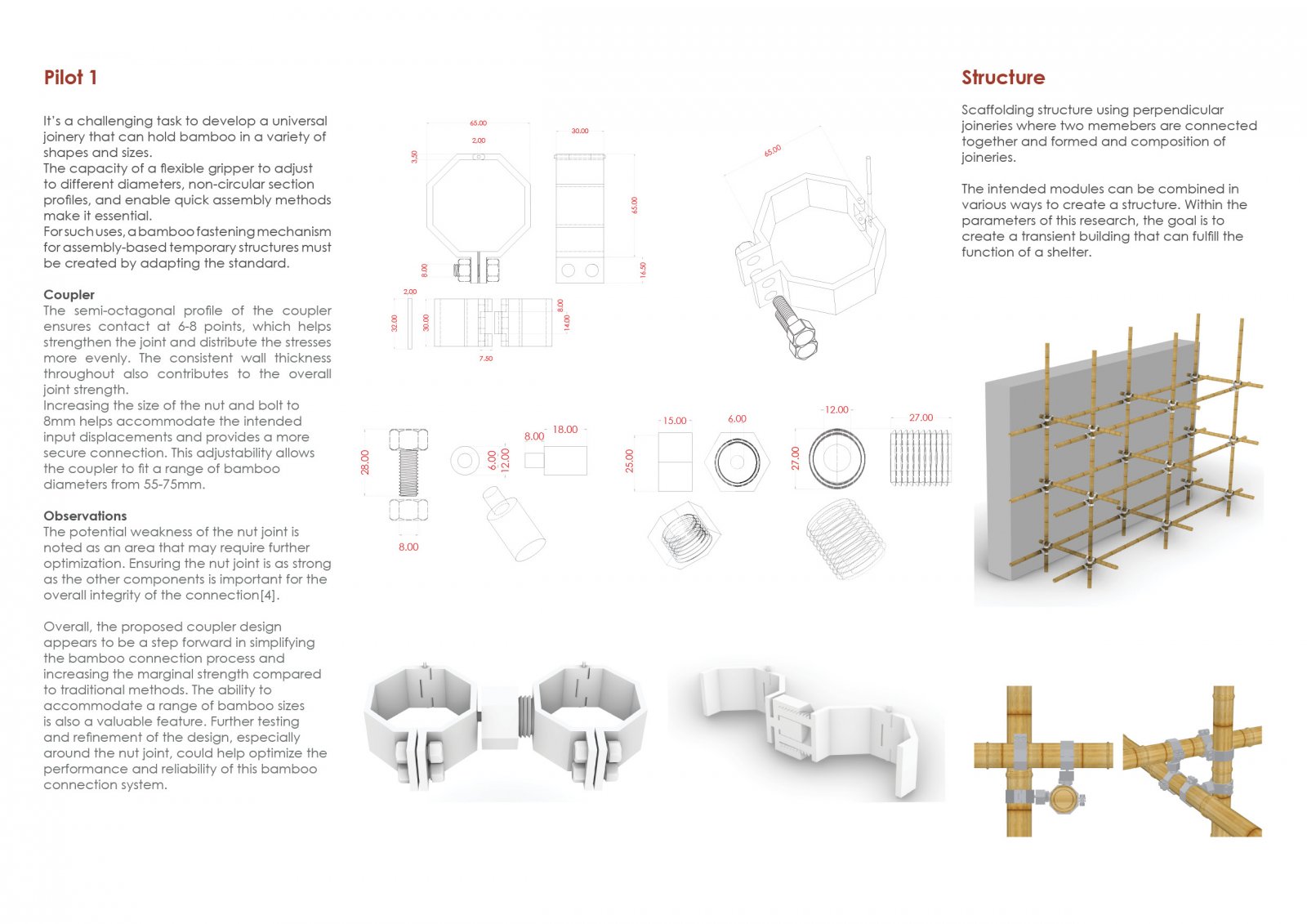

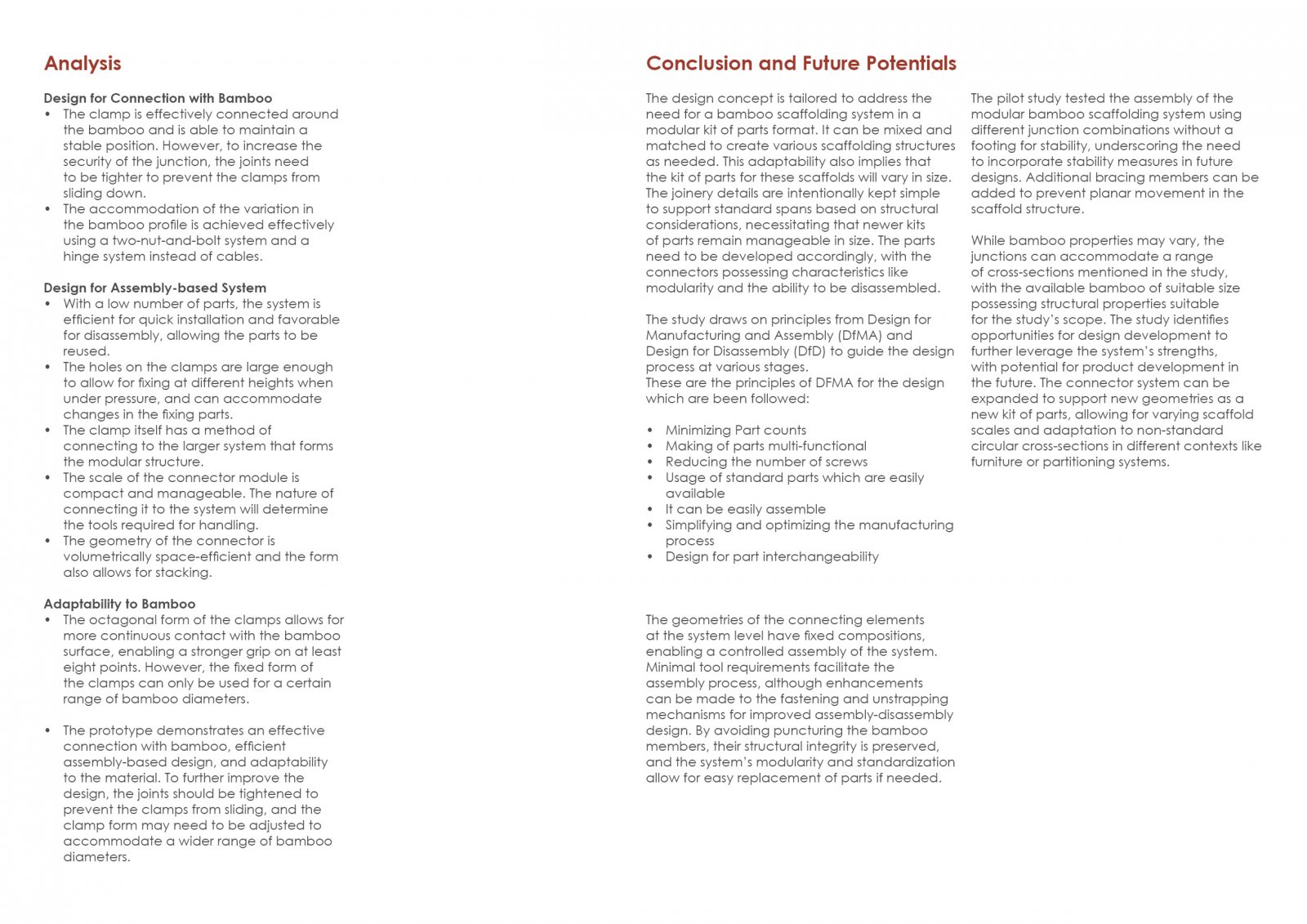

The core issue lies in the intricate detailing required for bamboo due to its varying diameter,

making the standardization of fastener systems challenging. Unlike steel or timber fasteners

that can be easily standardized, bamboo demands a unique approach. This research explores the pivotal issue of bamboo adaptability and delves into the development of standardized scaffolding clamps, aiming to revolutionize construction practices in India.