Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

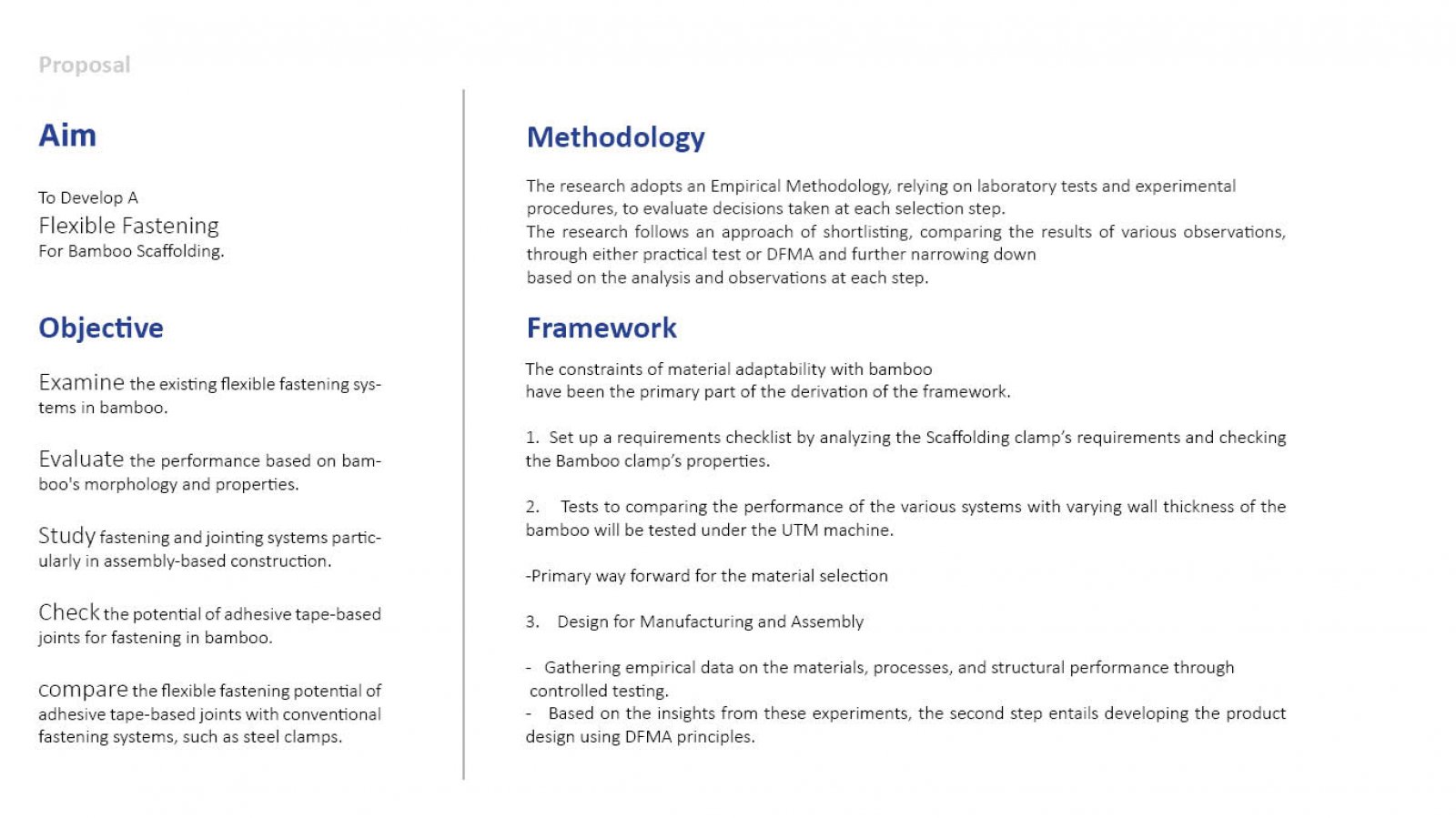

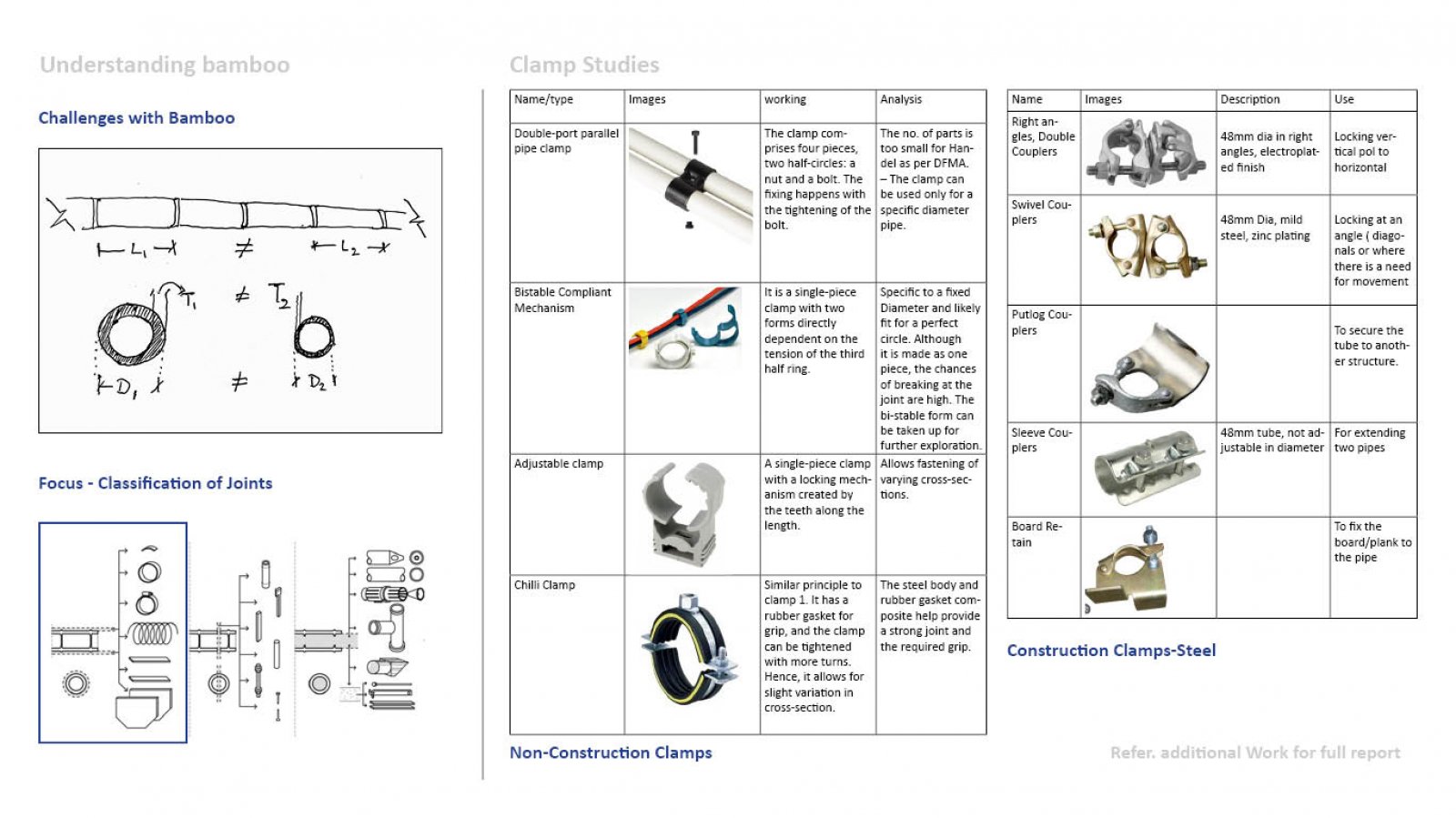

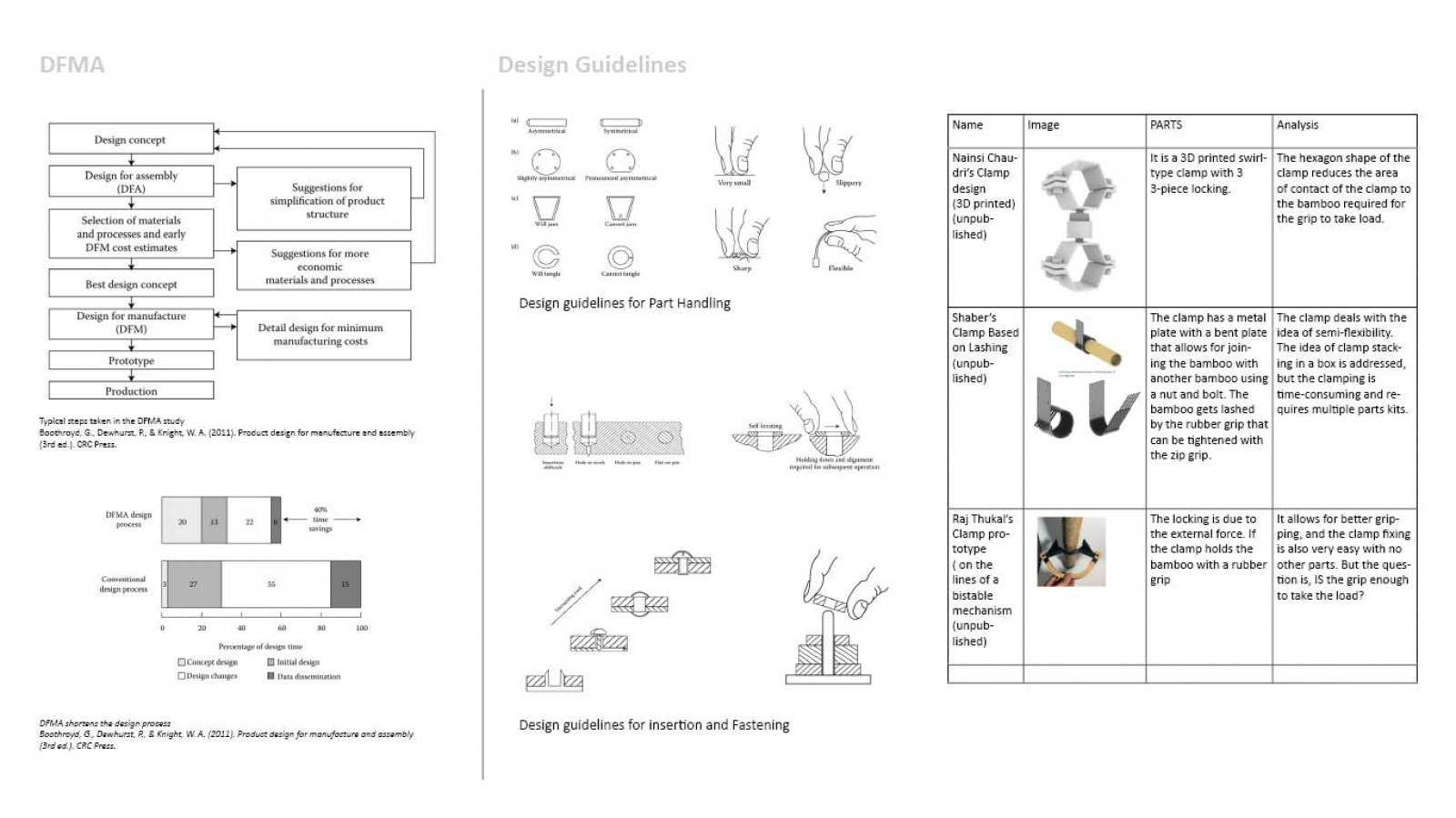

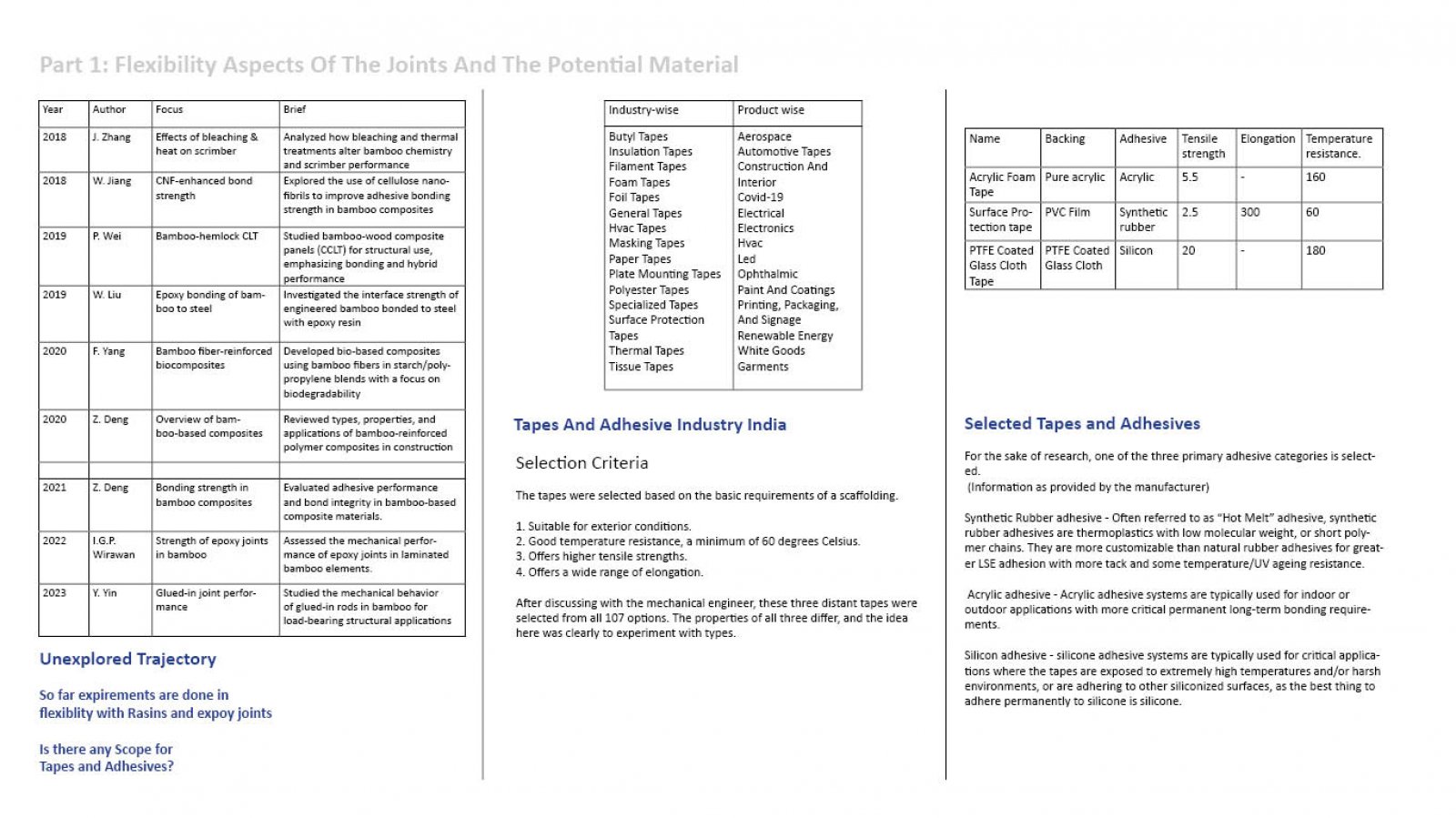

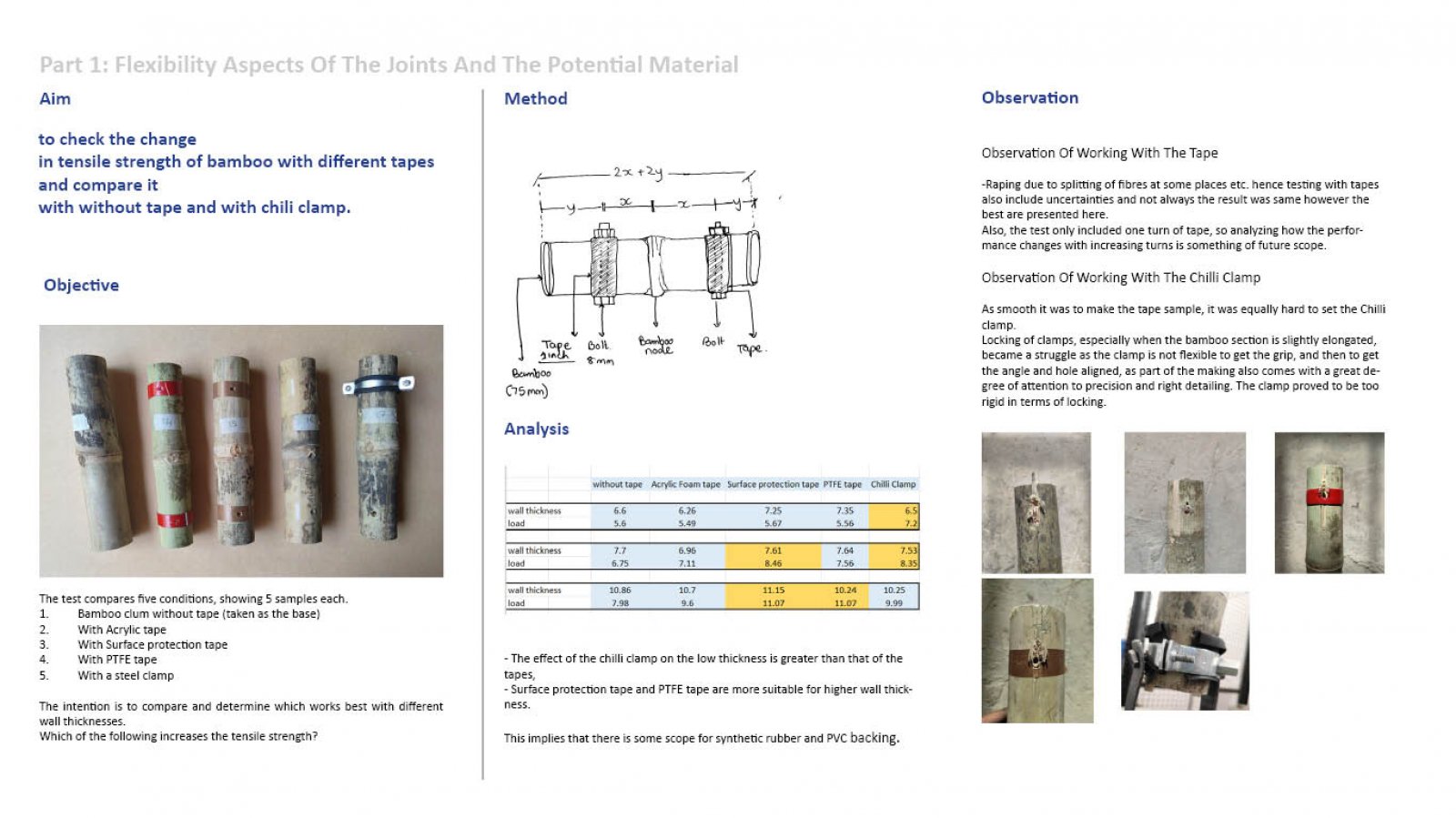

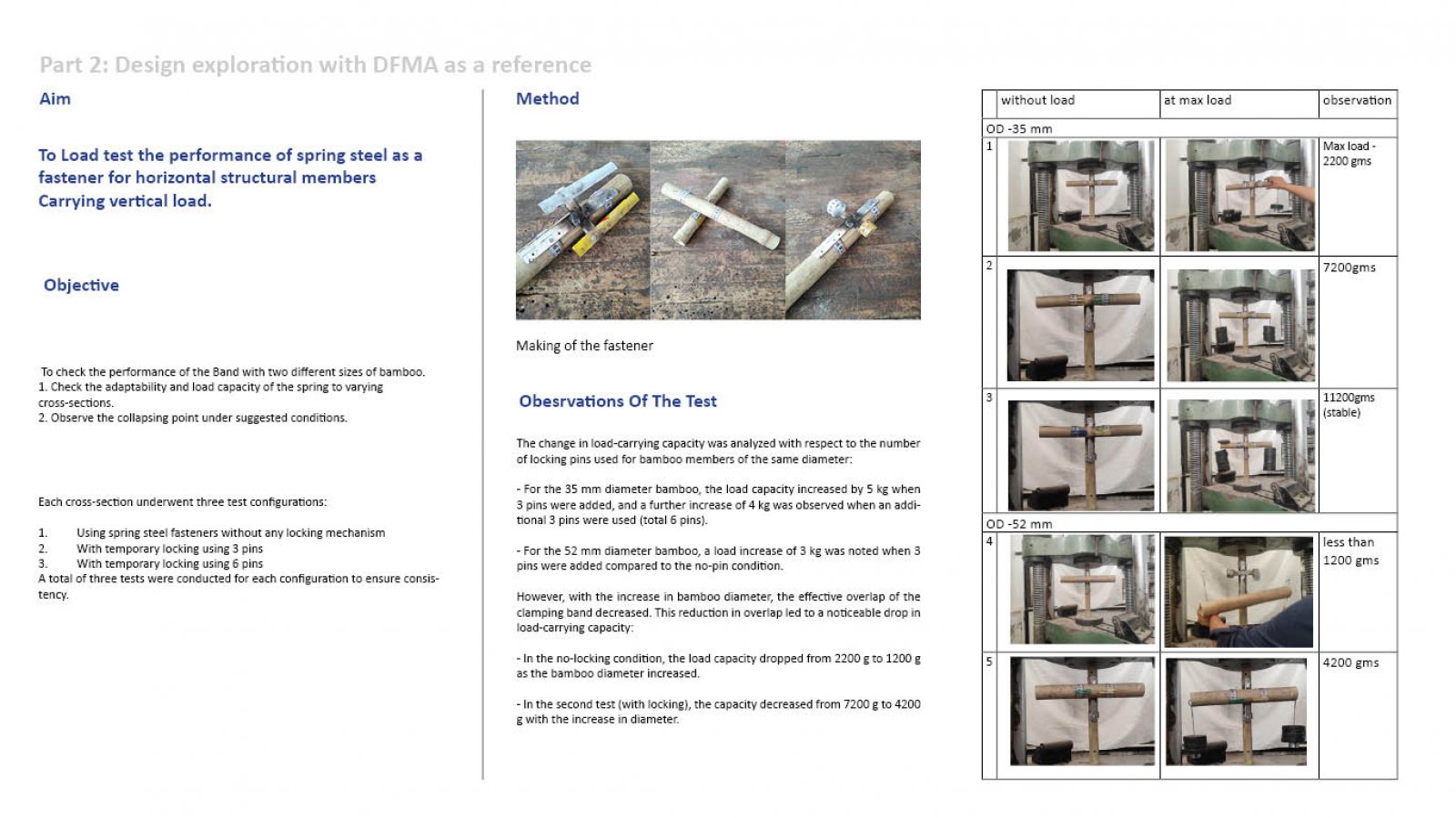

Bamboo is one of the most readily available natural materials across many regions. Its properties make it highly suitable for construction, such as a favorable strength-to-weight ratio, rapid renewability, and low environmental impact. However, its wider application is hindered by dimensional variability, susceptibility to weathering, and the absence of standardized handling and fastening techniques. Consequently, bamboo remains underutilized in mainstream construction despite its economic and ecological advantages. The most widely used bamboo is in the scaffolding system. As per a survey, bamboo scaffolding accounted for over 95% of scaffolding usage in private sector construction as recently as 2011. Bamboo is increasingly being replaced by steel and mixed-material alternatives due to concerns over safety, speed of assembly, and durability (Pitroda, 2013). Nonetheless, surveys indicate that many workers still regard bamboo scaffolding as more user-friendly than metal alternatives (Pitroda, 2013), particularly in second-tier cities like Rajkot, Kochi, and Vizag, where traditional knowledge remains embedded in construction practices. This research addresses a critical gap in developing engineered joinery systems for bamboo, focusing on flexible fastening as a potential solution to enhance structural performance and scalability. The primary aim is to investigate the architectural and structural viability of flexible joinery in bamboo, with particular emphasis on its application in modular and temporary structures. The methodology integrates literature review, experimental testing, physical prototyping, and sustainability assessment. The research is organized into five chapters, beginning with contextual framing, followed by case studies, results, and analysis, and concluding with a discussion on the implications and potential directions for future work