Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

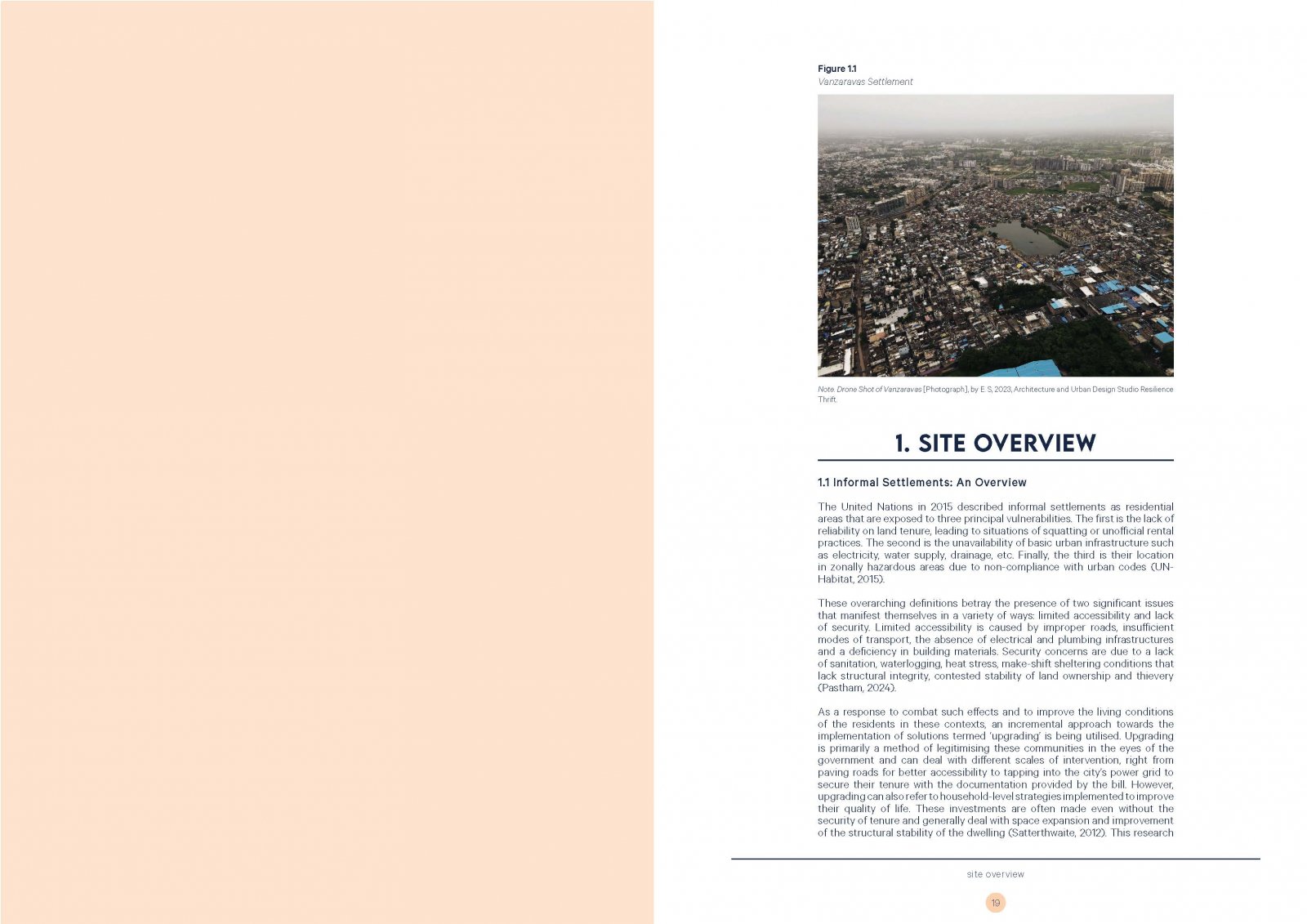

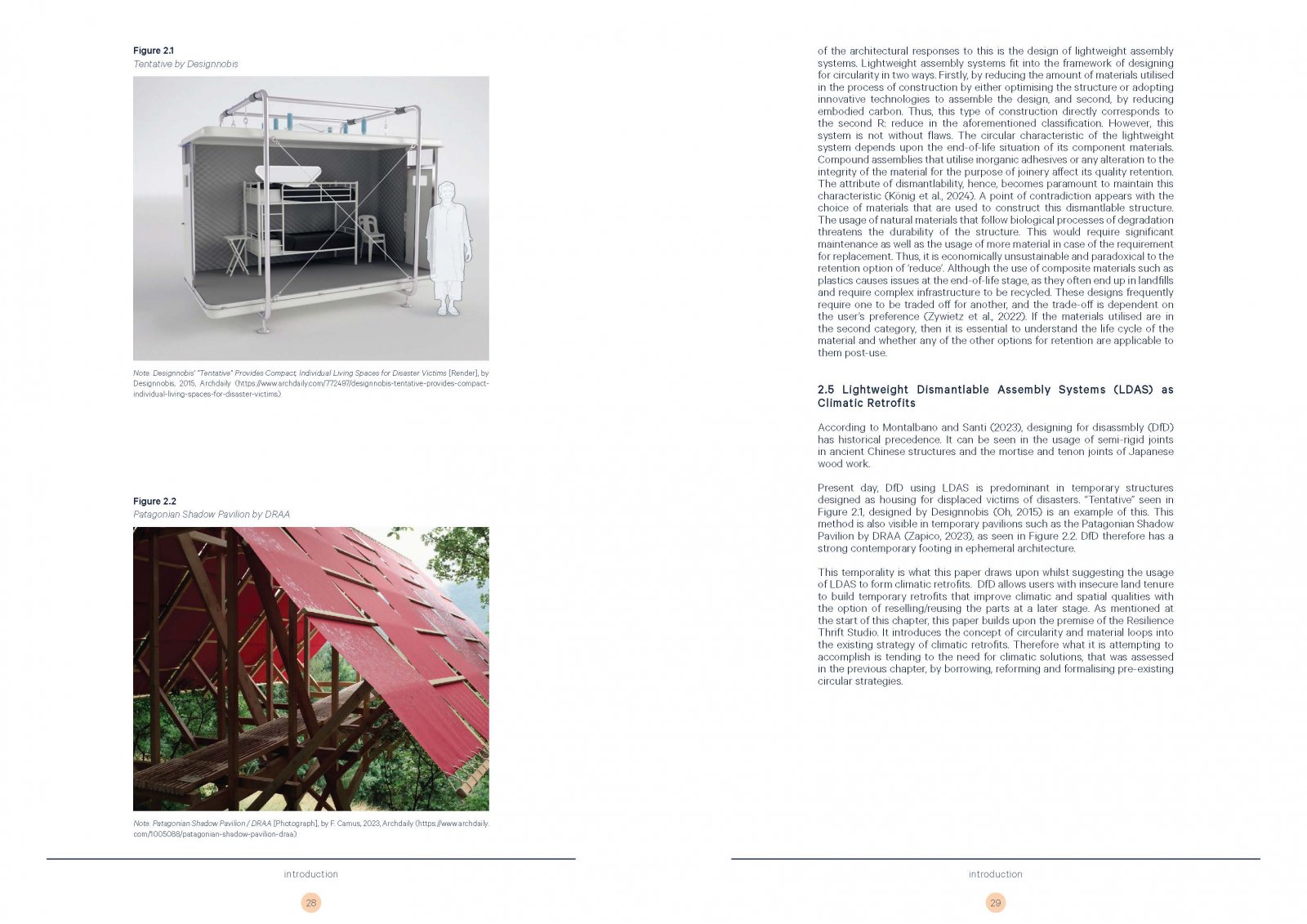

Informal settlements have become a ubiquitous component of the Indian urban sphere, as the development of formal housing fails to match the pace of rapid urbanisation. The inhabitants of these contexts are subject to numerous vulnerabilities caused by various phenomena, whether political, social or environmental. This paper follows the premise of the work done in the Studio Resilience Thrift at the Faculties of Architecture and Urban Design at CEPT University in the Monsoon 2023 and 2024 semesters, in which students designed retrofits for existing structures in the informal settlement of Vanzaravas to adapt them for climate change. This research analyses the various types of lightweight assembly systems through which these retrofits can be realised. Retrofitting as a solution promises a less wasteful endeavour in terms of materiality, construction and cost, as well as higher viability by reducing the requirement for bureaucratic approval. Using dismantlable assembly systems optimises this option even further. Dismantlable systems open up the venue for material quality retention, thus allowing users to reuse and resell the parts, directly benefiting those with unreliable land tenures. This method aligns with both the pre-existing practice of incremental additions and the pre-established circular economy that works on-site at the grassroots level. This research aims to develop a matrix that can be used to conceptualise climatic retrofits constructed using lightweight dismantlable assembly systems. To achieve this, the paper utilises the following method. First, the existing housing typologies in Vanzaravas are classified and drawn diagrammatically to be later used as parameters for design. Secondly, existing climate-responsive strategies on-site are observed and drawn. Based on this and the work of the studios Resilience Thrift 2023 and 2024, possible classifications for climatic retrofits are derived and diagrammed. These retrofits are paired with the parameters of existing site typologies to understand what on-site conditions suit their establishment. Next, the research examines possible construction methods which could be used to arrive at diagrammatic solutions. Six case studies, two from the site and four from around the world, are selected as examples that prioritise assembly and disassembly and, therefore, enable circular construction. These case studies were observed, analysed through drawings and separated into their constituent constructional elements to derive different systems of assembly. The construction details of the case studies have been deduced, conjectured and drawn by the author, for which there were photographs and general arrangement drawings, but no construction information. The only exception is the case of ‘Off the Shelf’, in which specific drawings were corrected using the construction drawings provided by the architect. Through this method, this research creates a set of information related to assembly systems that was not previously accessible. These derived systems are collated to form a taxonomy after being evaluated in terms of the kinds of circularity each of them enables using the 10R metric, which assesses potential for material quality retention. Following the same order of operations of analysis of case studies and then collation, material alternatives, to contextualise the materials used in these systems, are tabulated. Finally, all the gathered data is combined into a matrix from which elements can be extracted and collaged to arrive at conceptual designs. This matrix is aimed at architects and contractors familiar with the context of informal settlements to open up discussions about how retrofits for informal settlements can be constructed. Therefore, the matrix has been tested by a former student of Resilience Thrift to inculcate circularity into her concept. The expected outcome from this tool is not a replication of the analysed case studies, but rather a way to utilise the principles of these assemblies to gain a starting point for the design process.

View Additional Work