Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

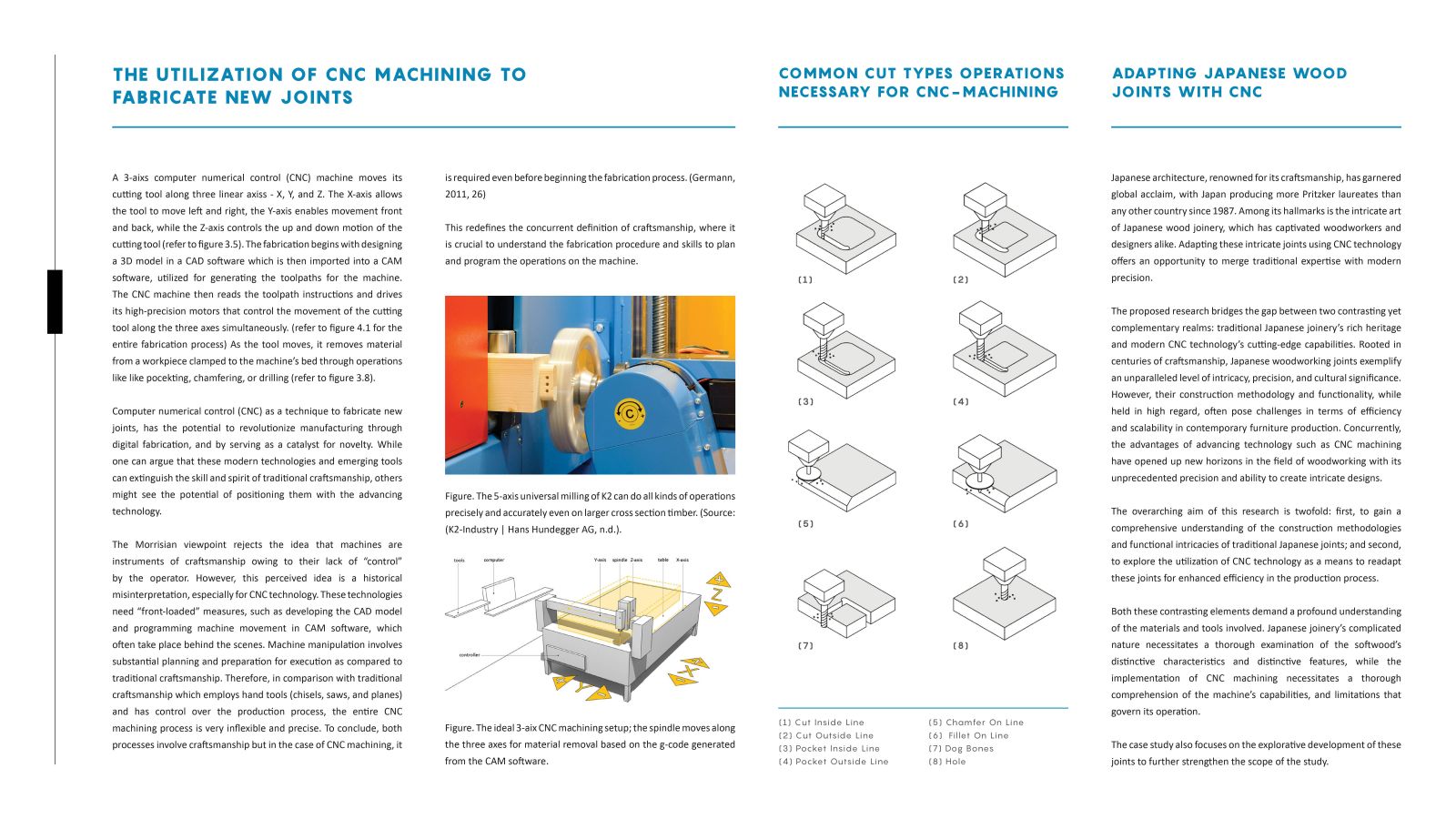

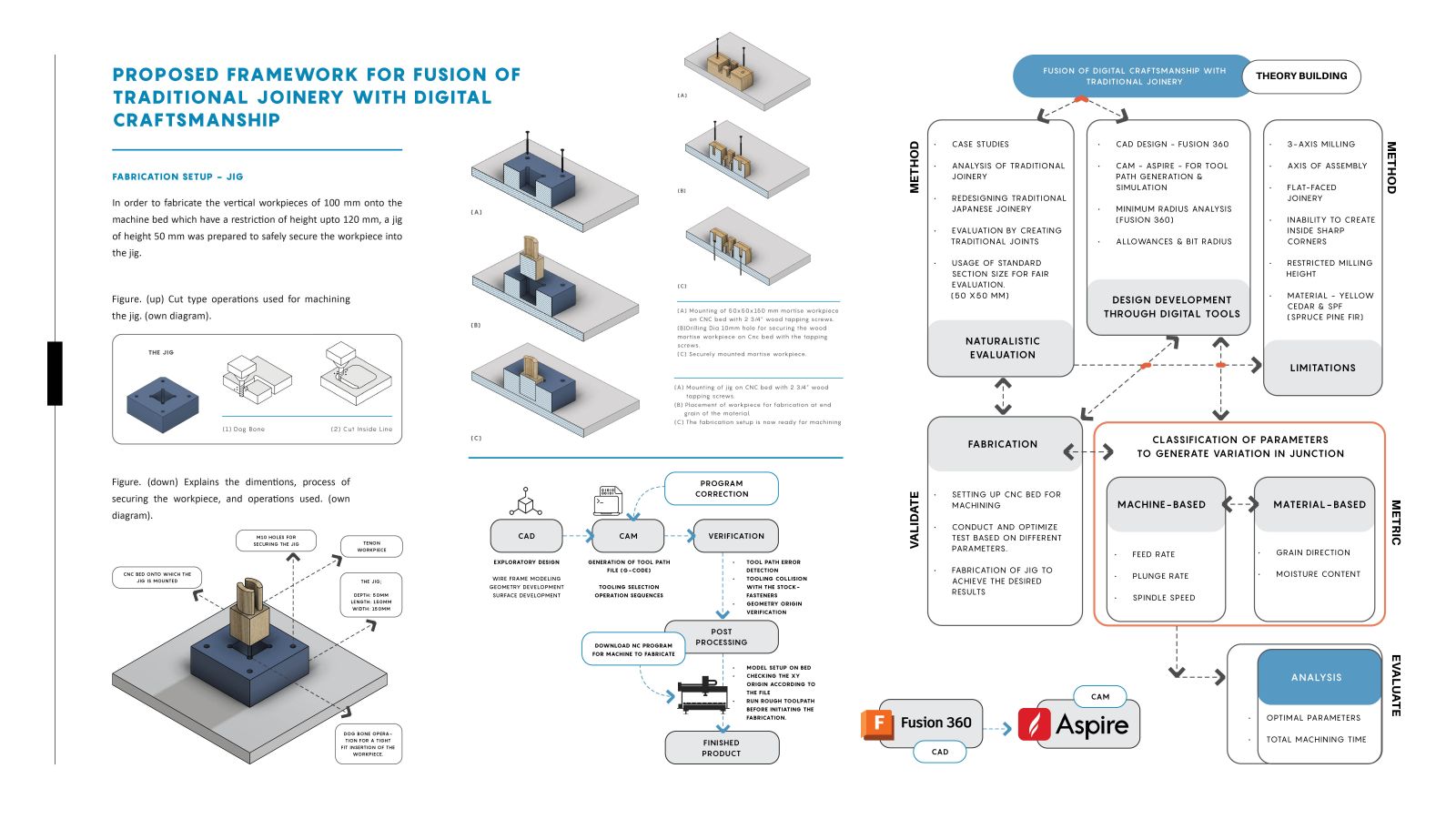

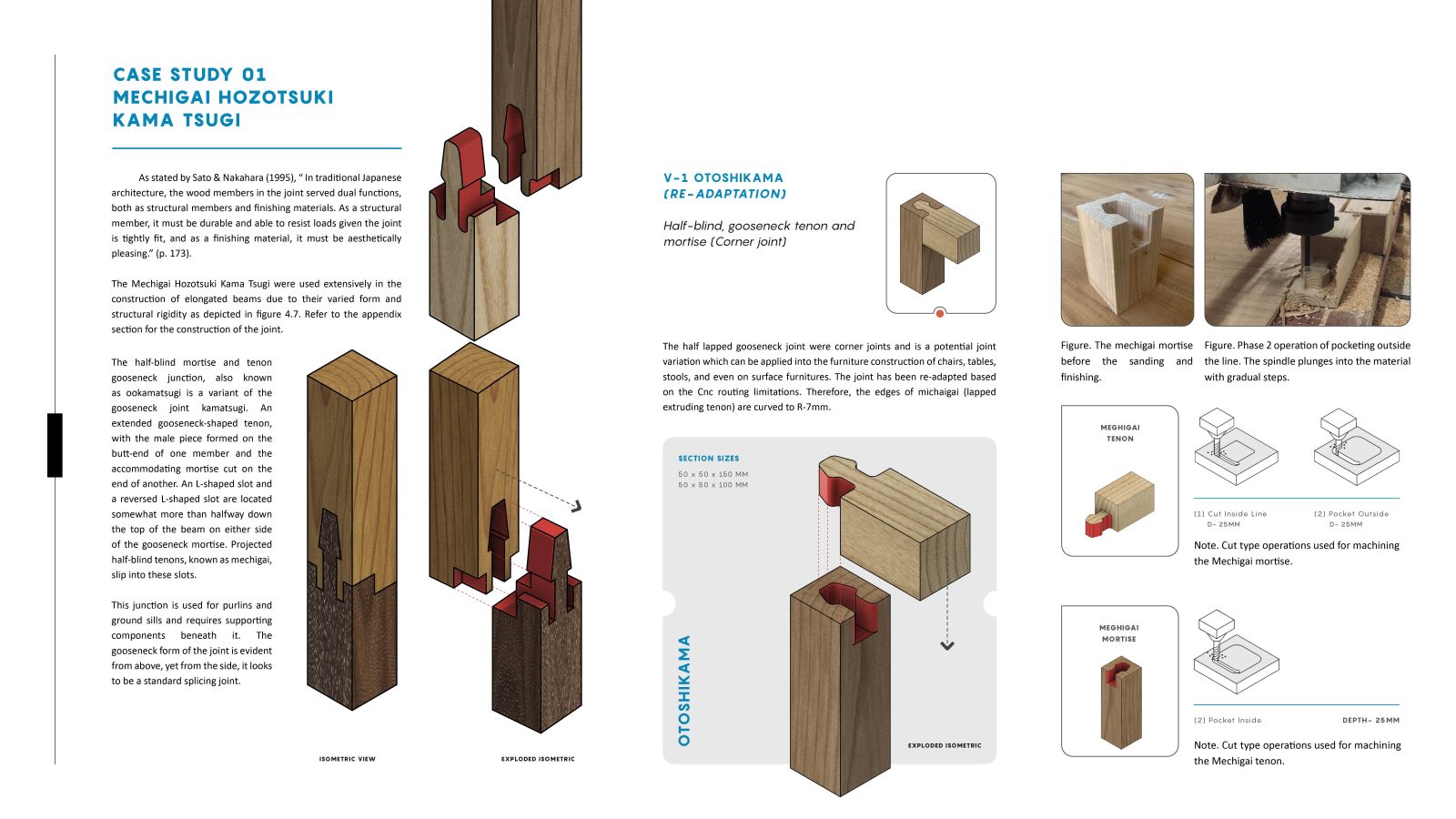

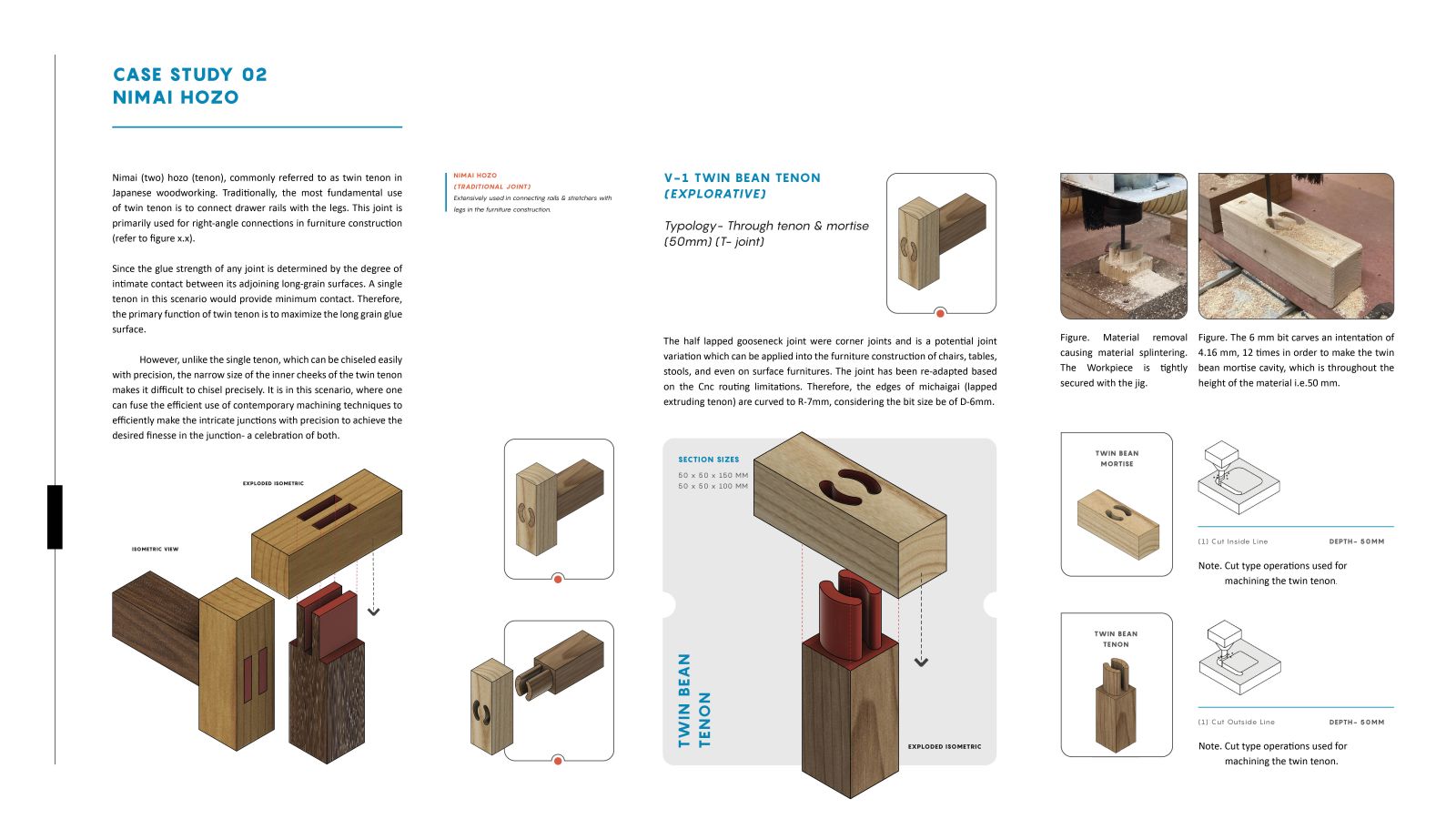

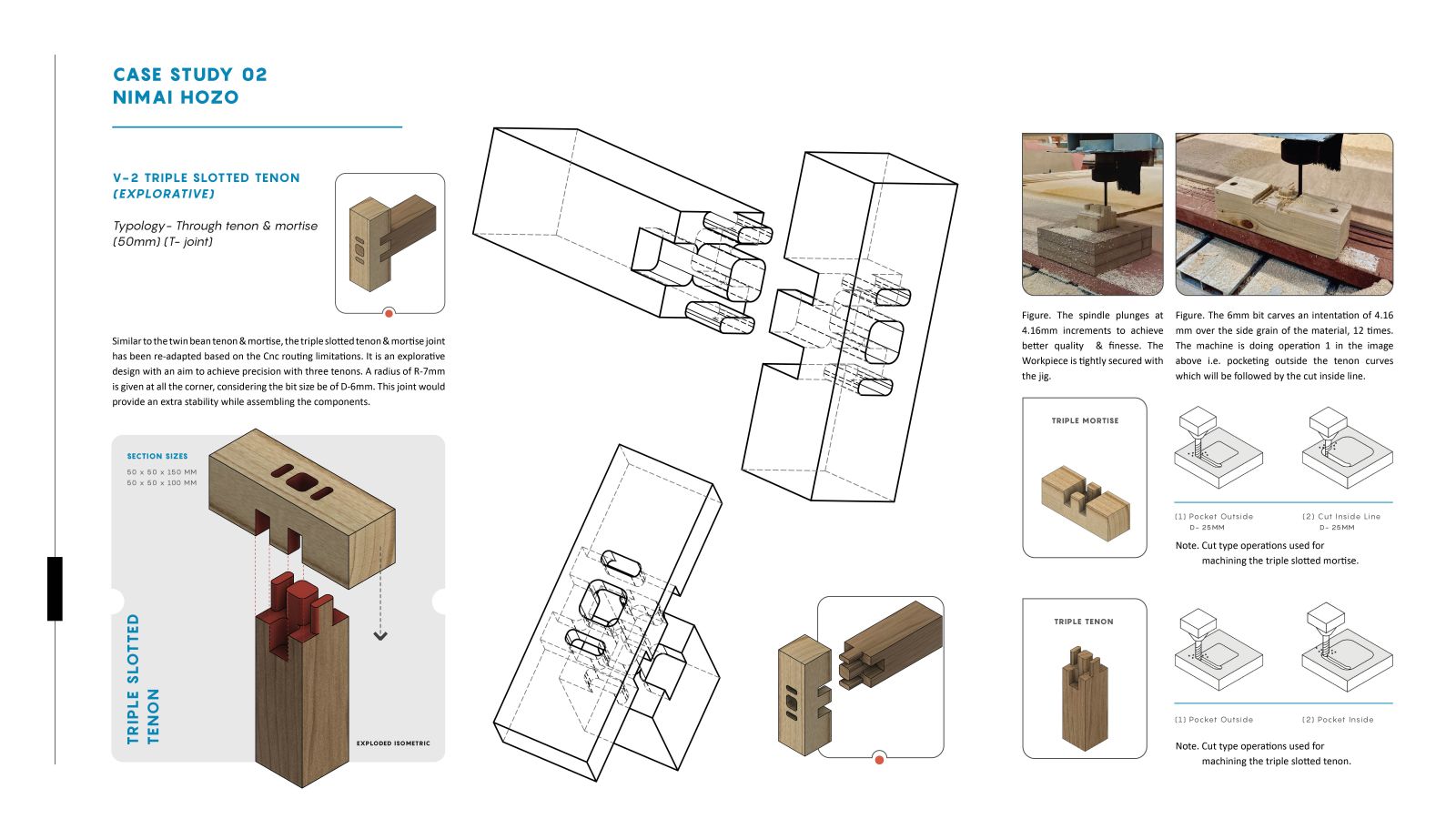

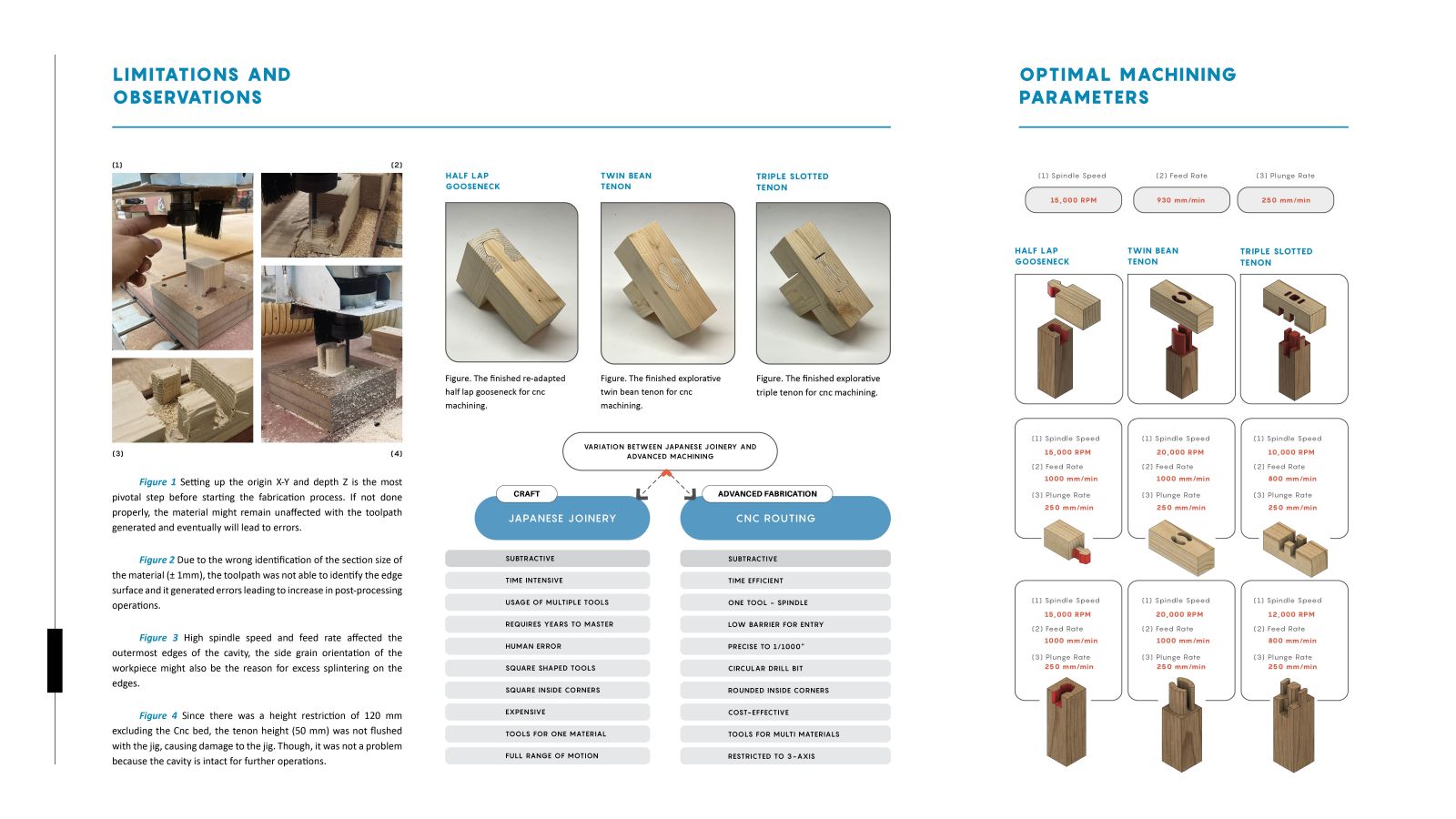

This research bridges the gap between traditional woodworking craftsmanship and advanced CNC machining for softwood furniture production. It aims to understand construction methodologies of intricate joints like Japanese Mechigai Hozotsuki Kama Tsugi and Nimai Hozo while exploring how CNC technology can re-adapt these joints for enhanced efficiency by optimizing parameters like feed rate, plunge rate, and grain direction. Case studies on species like Western Red Cedar and Douglas Fir will identify optimal parameters influencing production efficiency, precision, and joint performance - integrating time-honored techniques with modern manufacturing capabilities.

View Additional Work