Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

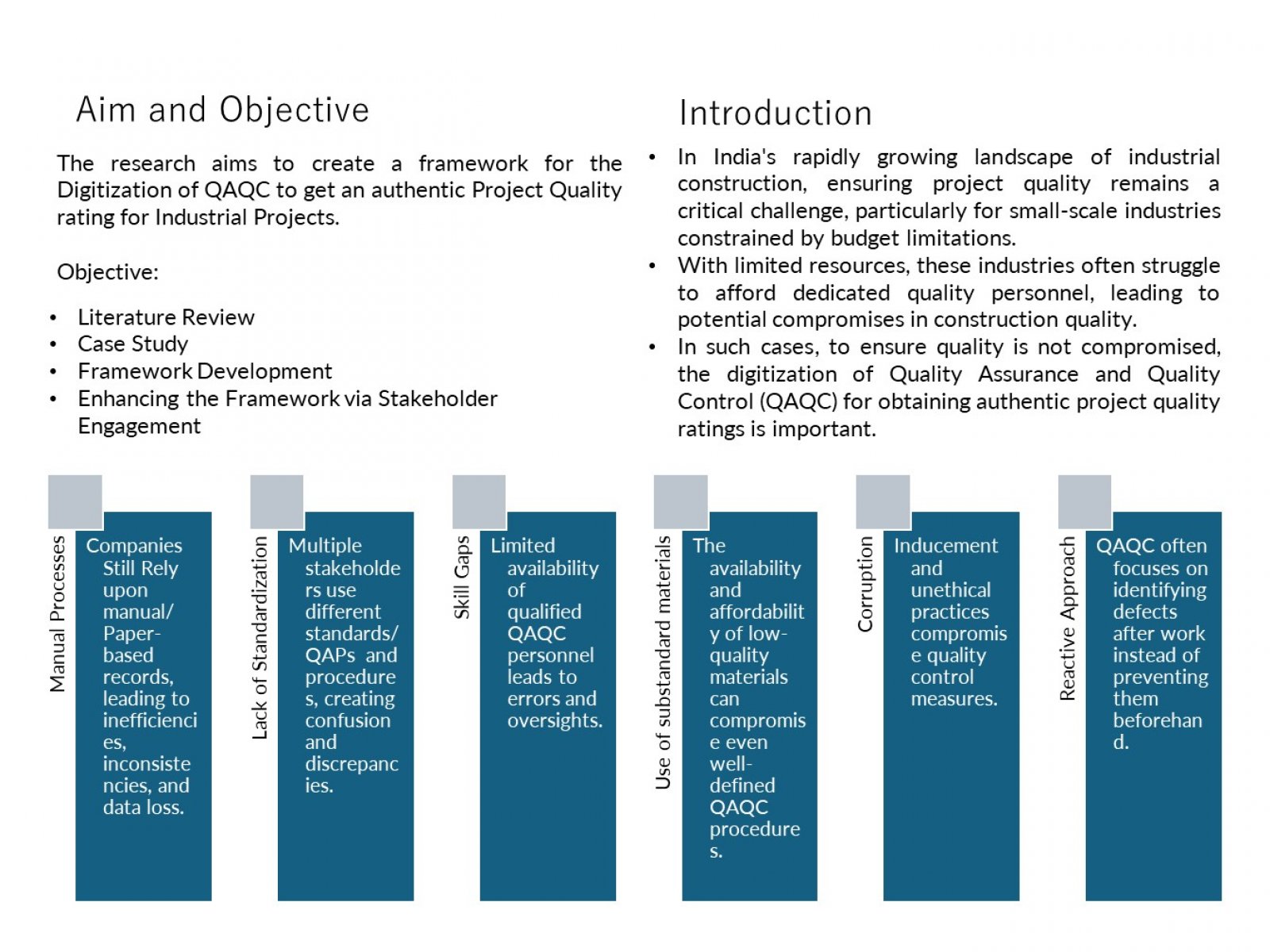

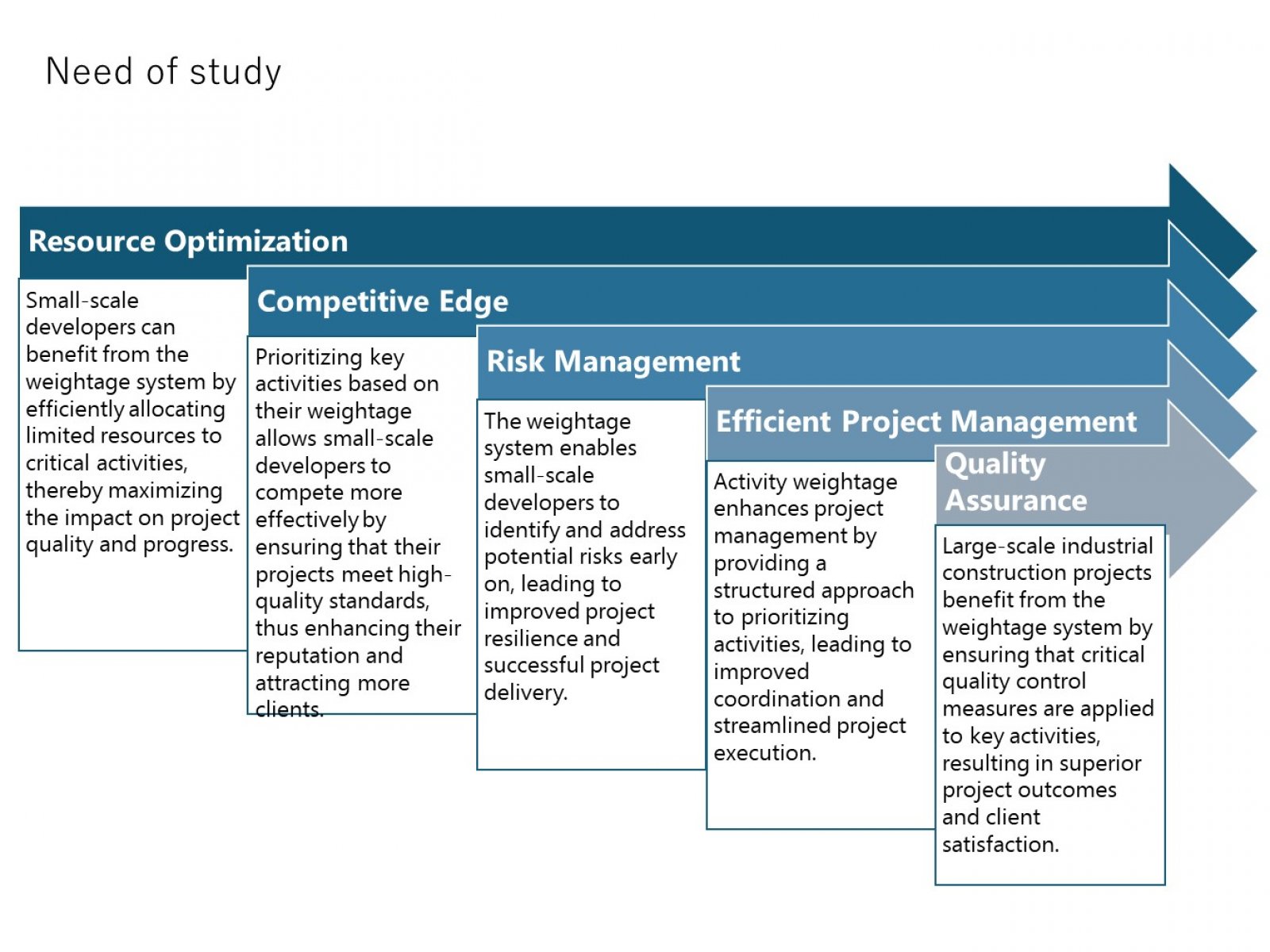

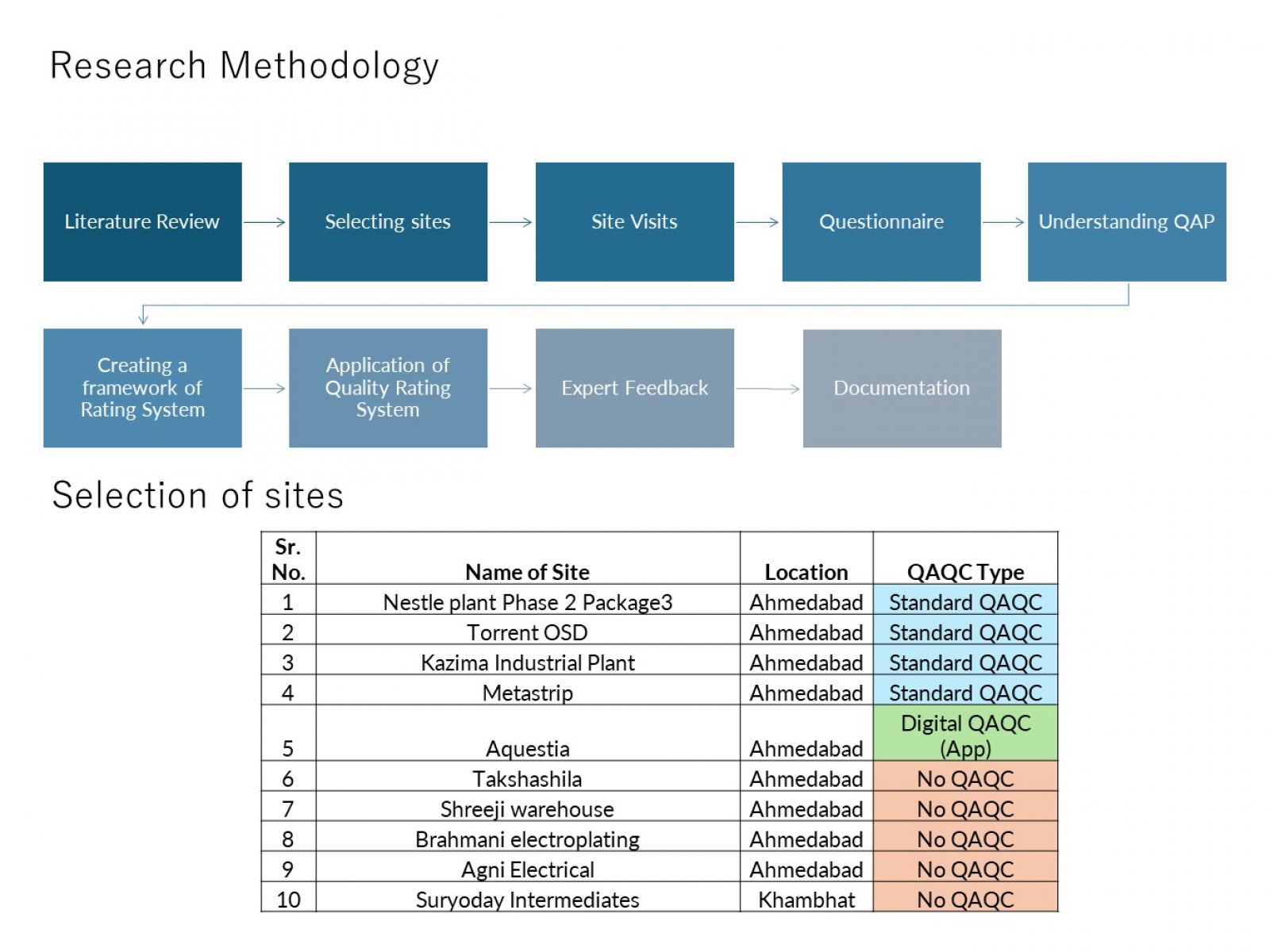

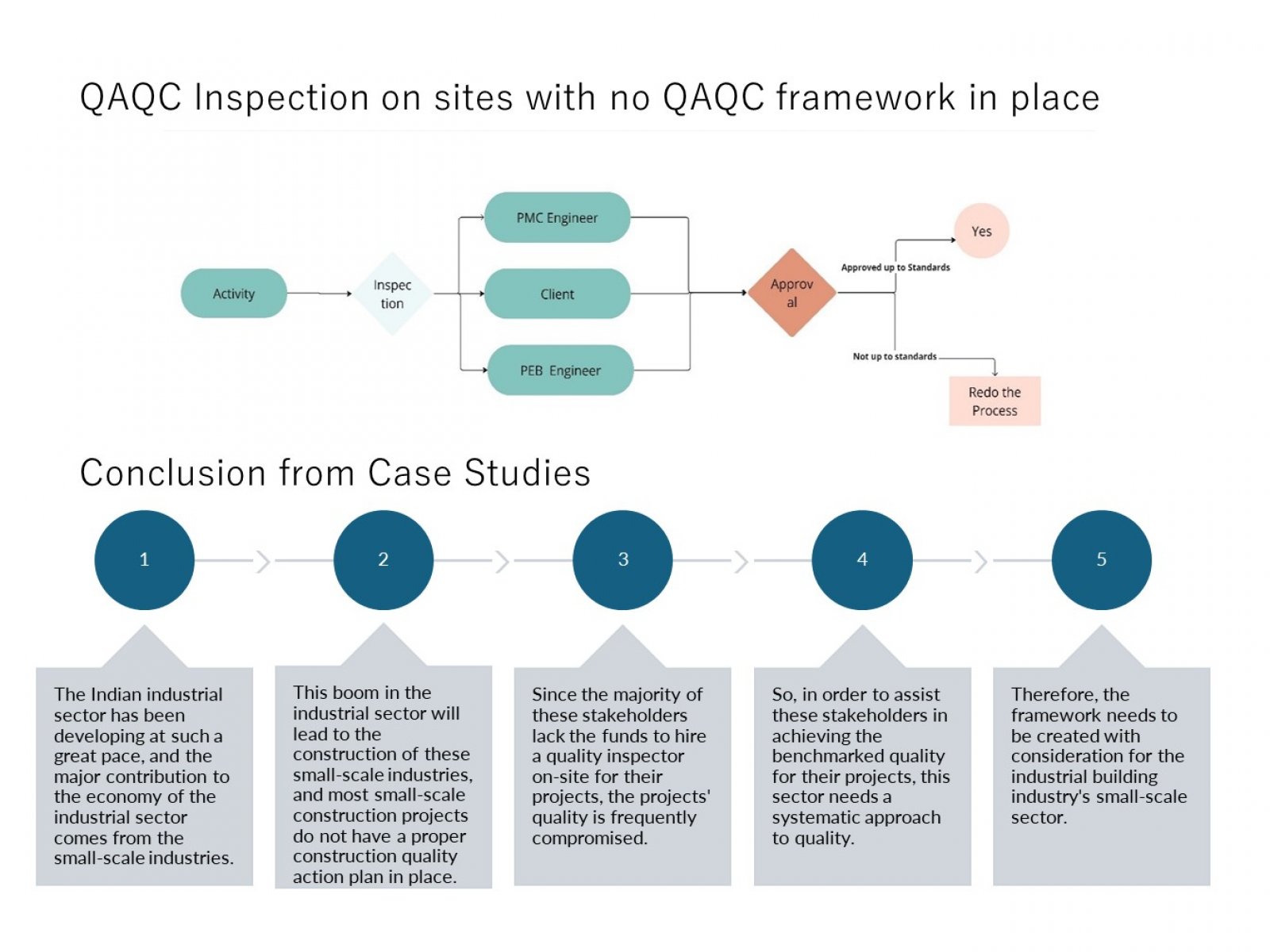

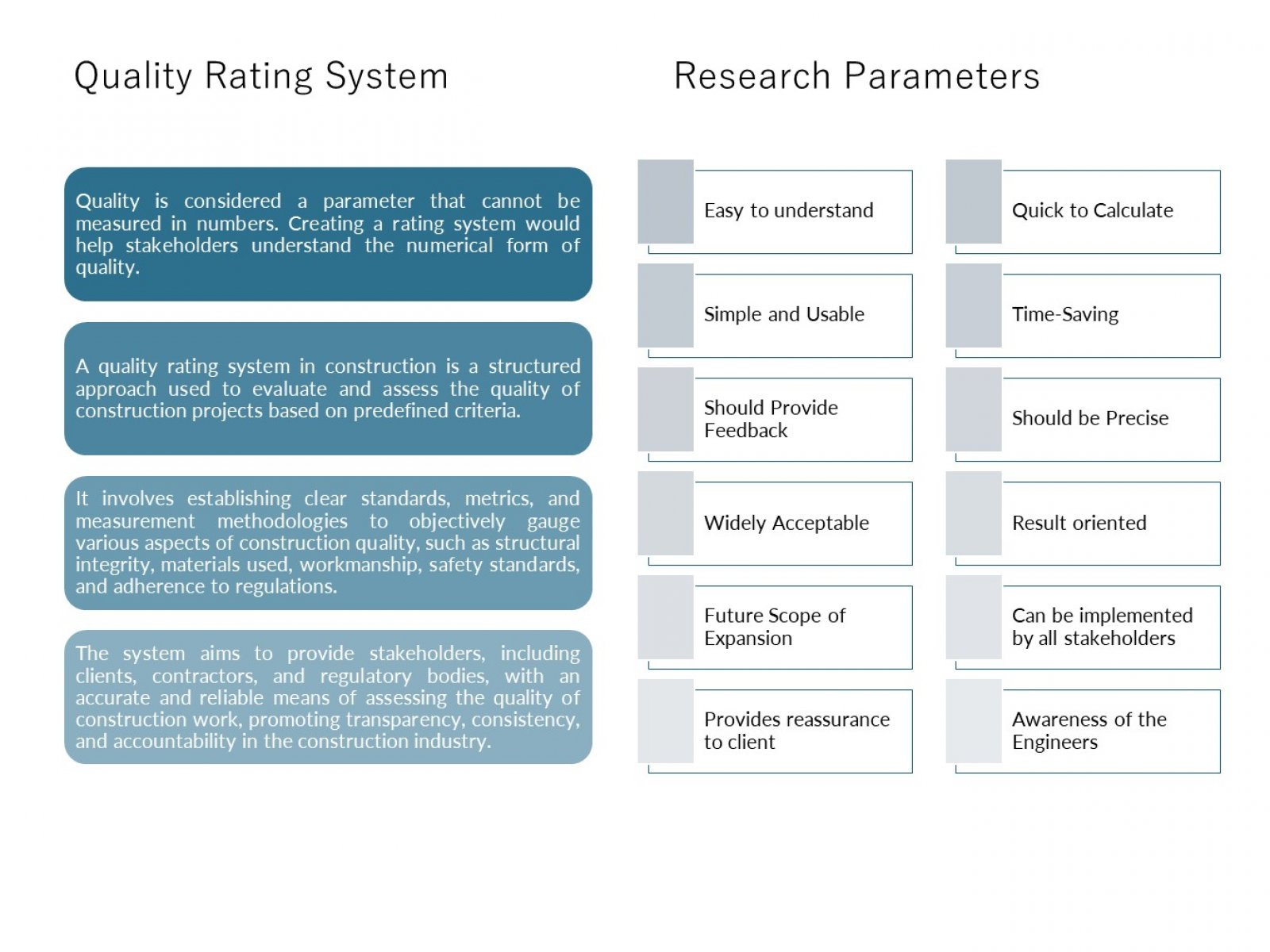

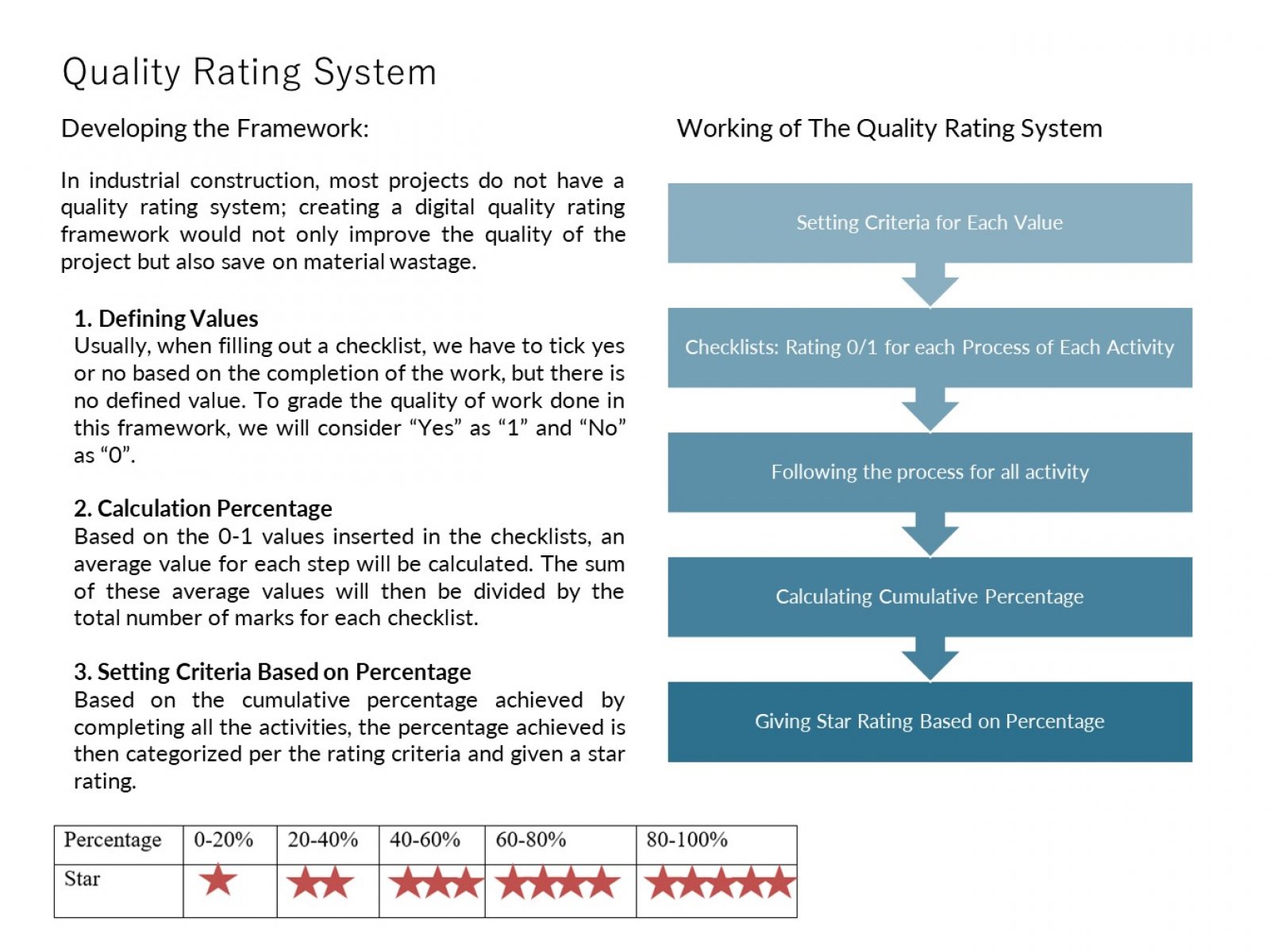

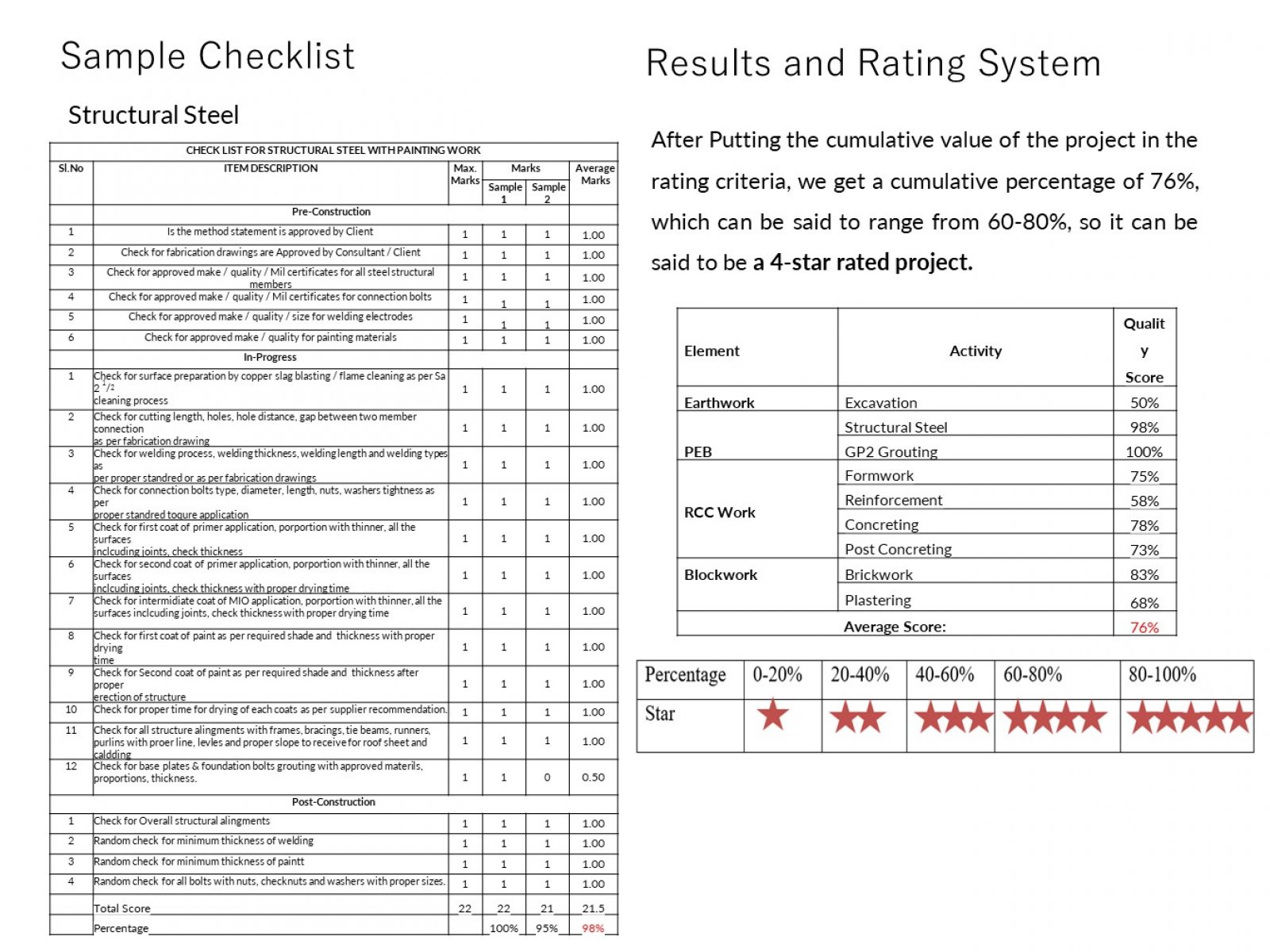

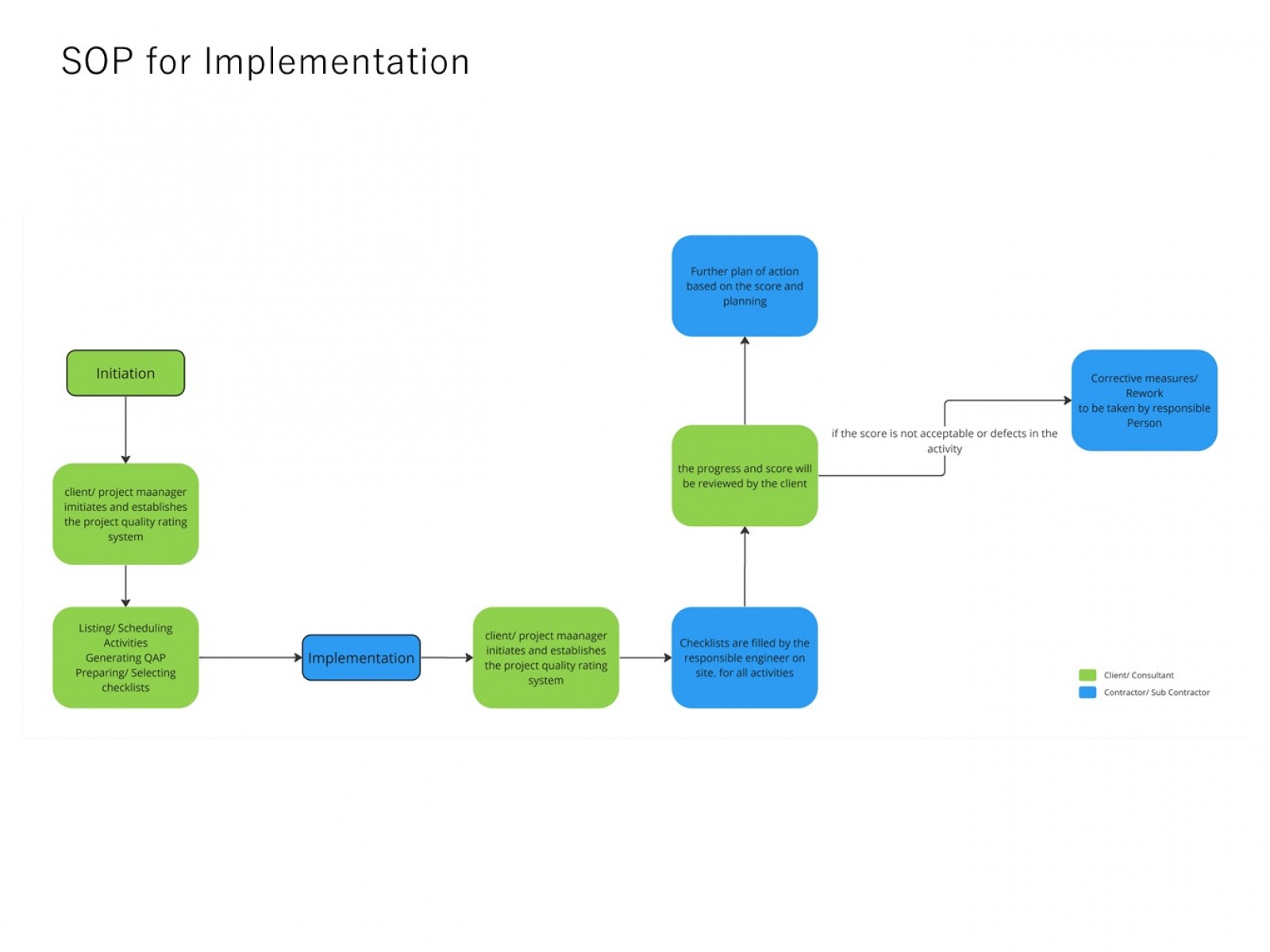

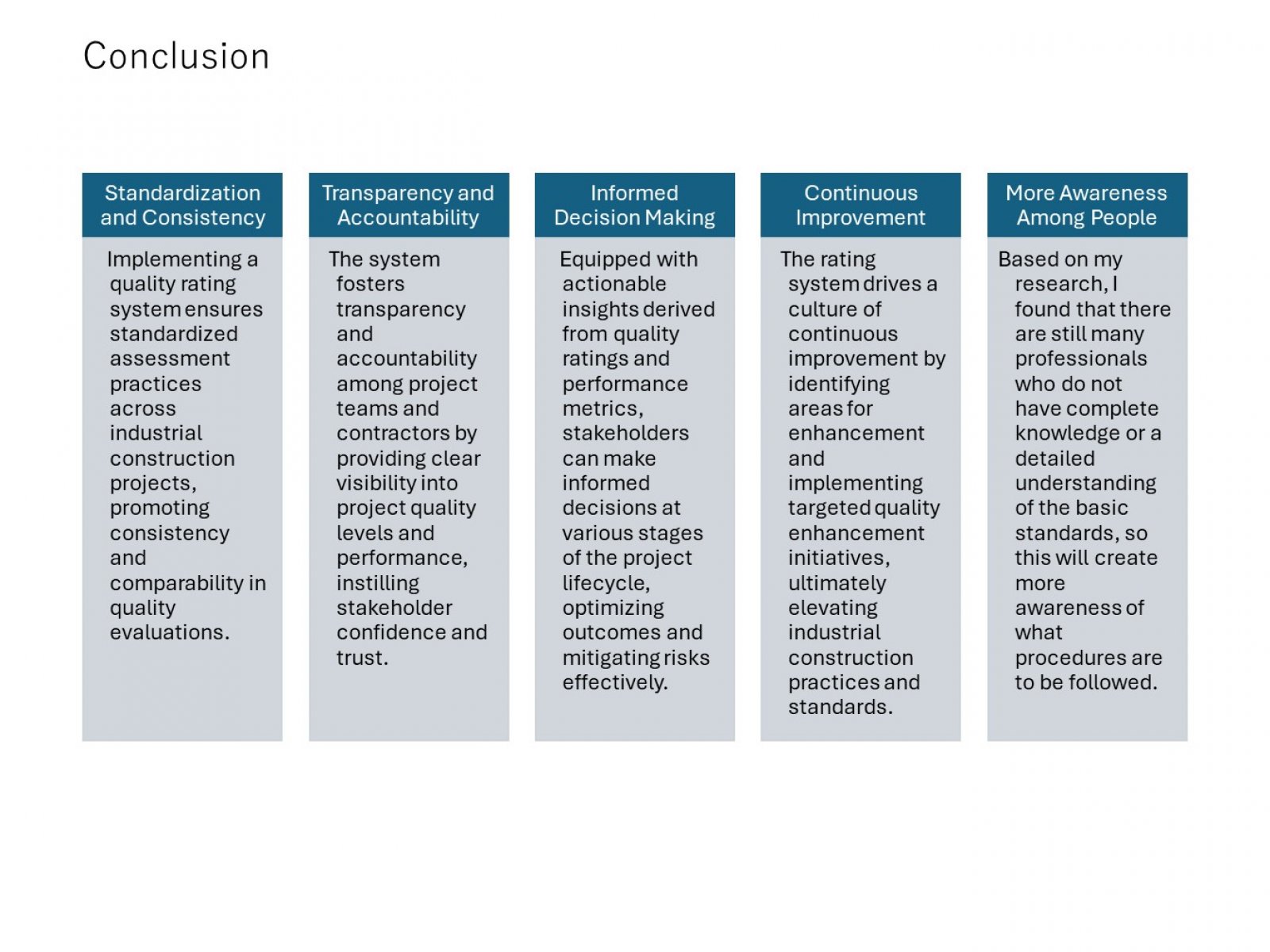

In India's rapidly growing landscape of industrial construction, ensuring project quality remains a critical challenge, particularly for small-scale industries constrained by budget limitations. With limited resources, these industries often struggle to afford dedicated quality personnel, leading to potential compromises in construction quality. In such cases, to ensure that the quality is not compromised, the digitization of Quality Assurance and Quality Control (QAQC) for obtaining authentic project quality ratings is important. QA and QC procedures help identify and rectify issues early; they contribute to cost efficiency, preventing costly rework and maintaining projects within budget. In this research, 10 case studies have been selected for data collection and understanding of quality control procedures, out of which five have a dedicated QAQC Framework and 5 do not have a dedicated framework. Studies have been conducted on how the quality of construction projects is ensured in industries with a dedicated quality control department and industries that do not have one. This study shows how these measures can be implemented in small-scale projects. Maintaining quality will be much easier for the clients and consultants using this digital framework. This will also help select contractors and Project Management Consultants for future reference. This framework empowers clients to make informed decisions by grading the stakeholders involved in the project. This helps save money and improves project quality outcomes that reduce delays in the project, cost overruns, and other issues.