Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

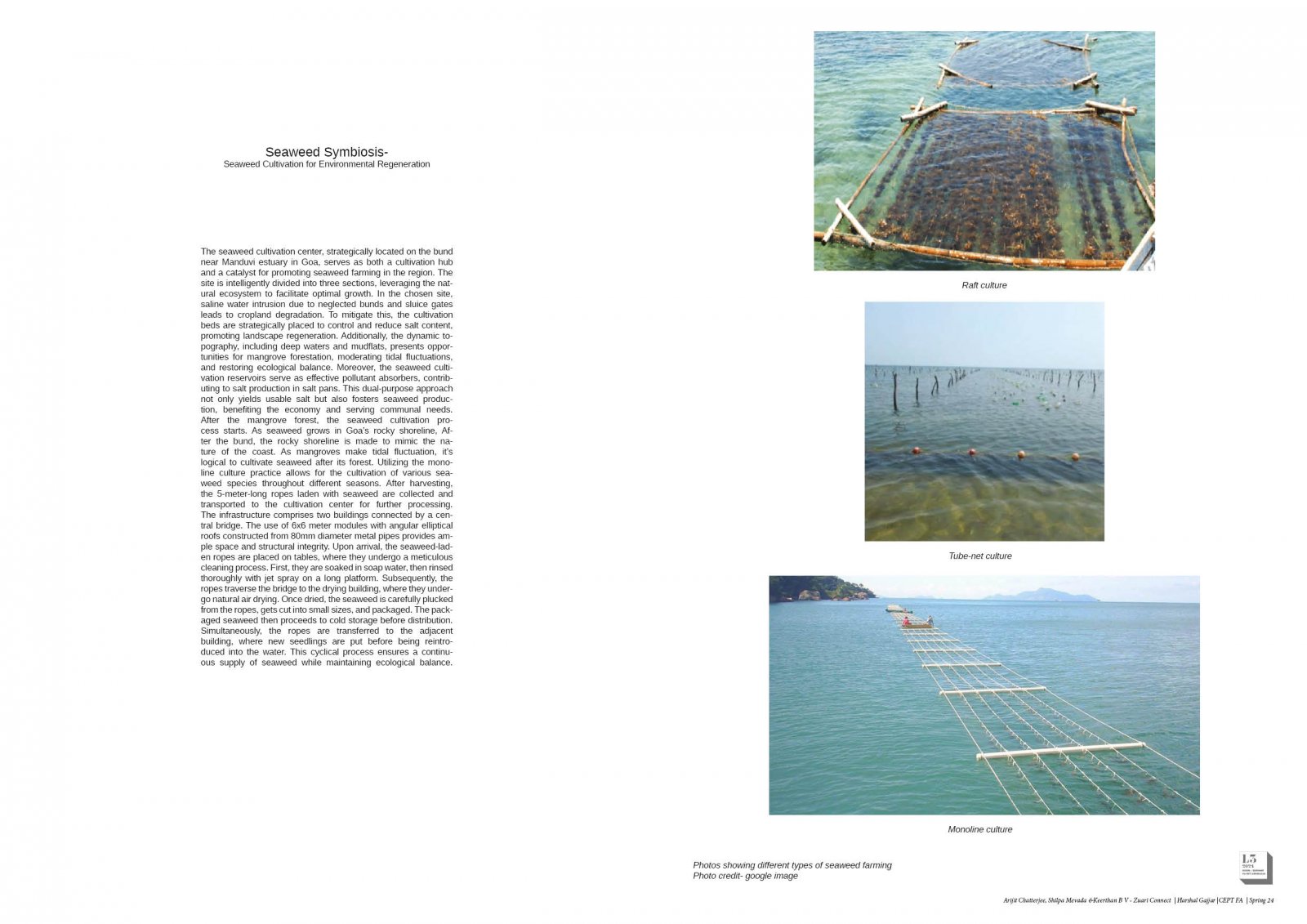

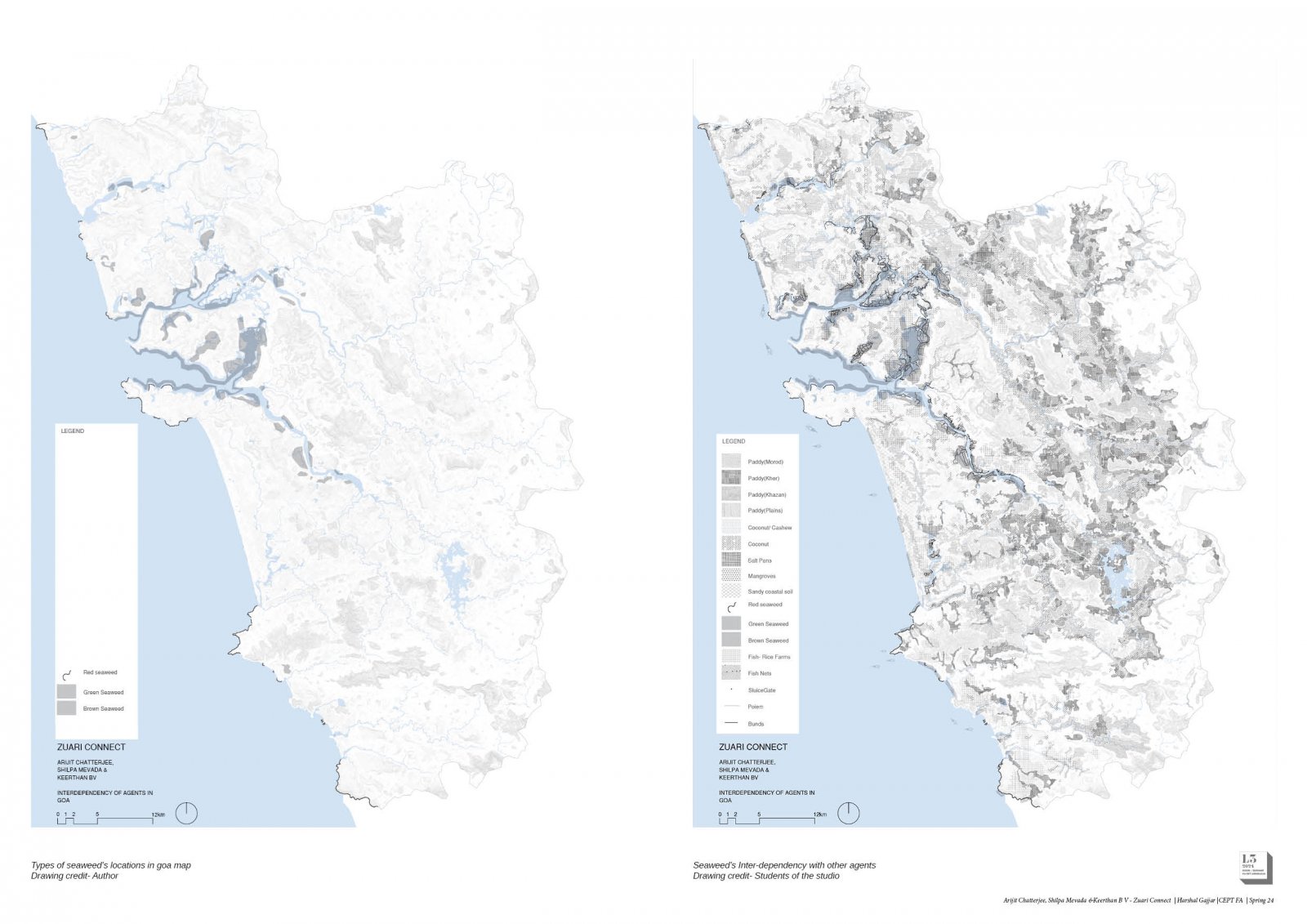

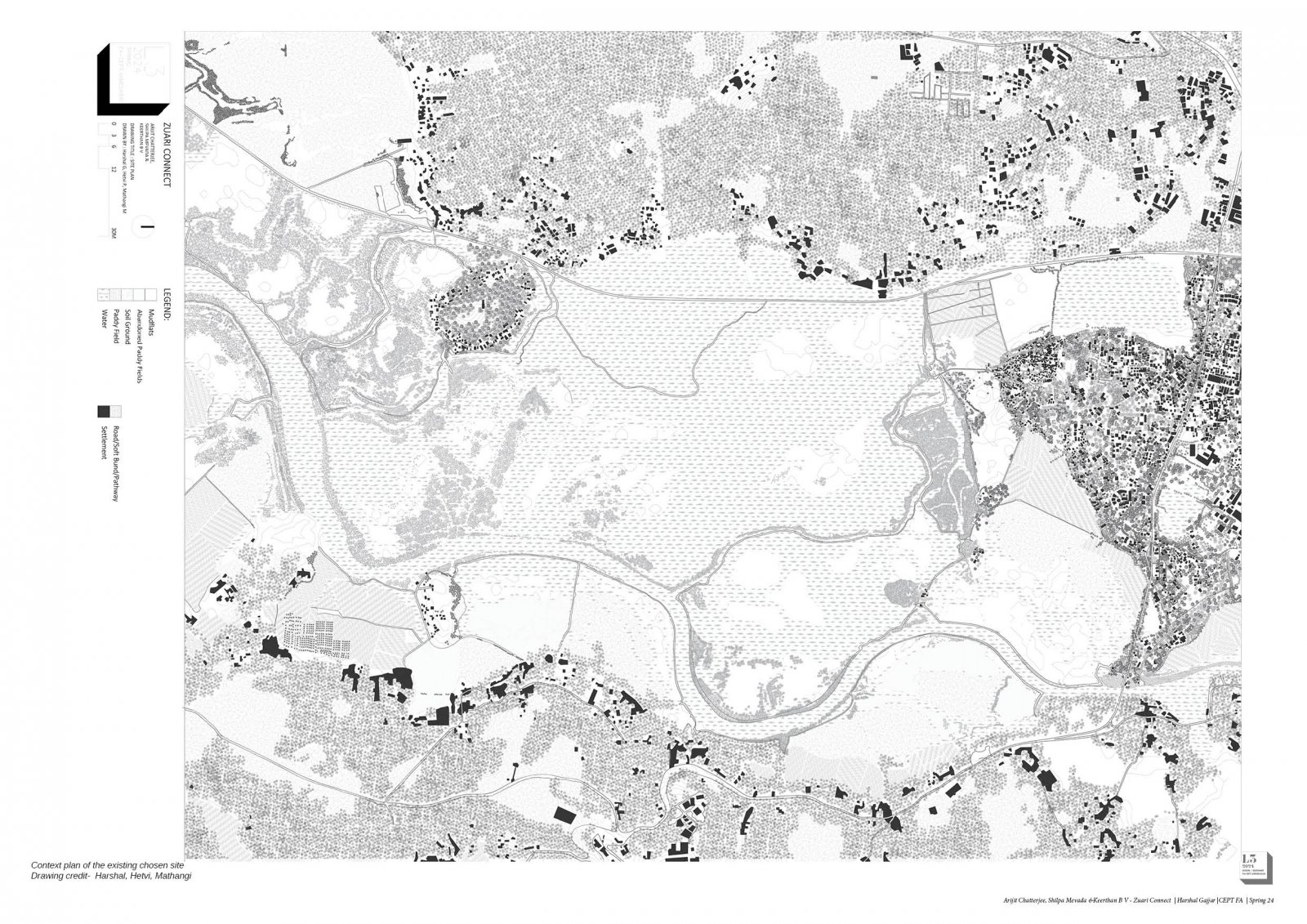

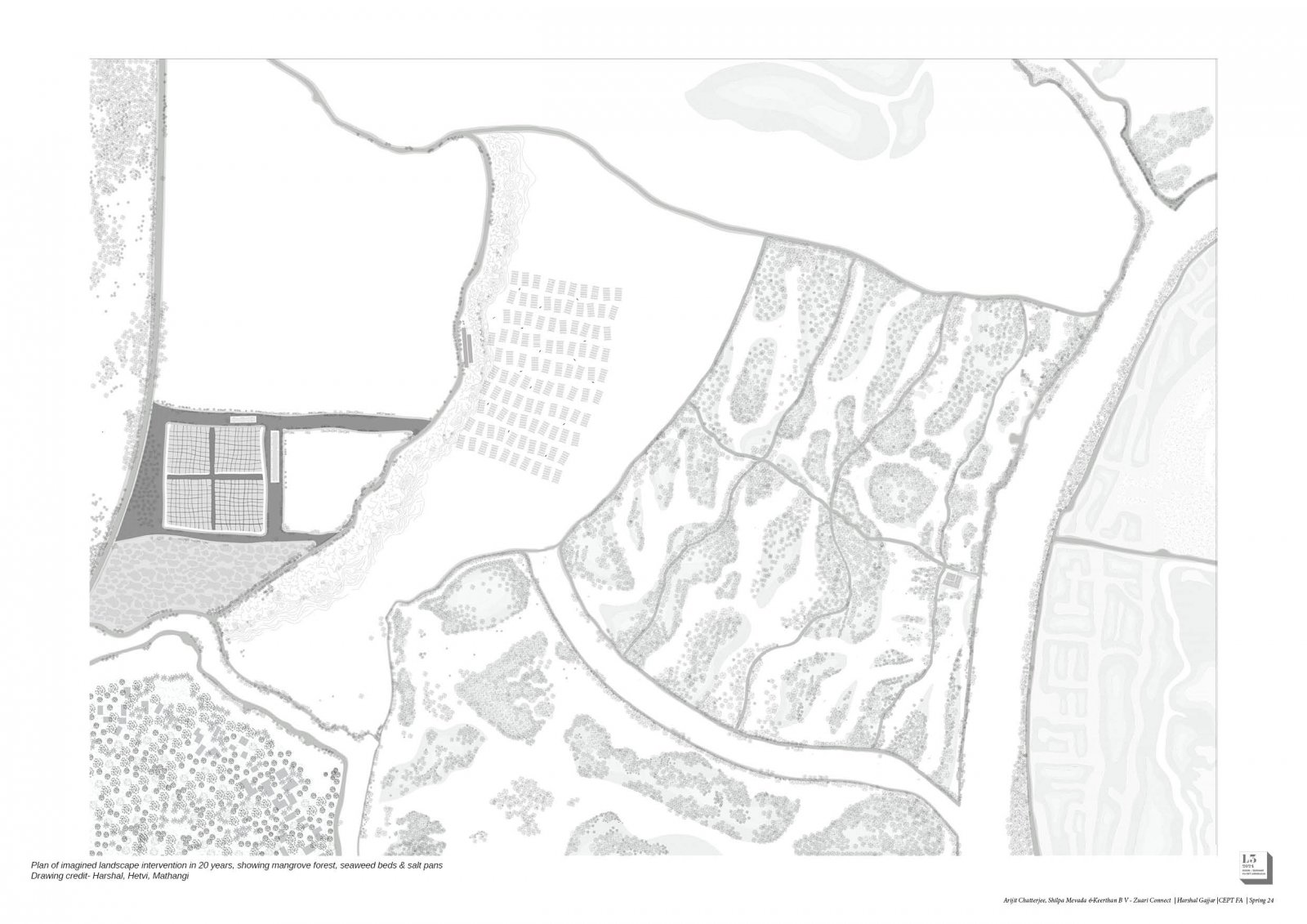

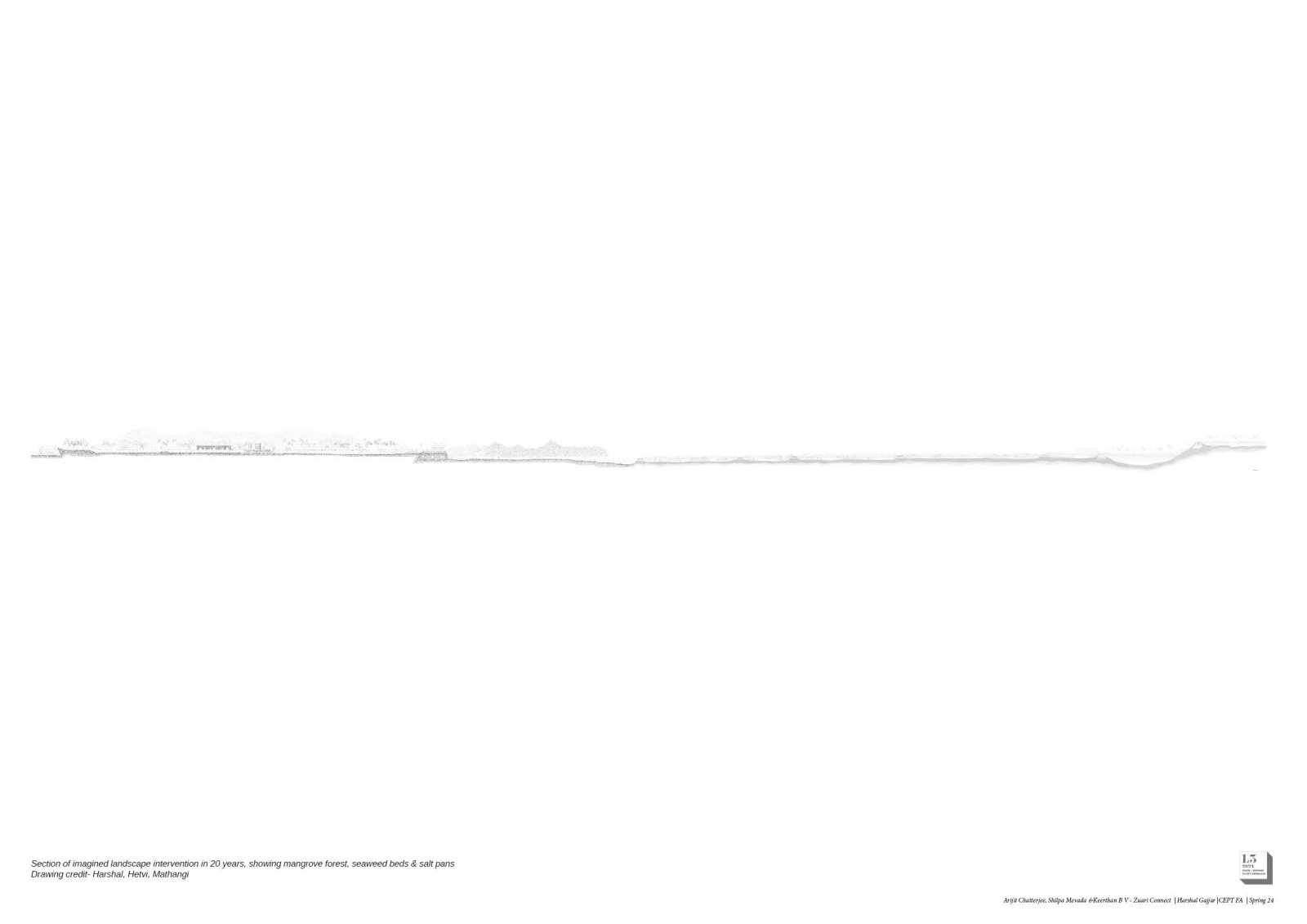

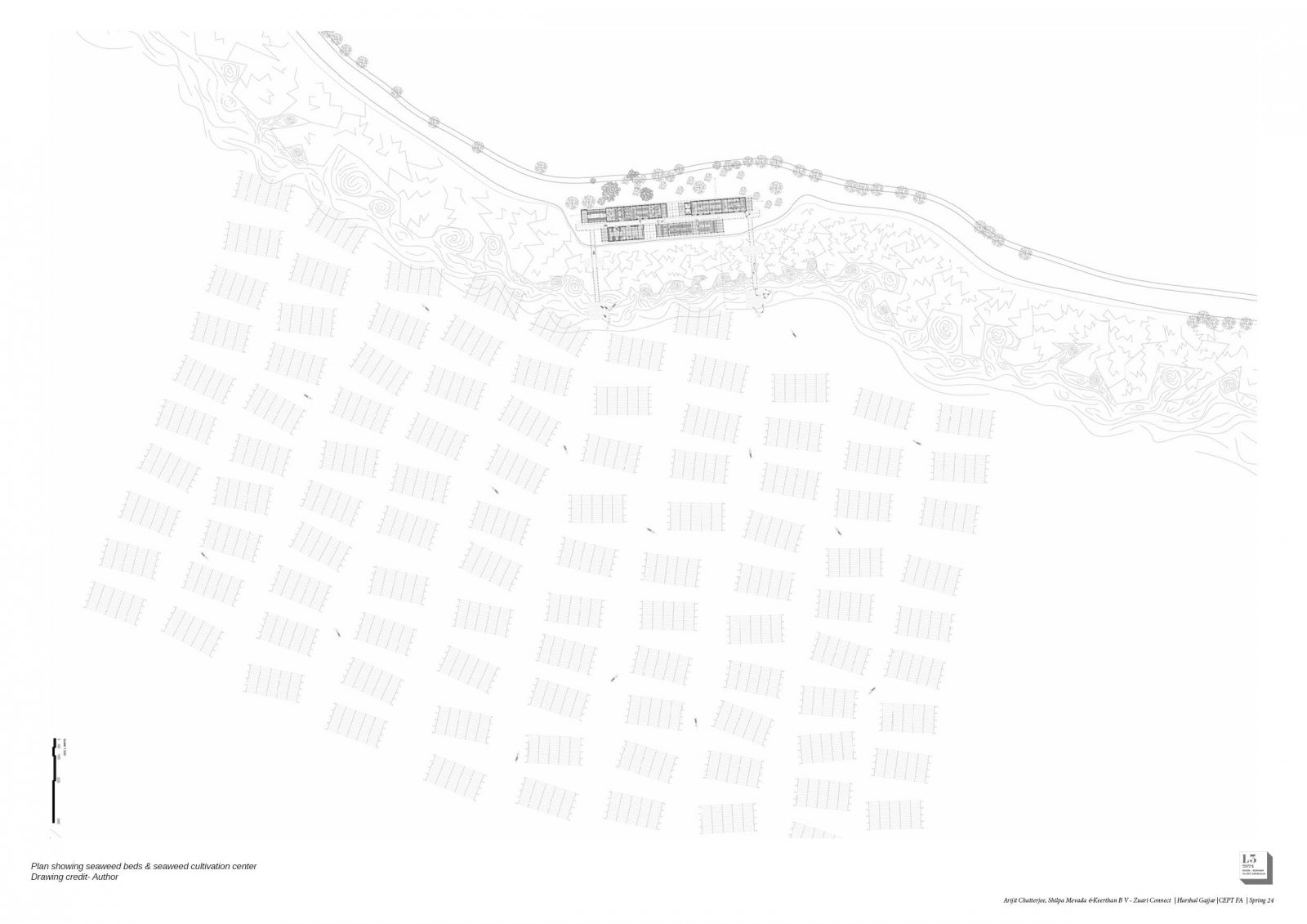

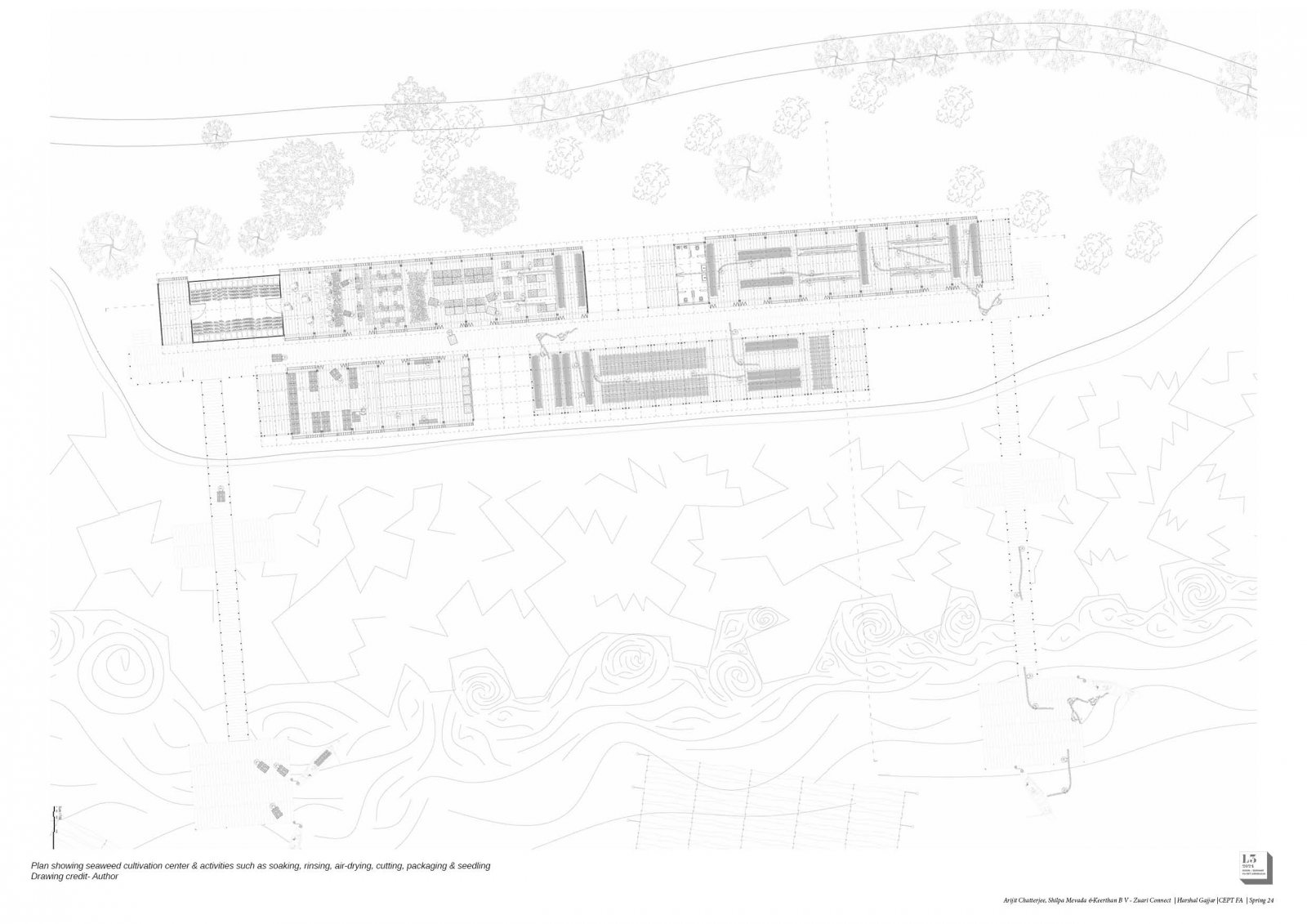

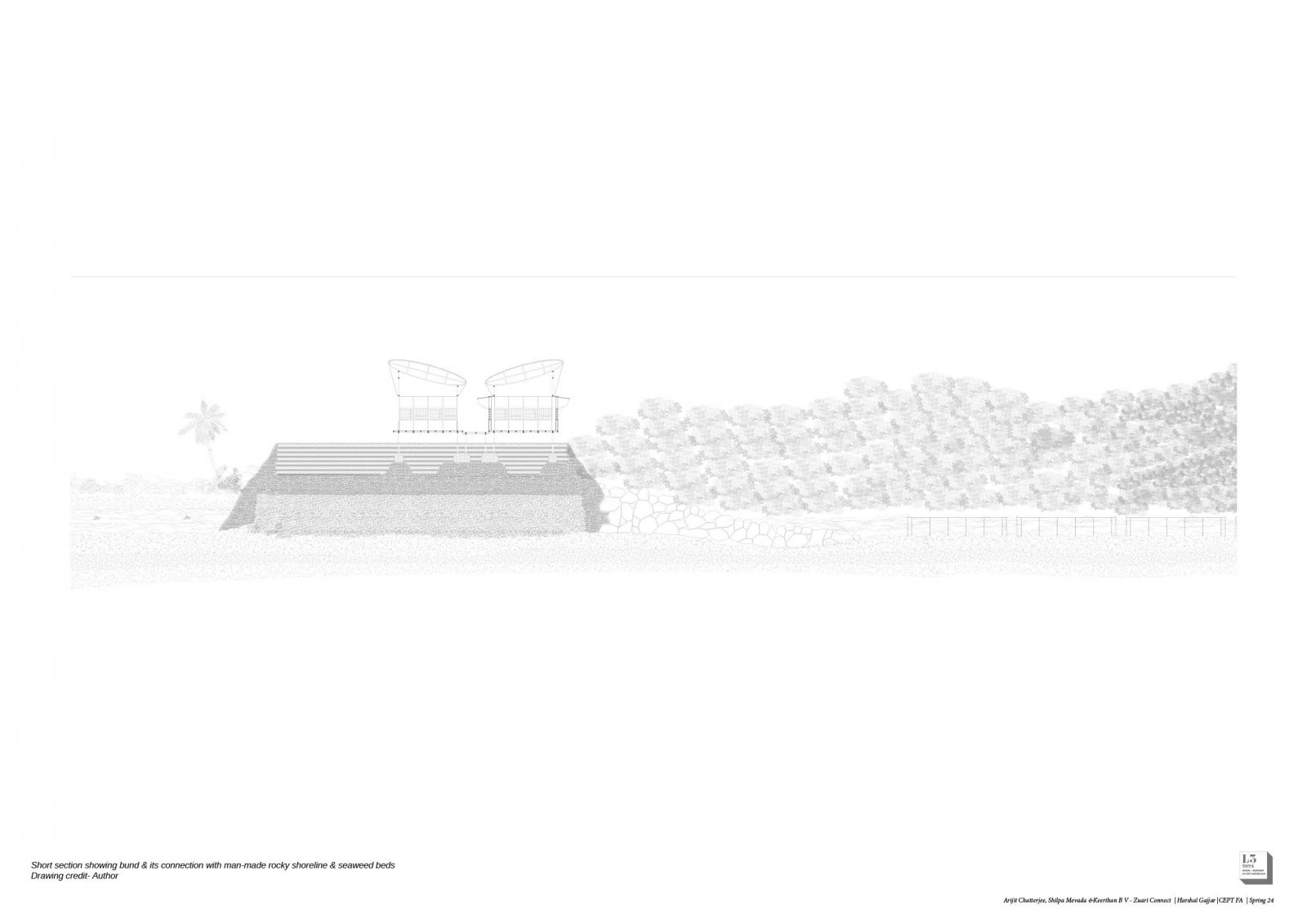

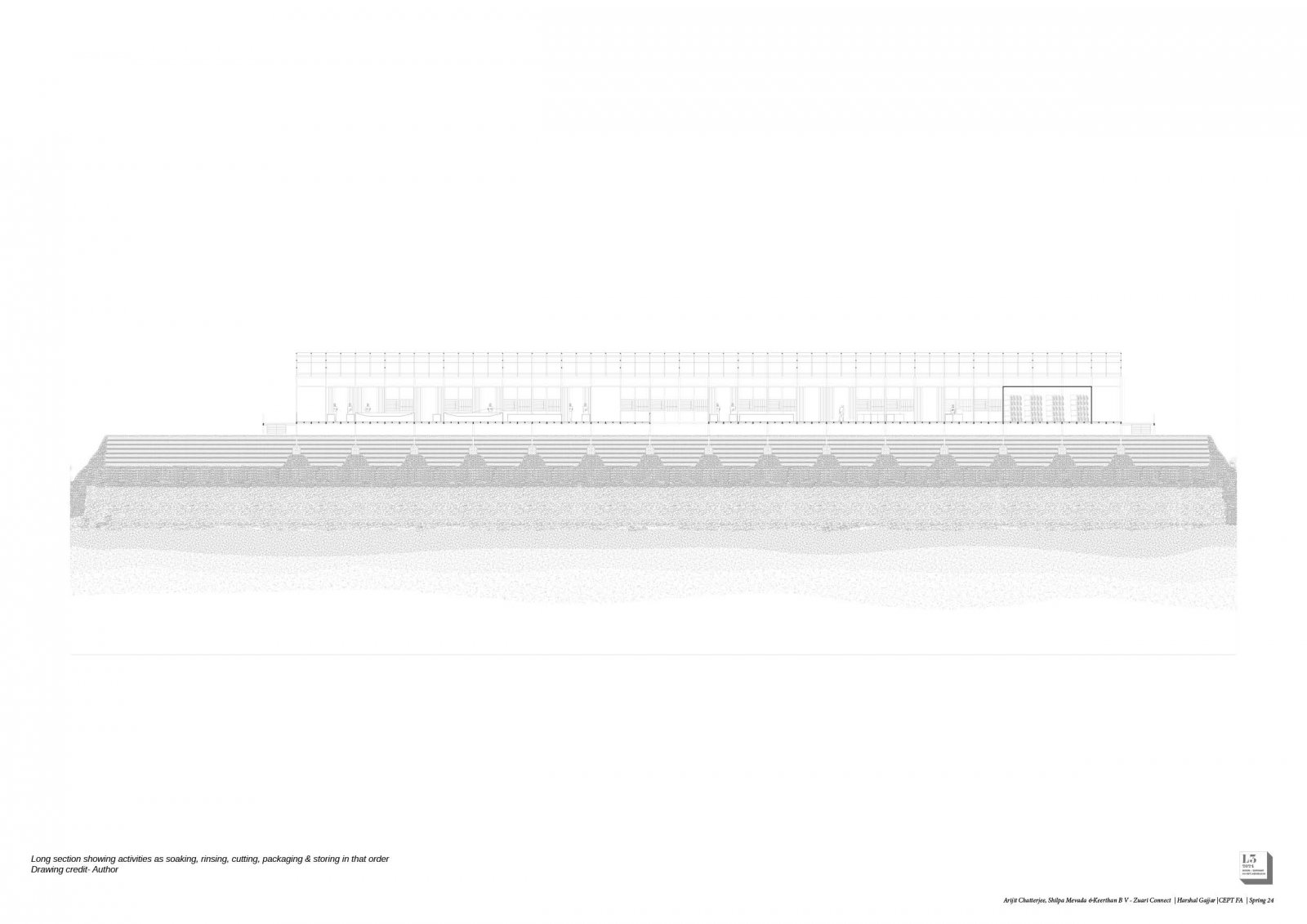

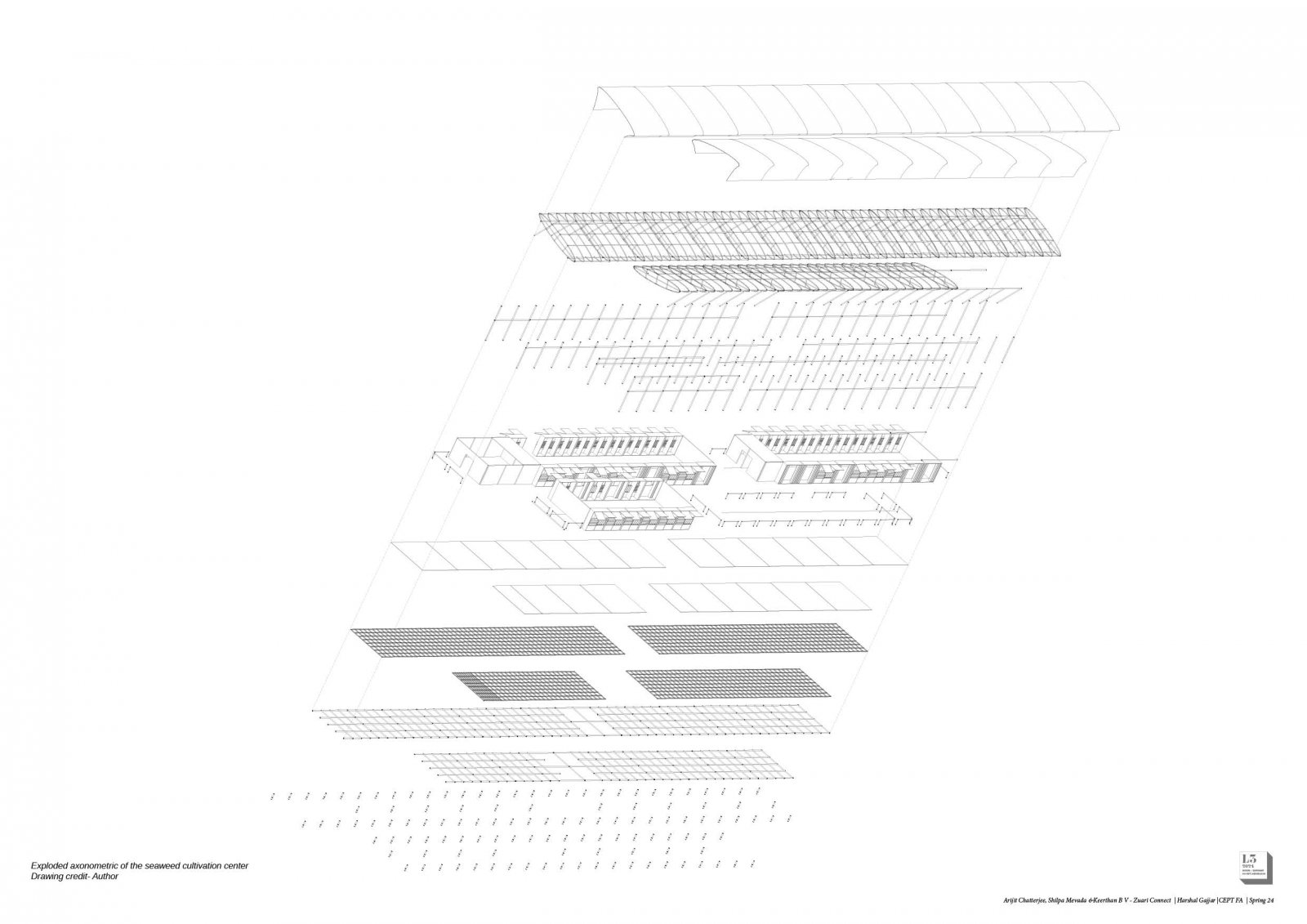

The seaweed cultivation center, strategically located on the bund near Manduvi estuary in Goa, serves as both a cultivation hub and a catalyst for promoting seaweed farming in the region. The site is intelligently divided into three sections, leveraging the natural ecosystem to facilitate optimal growth. In the chosen site, saline water intrusion due to neglected bunds and sluice gates leads to cropland degradation. To mitigate this, the cultivation beds are strategically placed to control and reduce salt content, promoting landscape regeneration. Additionally, the dynamic topography, including deep waters and mudflats, presents opportunities for mangrove forestation, moderating tidal fluctuations, and restoring ecological balance. Moreover, the seaweed cultivation reservoirs serve as effective pollutant absorbers, contributing to salt production in salt pans. This dual-purpose approach not only yields usable salt but also fosters seaweed production, benefiting the economy and serving communal needs. After the mangrove forest, the seaweed cultivation process starts. As seaweed grows in Goa’s rocky shoreline, After the bund, the rocky shoreline is made to mimic the nature of the coast. As mangroves make tidal fluctuation, it’s logical to cultivate seaweed after its forest. Utilizing the monoline culture practice allows for the cultivation of various seaweed species throughout different seasons. After harvesting, the 5-meter-long ropes laden with seaweed are collected and transported to the cultivation center for further processing. The infrastructure comprises two buildings connected by a central bridge. The use of 6x6 meter modules with angular elliptical roofs constructed from 80mm diameter metal pipes provides ample space and structural integrity. Upon arrival, the seaweed-laden ropes are placed on tables, where they undergo a meticulous cleaning process. First, they are soaked in soap water, then rinsed thoroughly with jet spray on a long platform. Subsequently, the ropes traverse the bridge to the drying building, where they undergo natural air drying. Once dried, the seaweed is carefully plucked from the ropes, cut into small sizes, and packaged. The packaged seaweed then proceeds to cold storage before distribution. Simultaneously, the ropes are transferred to the adjacent building, where new seedlings are put before being reintroduced into the water. This cyclical process ensures a continuous supply of seaweed while maintaining ecological balance.