Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

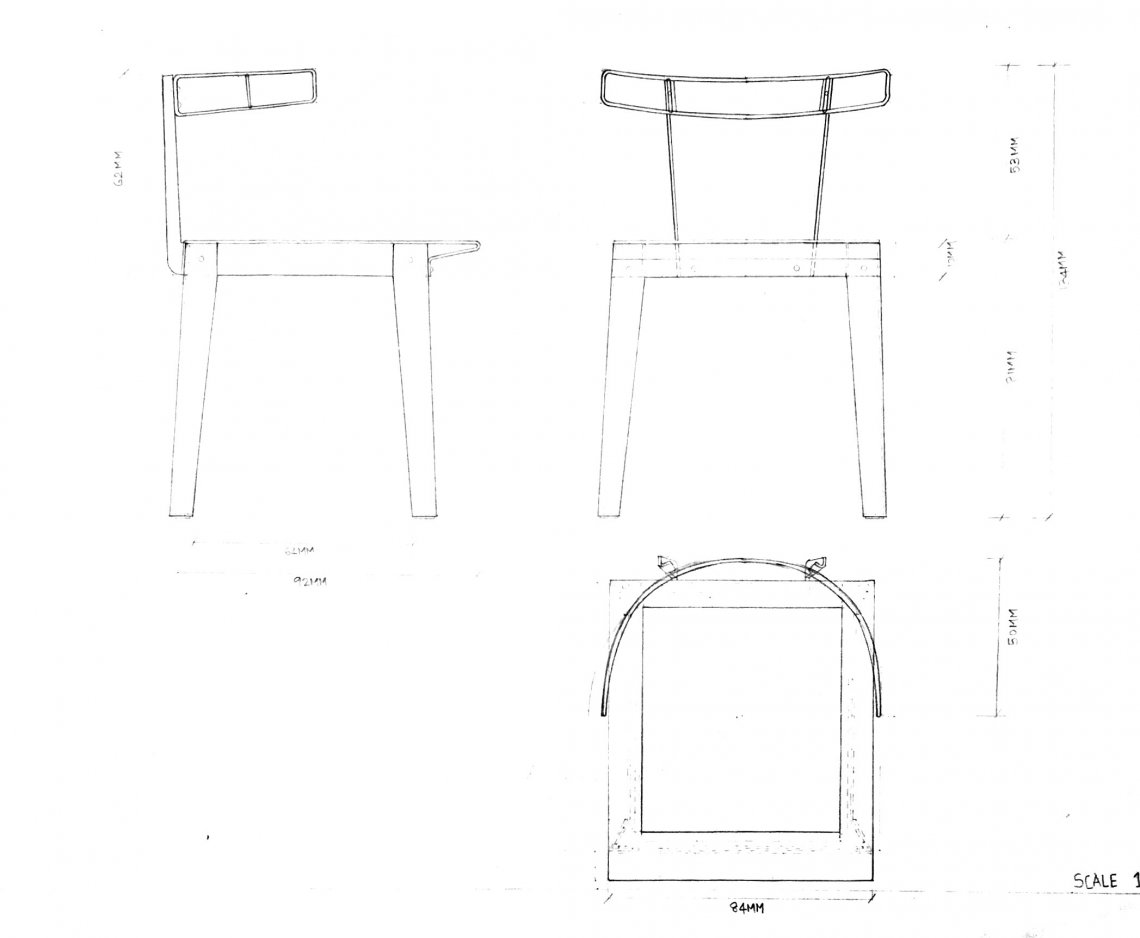

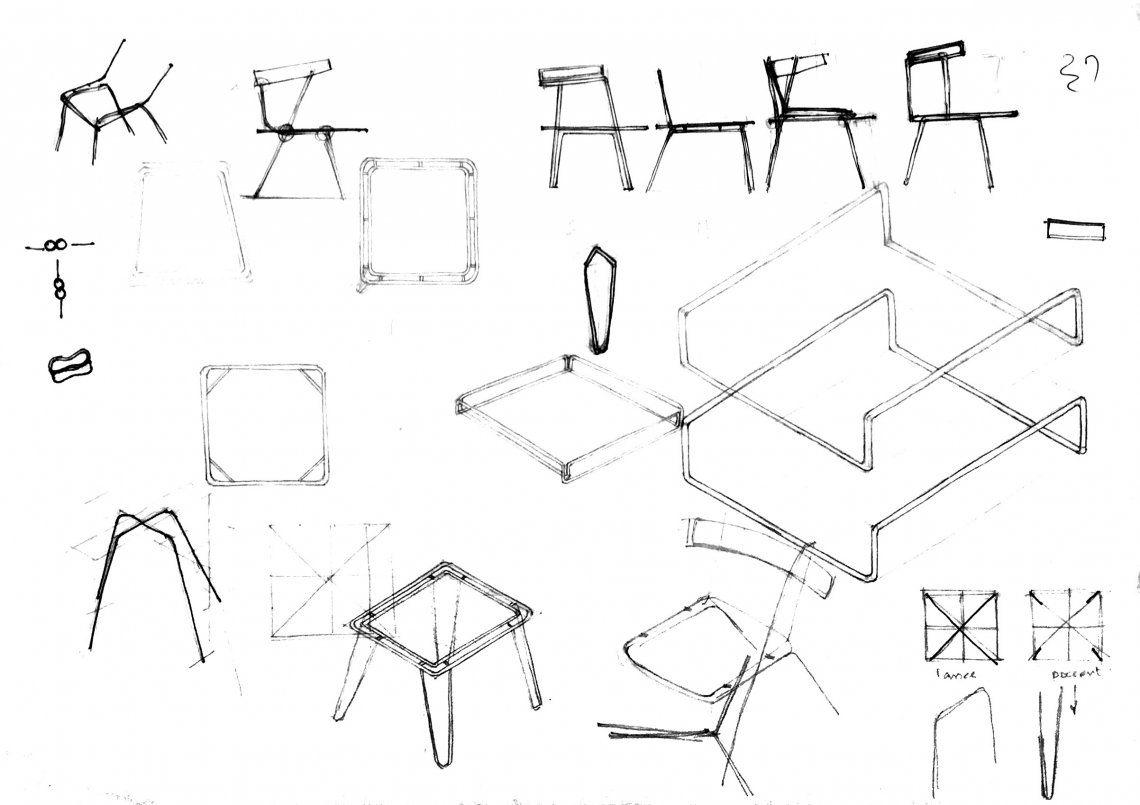

The basic structure is developed following the principle of SIMPLY SUPPORTED, as there is certain geometry which is followed while developing the form i.e. the angles the components are bent. The structure is developed using sheet metal. Each material has a different load capacity and reacts differently to the application of force, out of various possible and provided properties of metal SHEET METAL BENDING provides both tension and compression within the material.With subject to load because of the bent the load would be transfered on multiple points of single component where surface area would be increased which is appropriate to hold and carry load. There are few critical junctions i.e. seat-leg and backrest-leg, as mentioned the surface area at these points are increased to avoid any deformation as those are the junctions where different members comes in contact with each other and load is been transfered. Taking backrest into consideration there would be immense force acting while the structure is in use hence the back legs are designed in a way that backrest would rest on that back legs provided enough support and stability is provided by the angle and the weight of the sheet metal back rest is supported. Taking continous members for supporting backrest adds on to the advantage of resisting forces on seat and backrest as there is continous flow of forces acting on whole component and getting transfered rather than dividing components leading to dividing the way to transfer the load which has tendency to break the flow of transformation of load which would also avoid buckling and wobbling of members at different junction. To provide necessary strength to seat the seat is being bent from outer edges and from inner edges which would also add on to extra support to weaving. Hence the bending of sheet metal Limits the elasticity of the material.The edges are defined using radius to avoid any kind of injury to the user and add on the the flow of vision through compontents of the structure developed. The juntions are developed in a way that no joineries are exposed to the outer form of the structure. Taking cost and economy into consideration sheet metal bending provides the same or more strength compared to the chunk of metal which is used to achieve form needs to carve out or deform and form using certain process which would add on the the cost so here the demanded strength is achieved by bending sheet metal which doesn’t by minimum operation which would cut down to the cost.The appearance is derived using the angles, curves and fillets at different junction which makes structure much more lighter.