Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

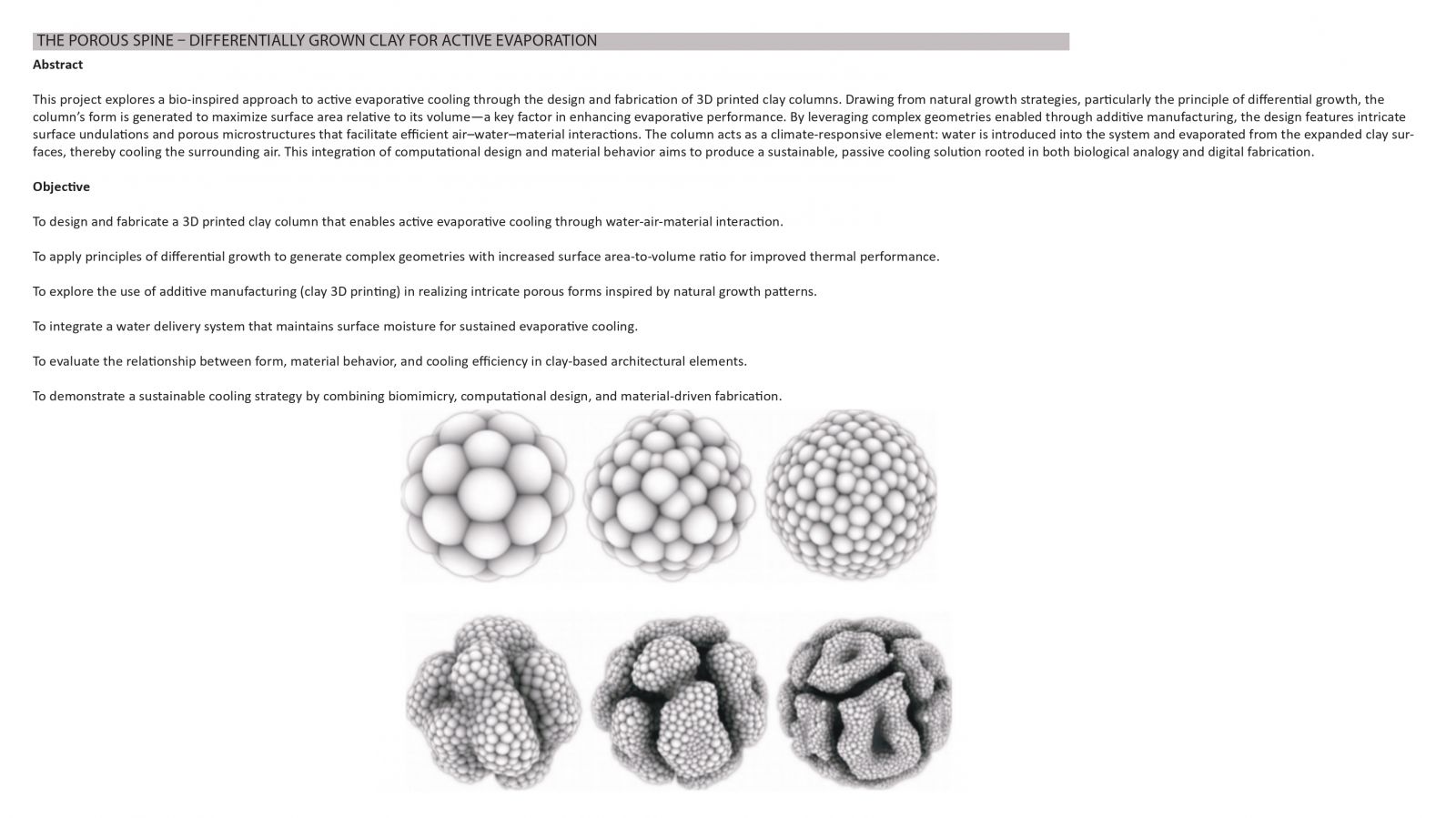

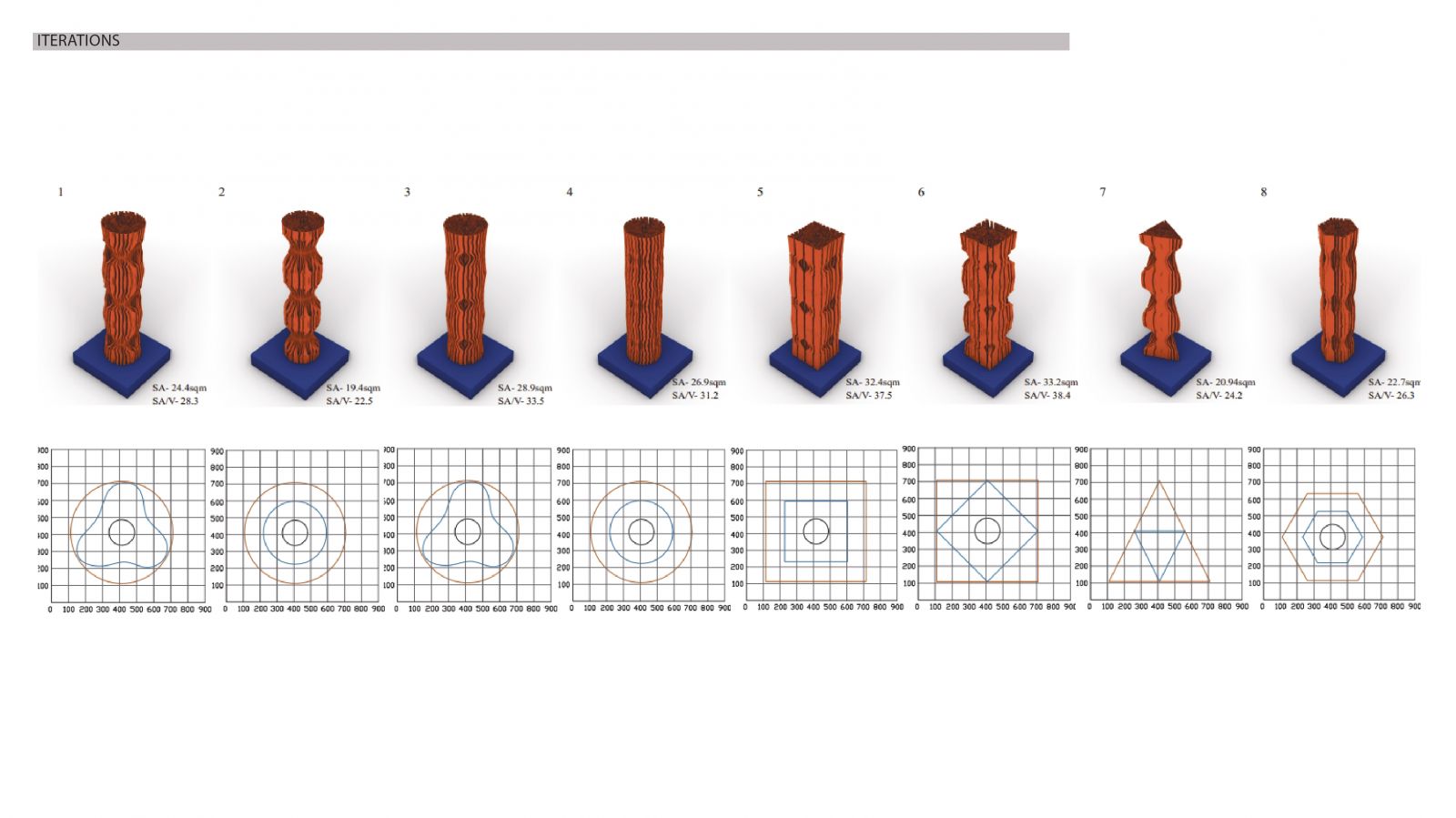

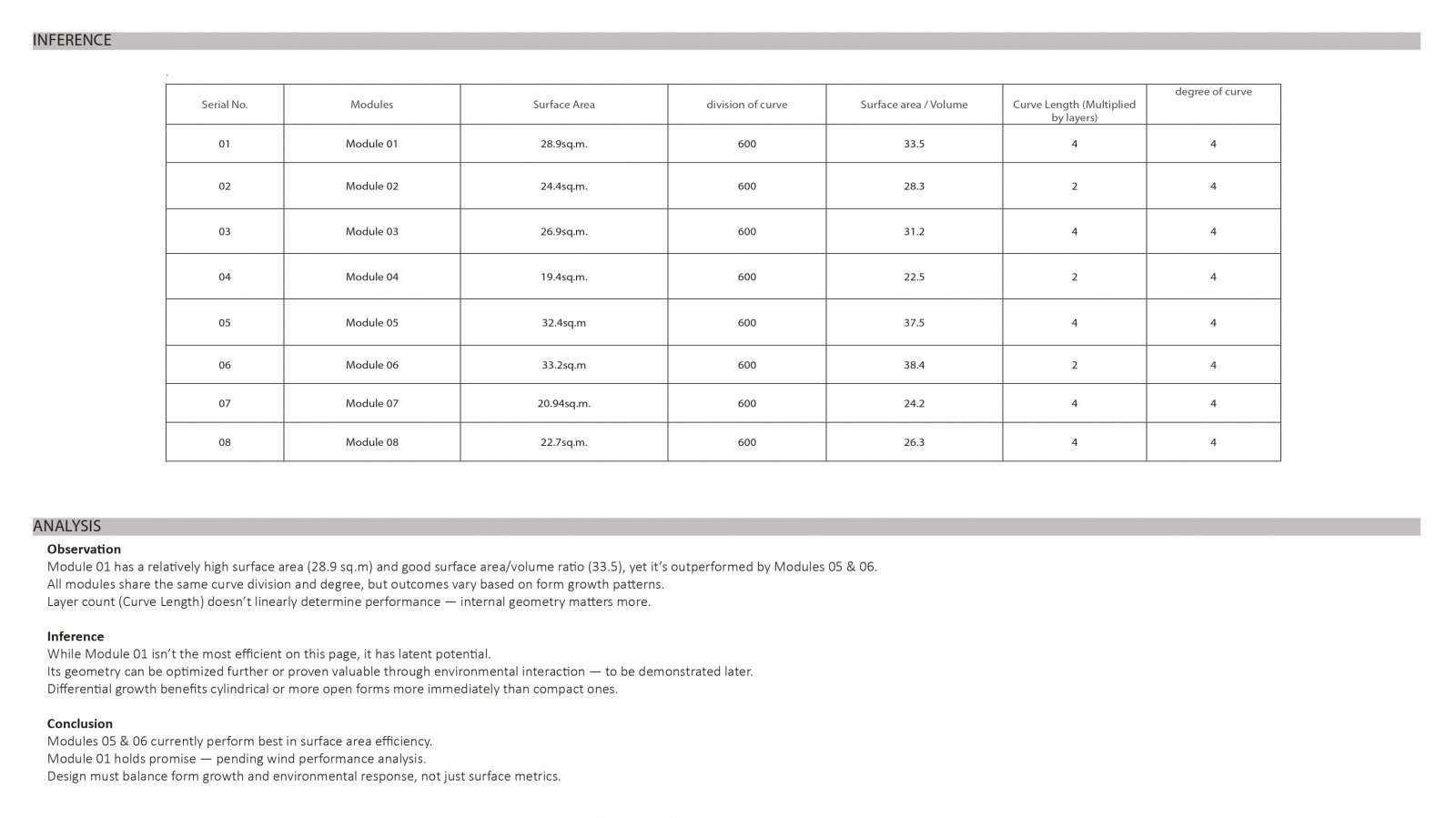

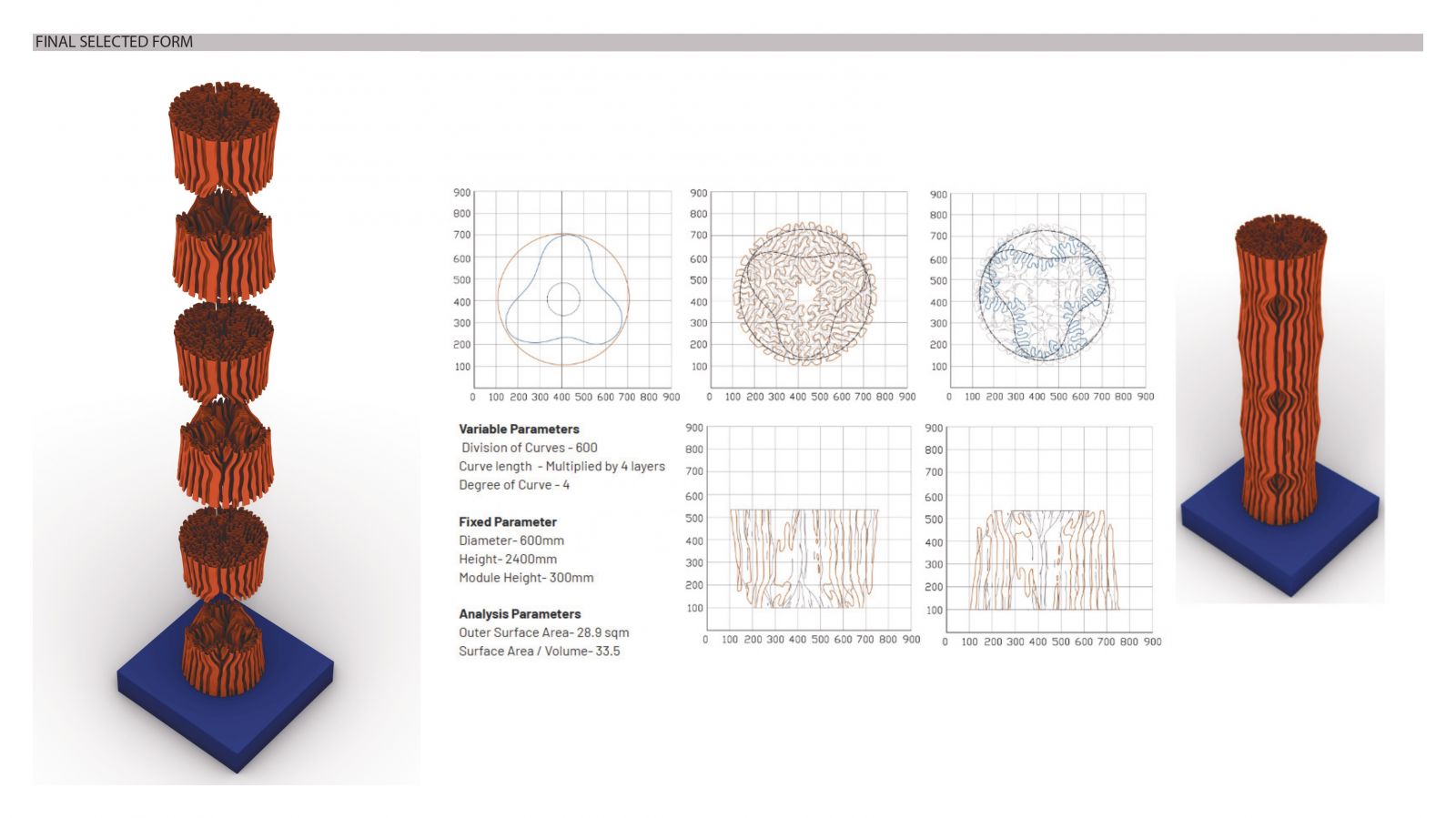

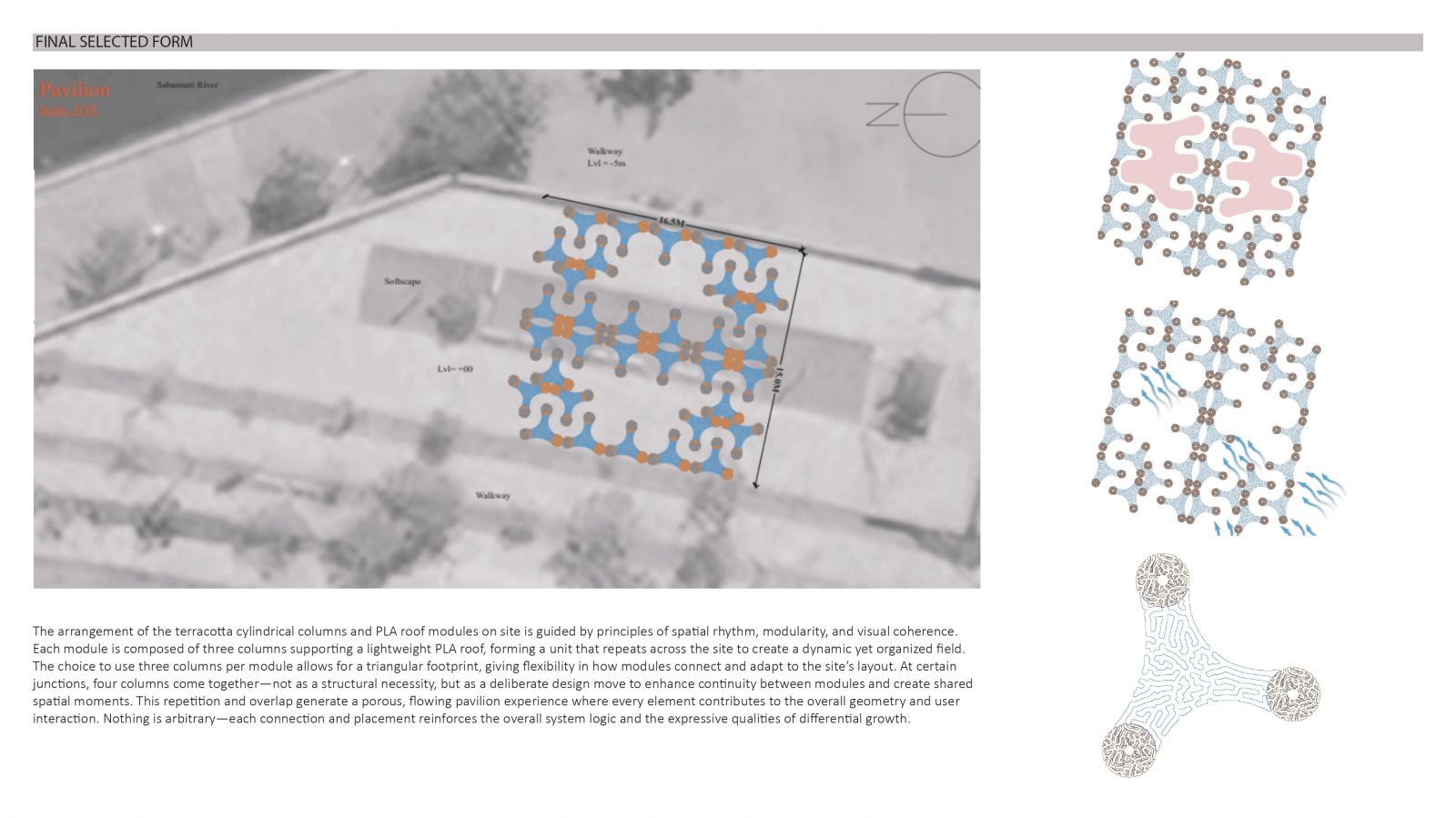

This project explores a modular pavilion system integrating terracotta cylindrical columns and lightweight PLA roof components. The design emphasizes spatial rhythm, modularity, and visual coherence, using a repeated unit composed of three columns and a triangular PLA roof module. These modules connect flexibly across the site, forming a dynamic yet structured layout. Occasionally, four-column intersections are introduced—not for structural support, but to enhance spatial continuity and shared moments. The overall configuration fosters a porous and flowing experience, guided by principles of differential growth, where each element and connection contributes meaningfully to the expressive and systemic logic of the pavilion.