Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

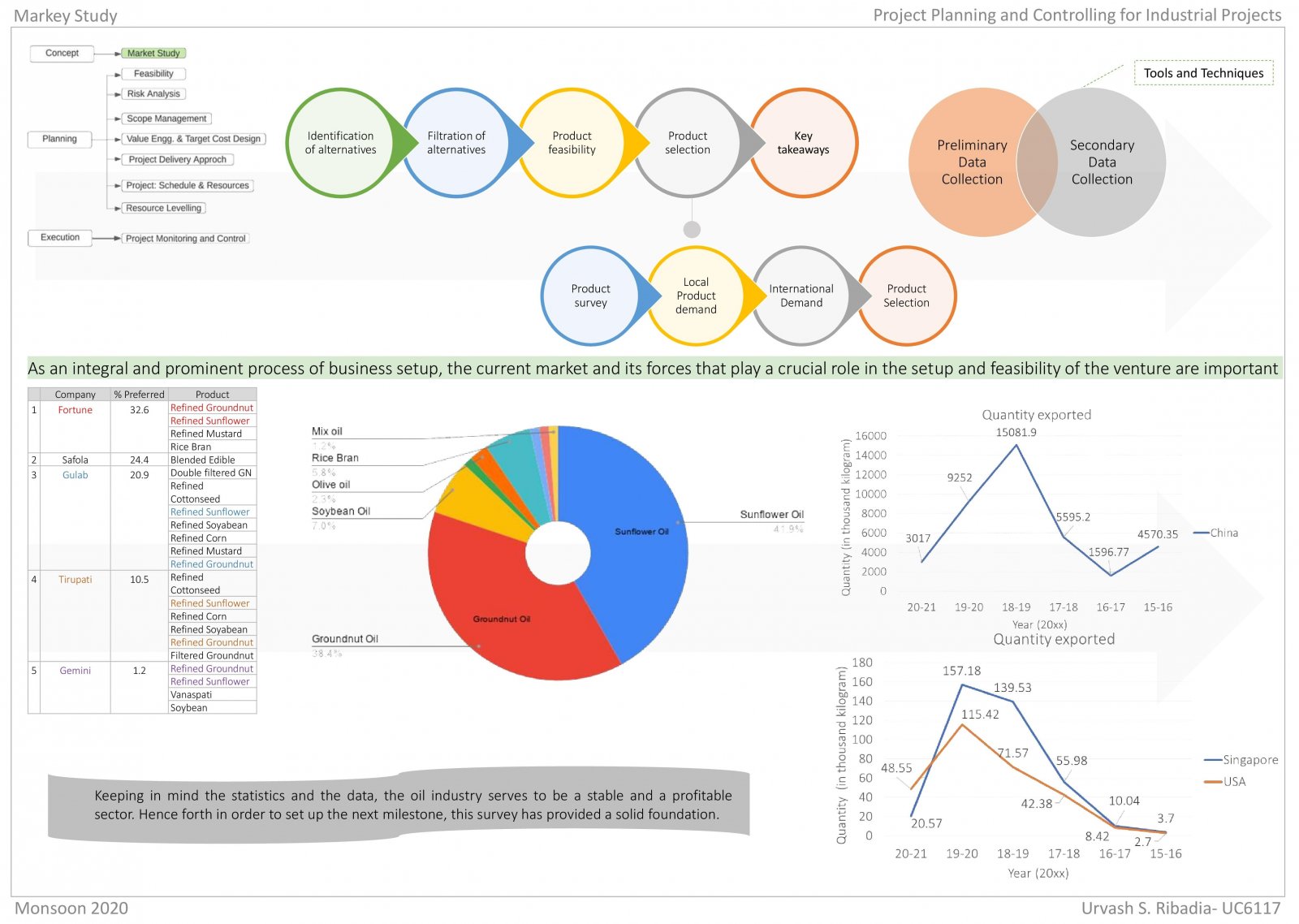

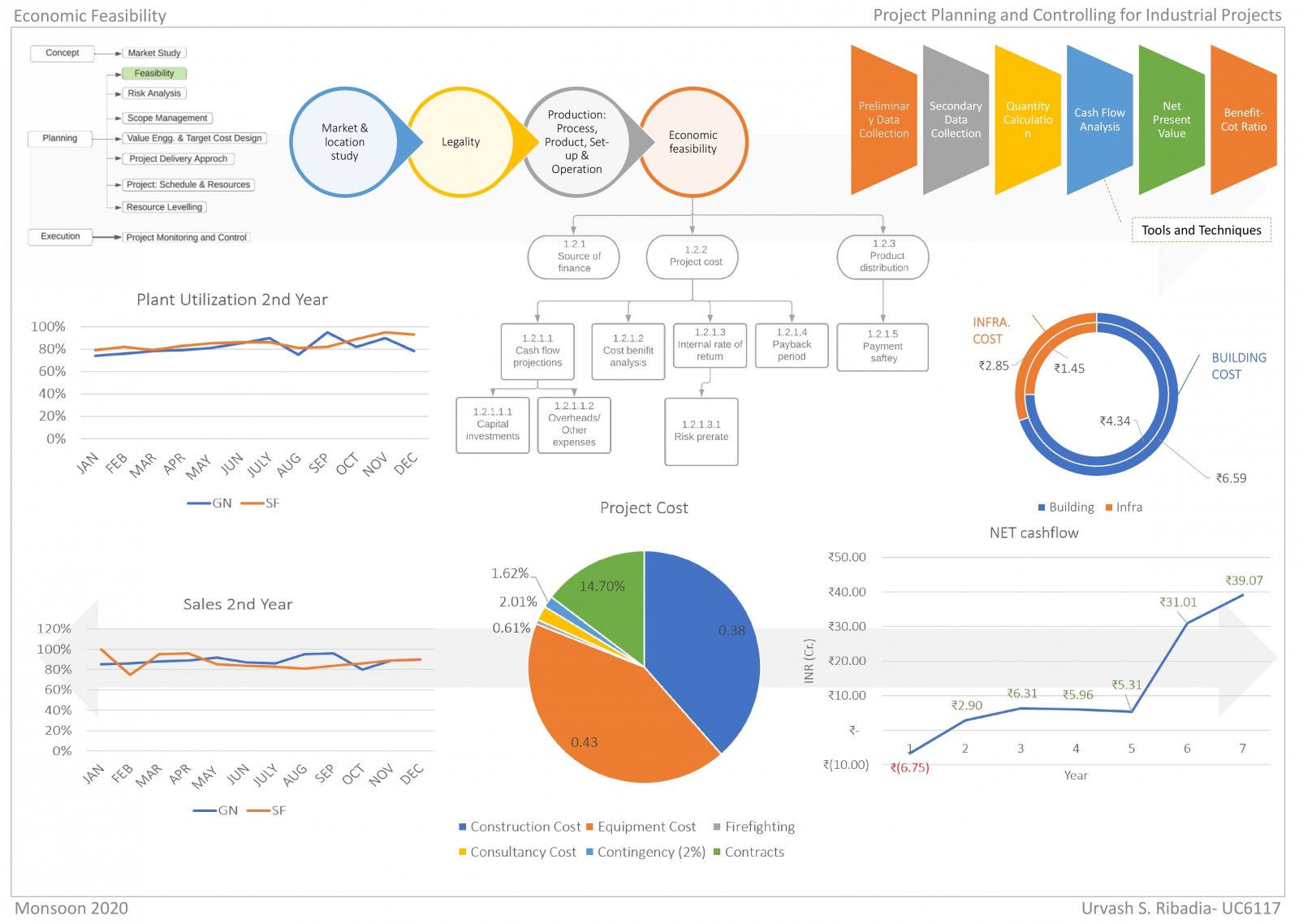

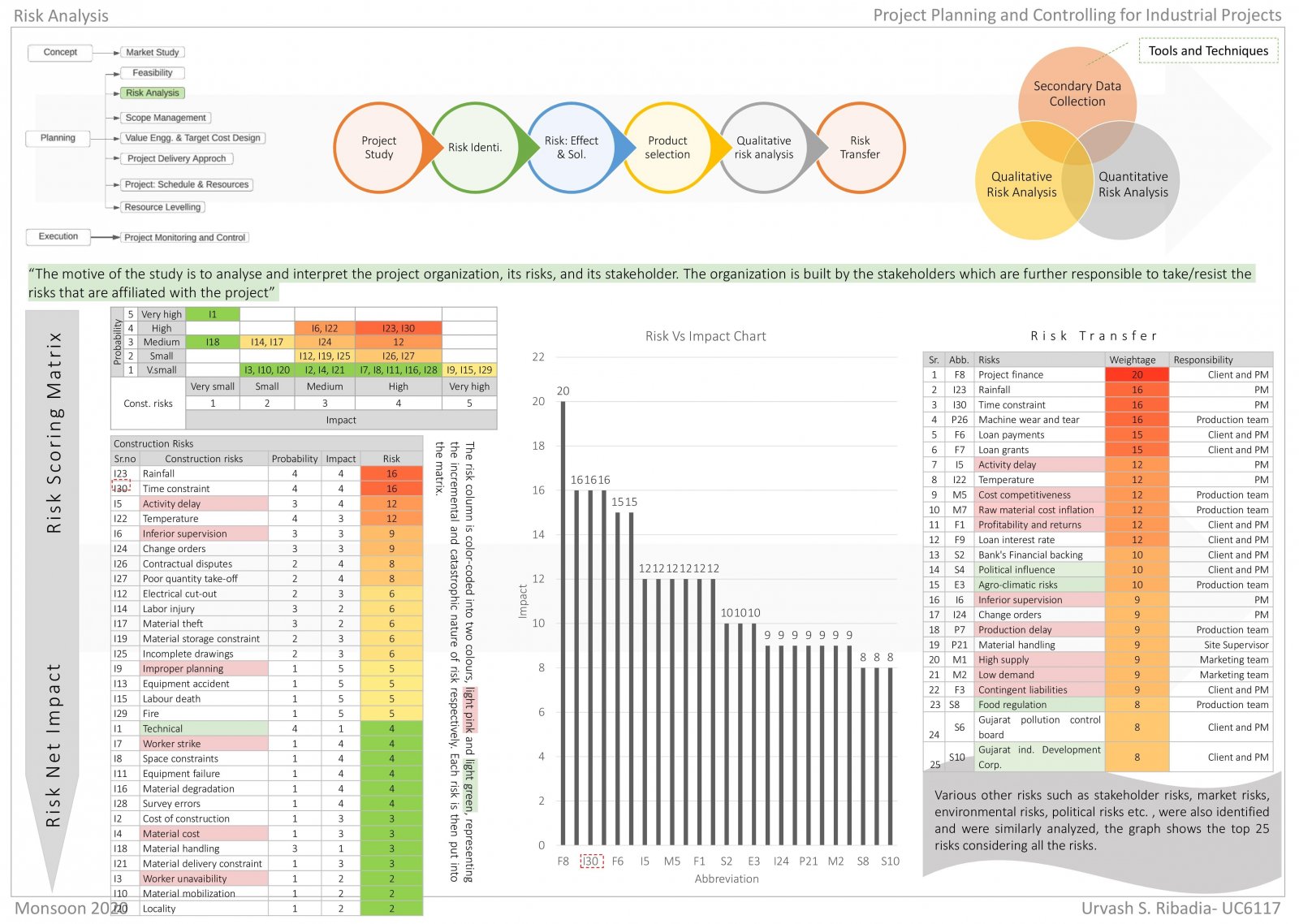

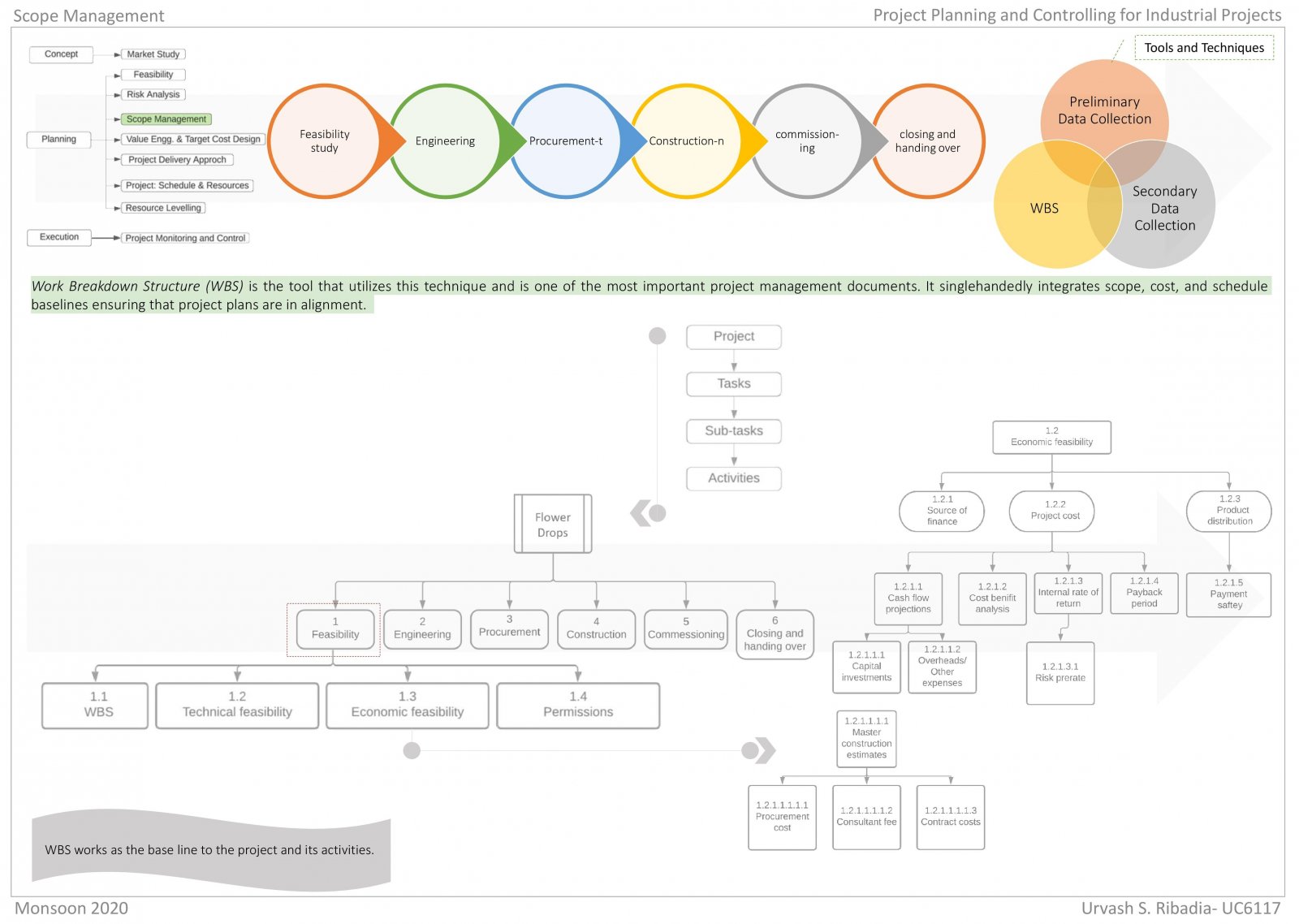

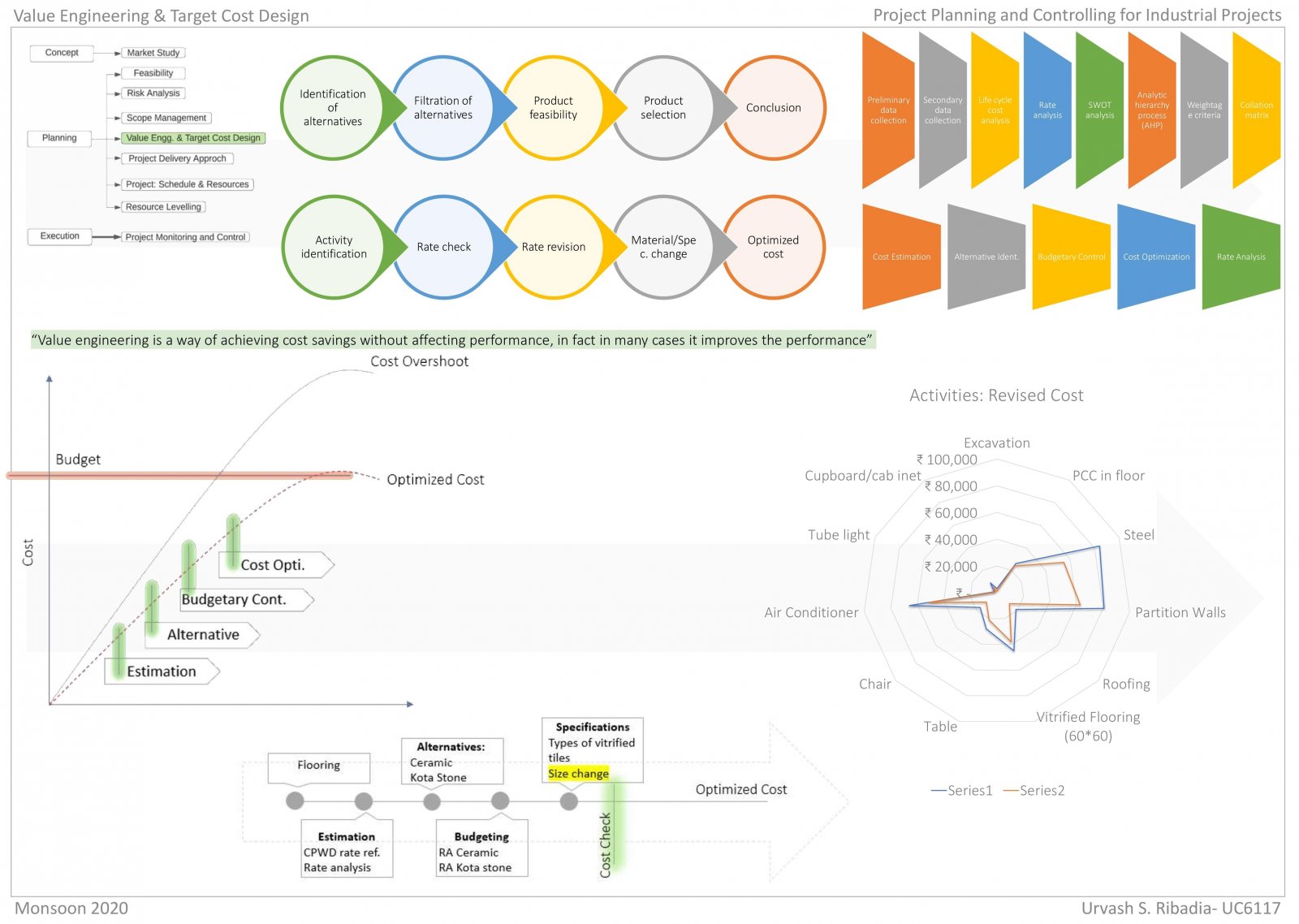

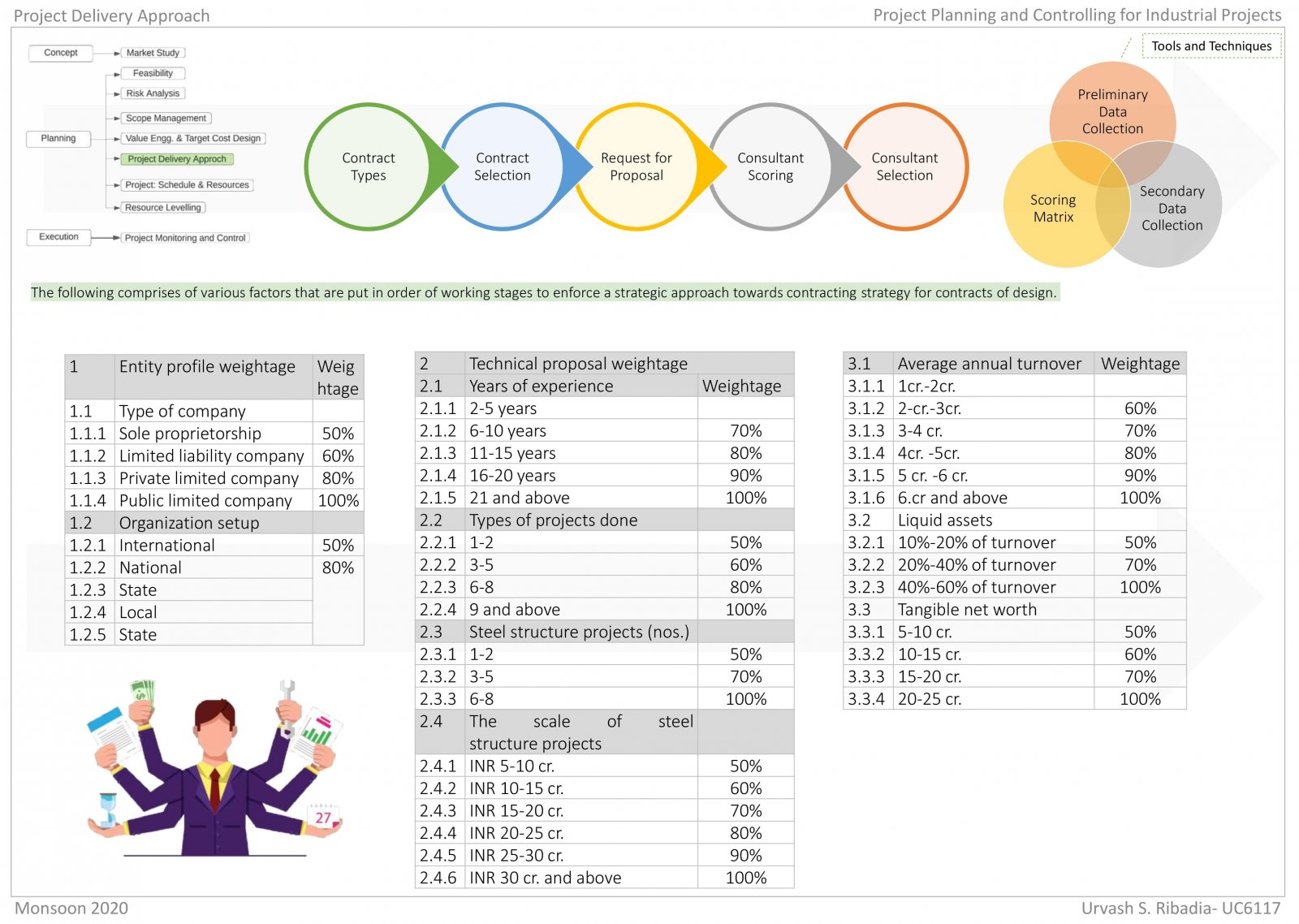

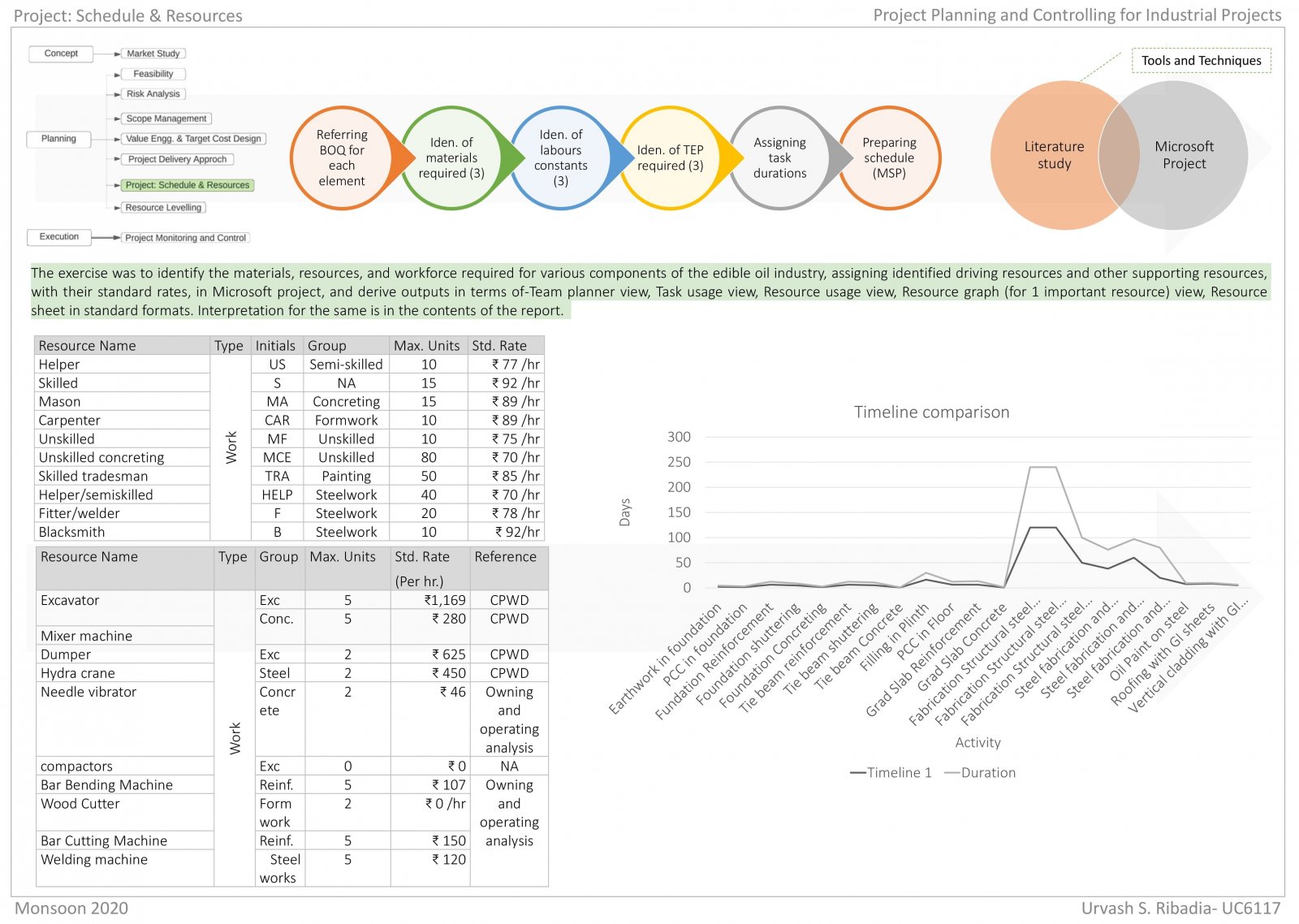

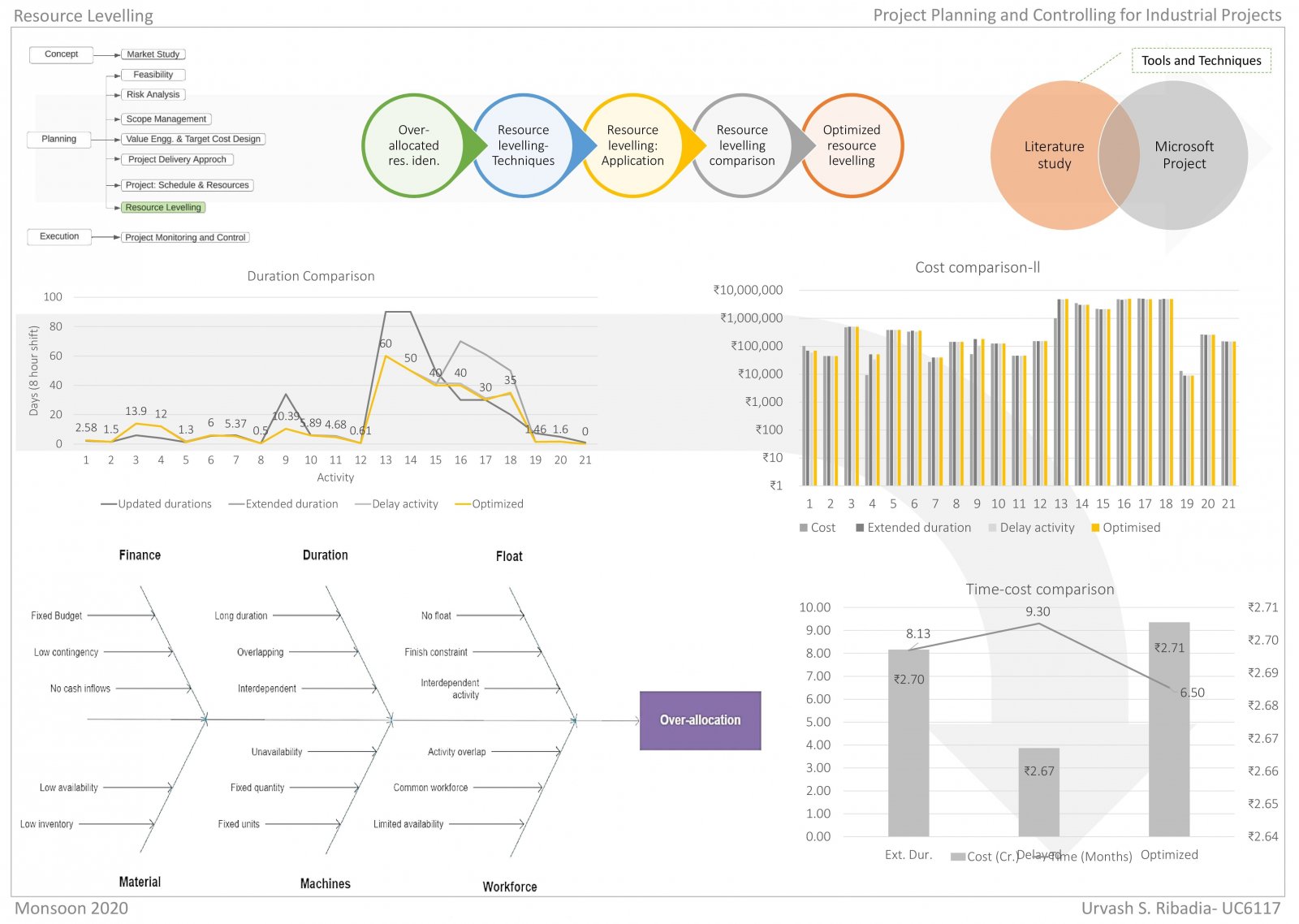

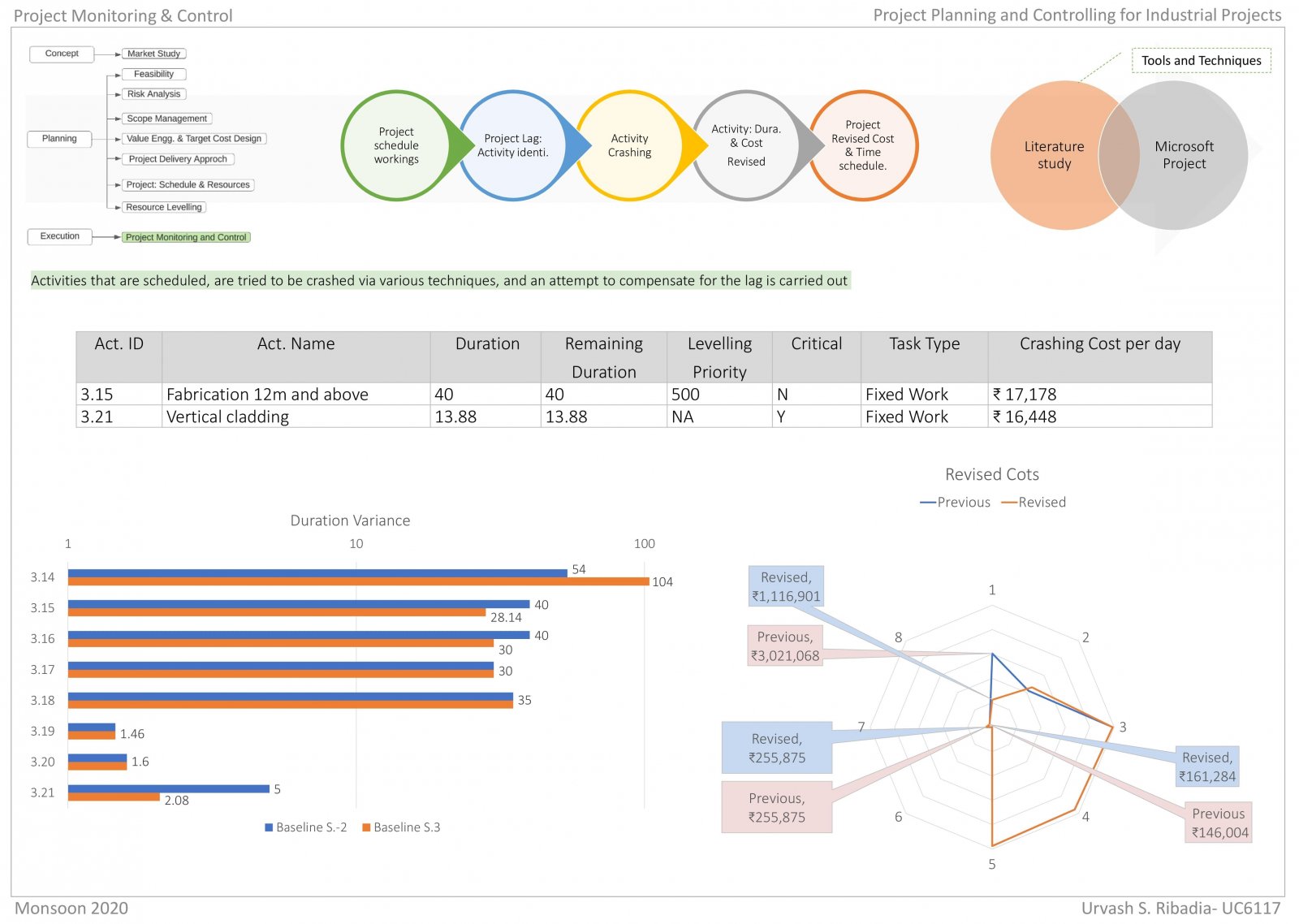

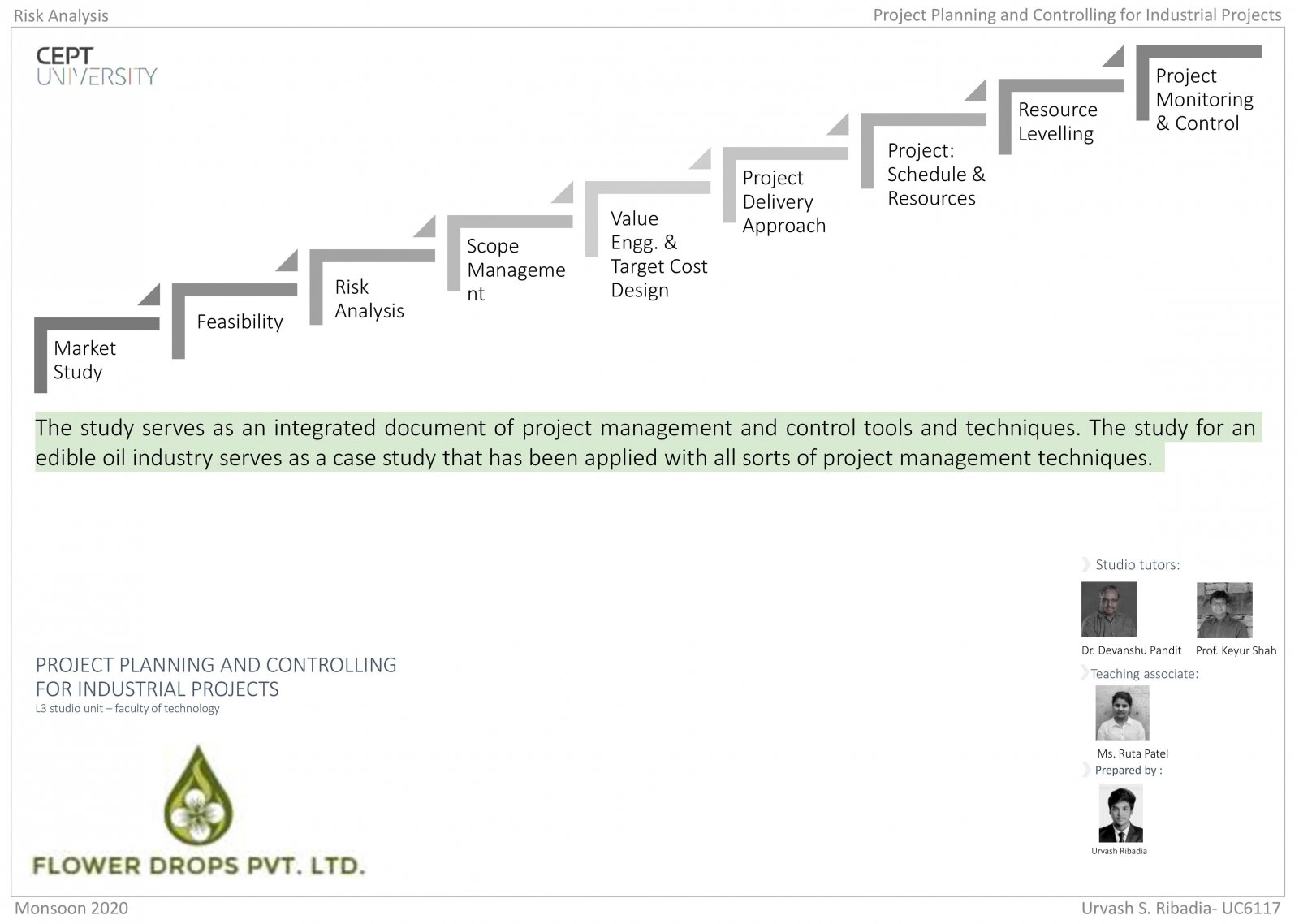

A detailed study backed by the implementation of various Project Management tools and techniques to plan an industrial project of the Edible oil-producing industry for a demand of 110 tonnes per day. The study comprises of detailed analysis of the project life-cycle and the factors governed by it. Implementation of these Project Management tools and techniques to produce an optimized and well planned, economically efficient baseline, that serves the project for its planning, execution, controlling, and monitoring demand.

View Additional Work