Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

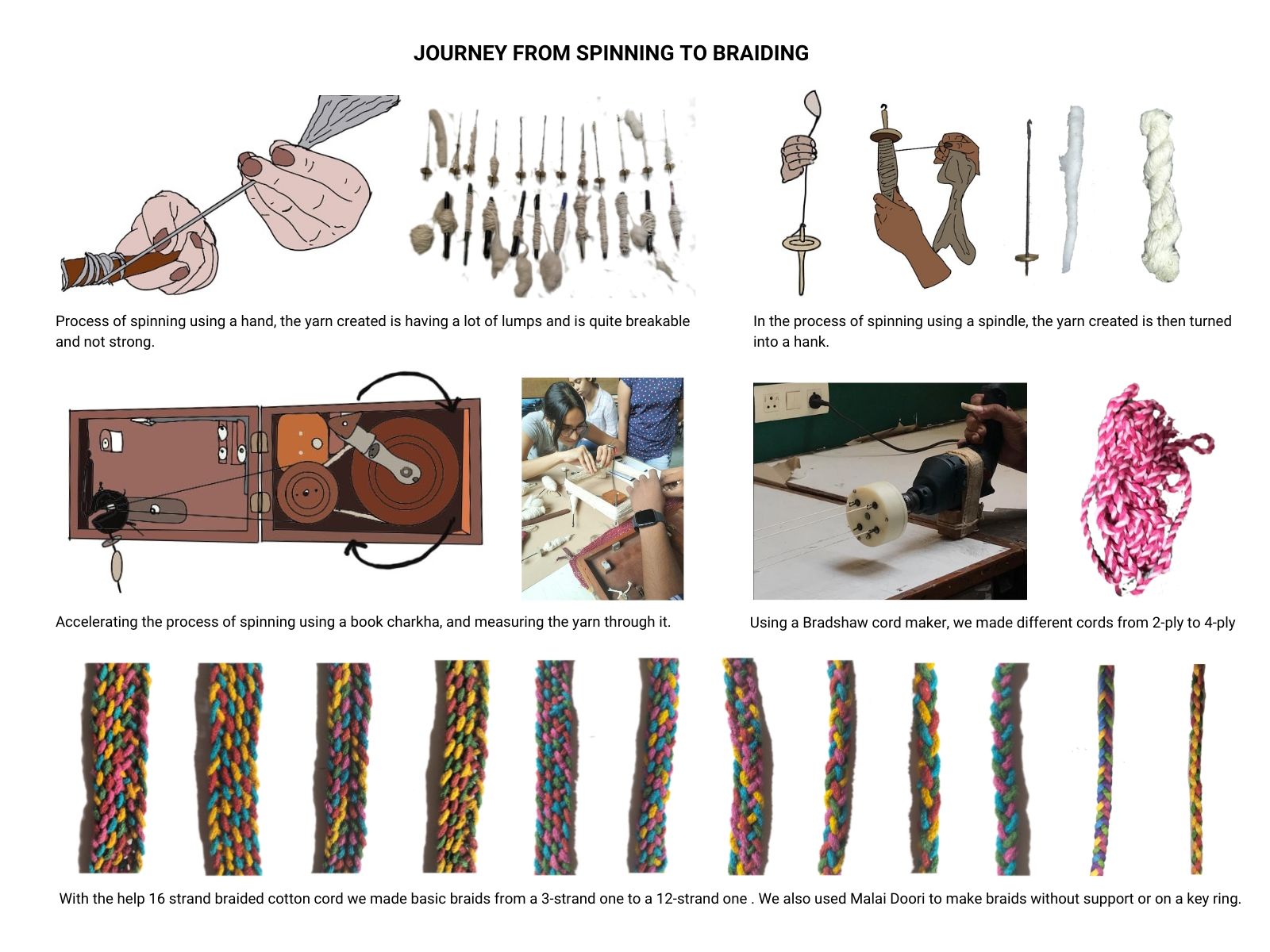

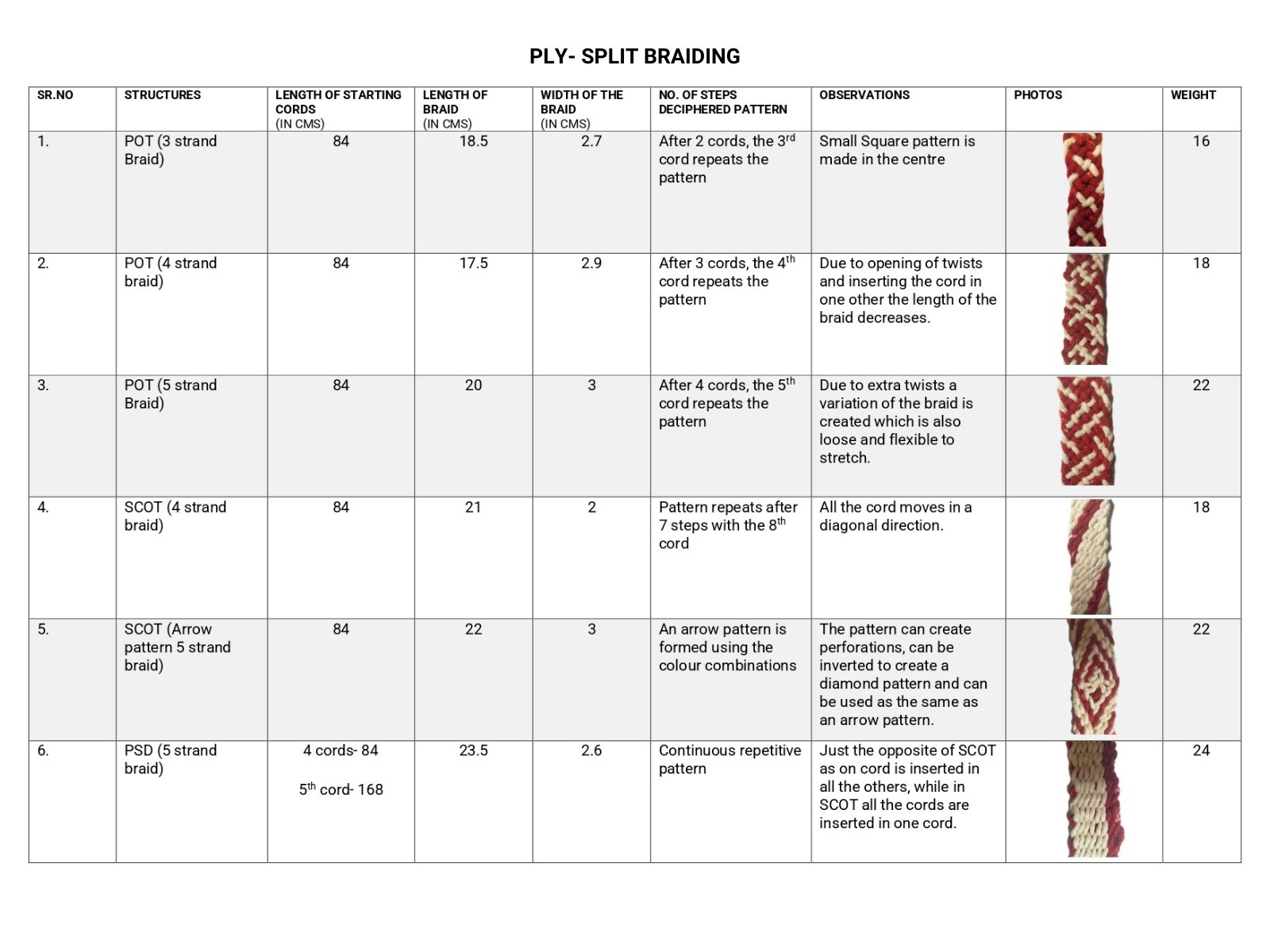

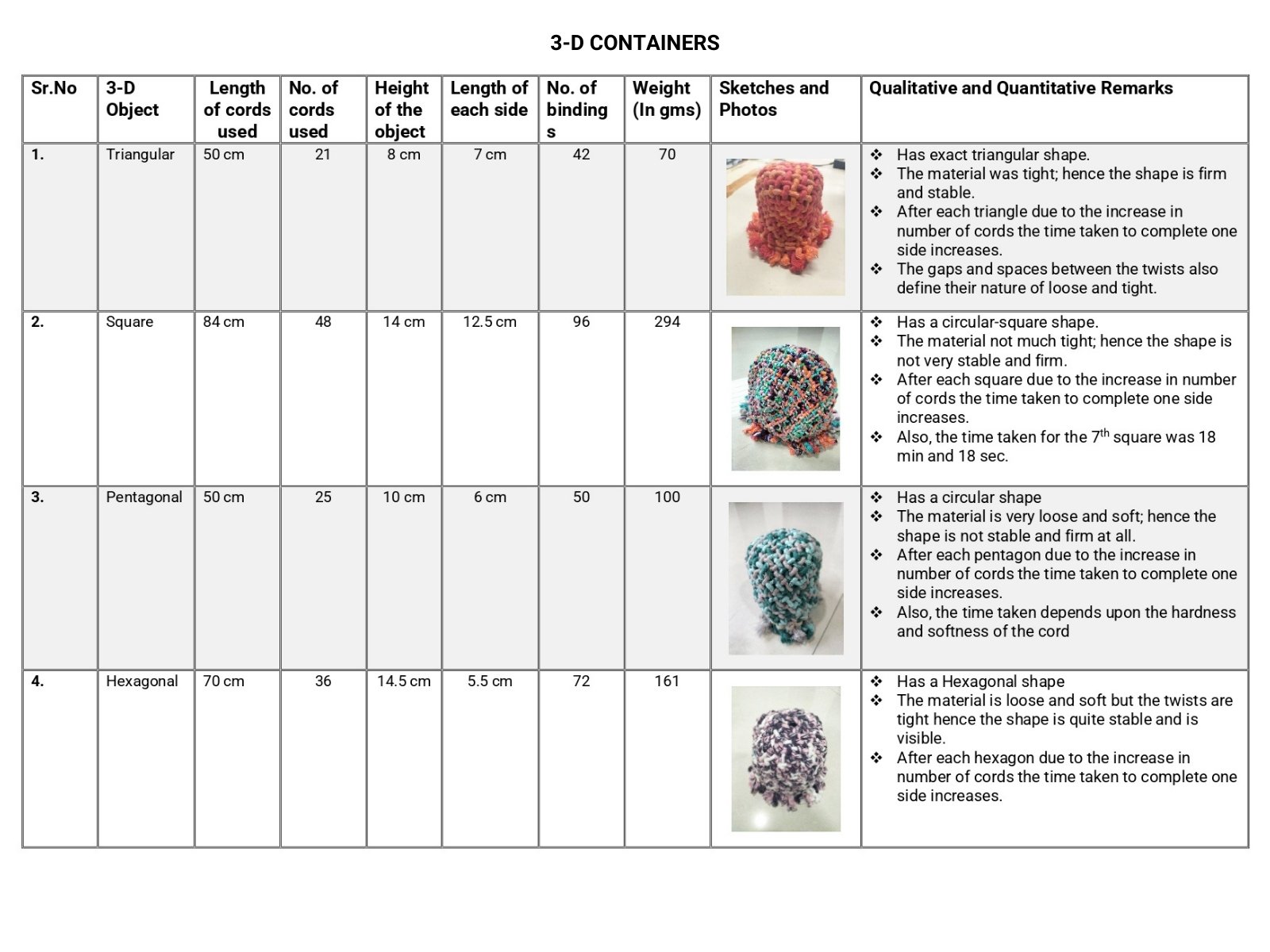

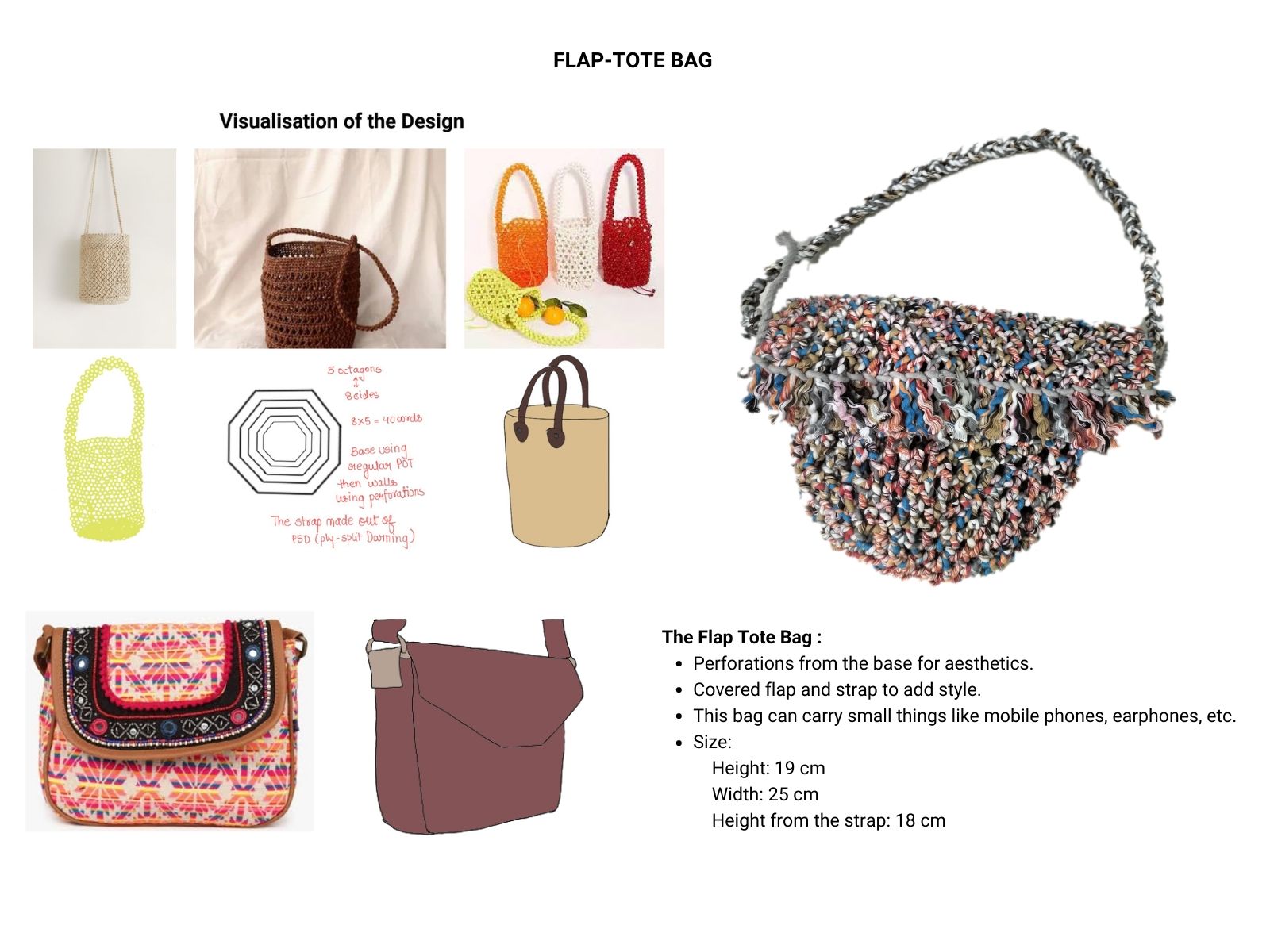

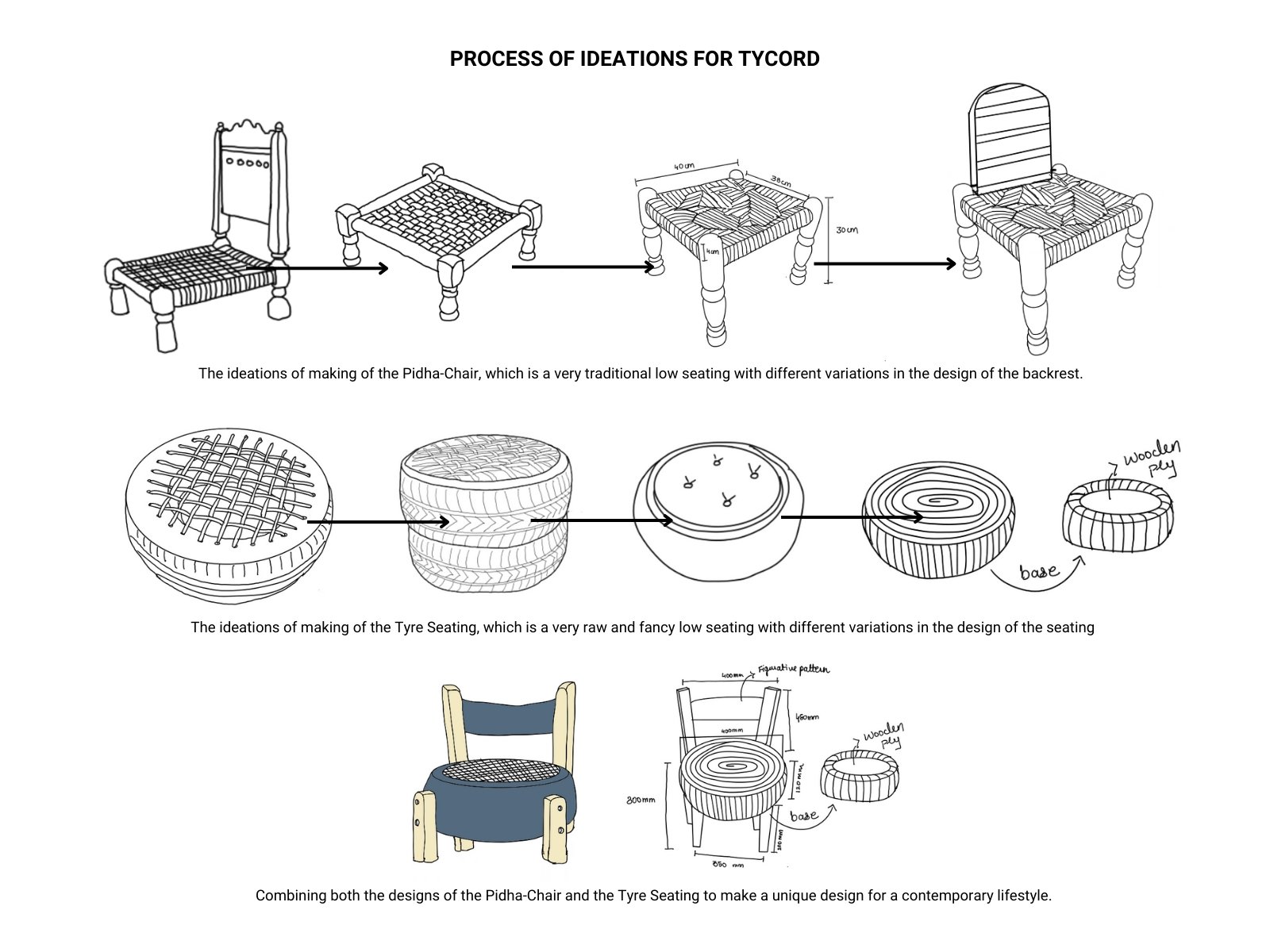

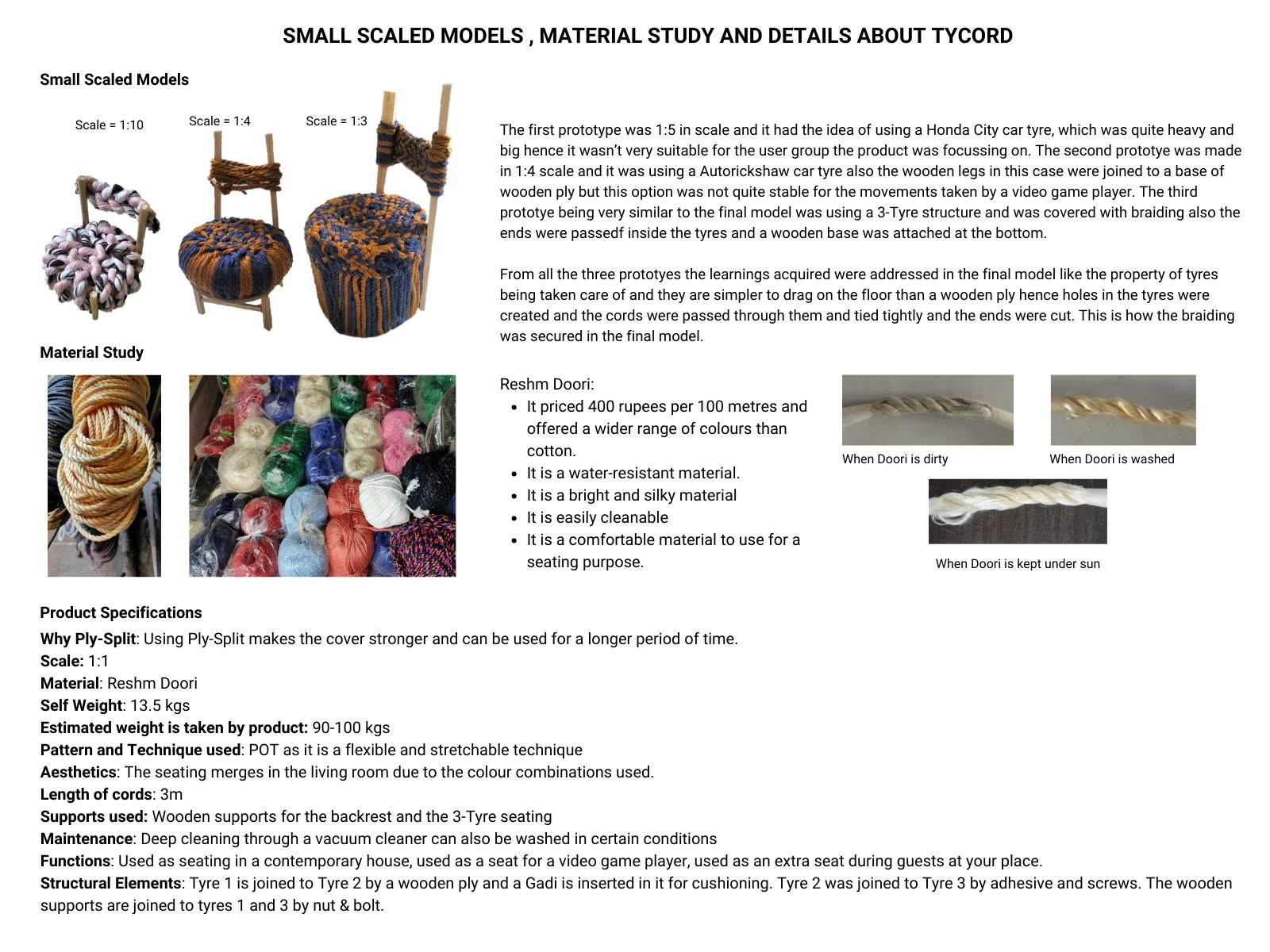

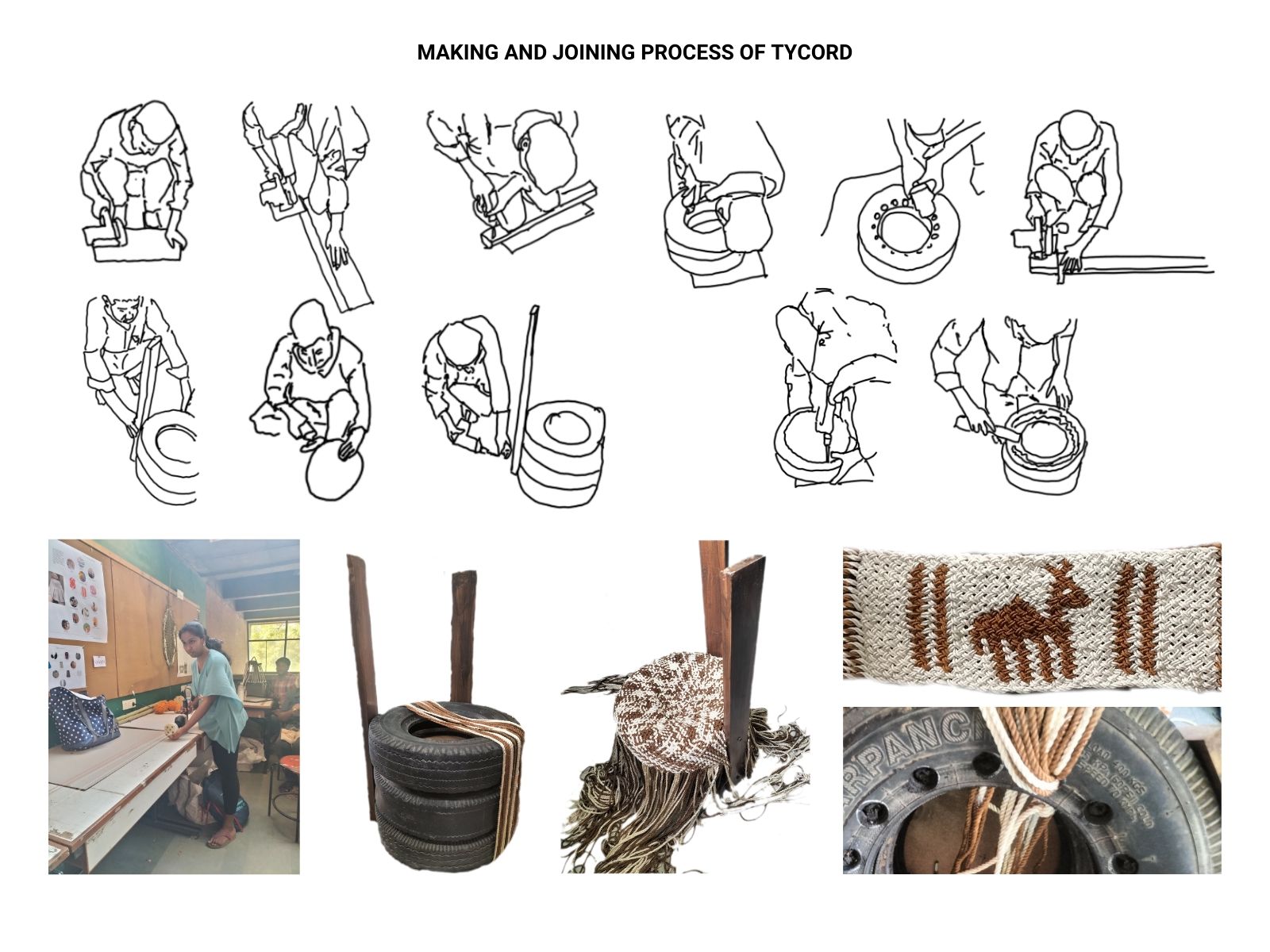

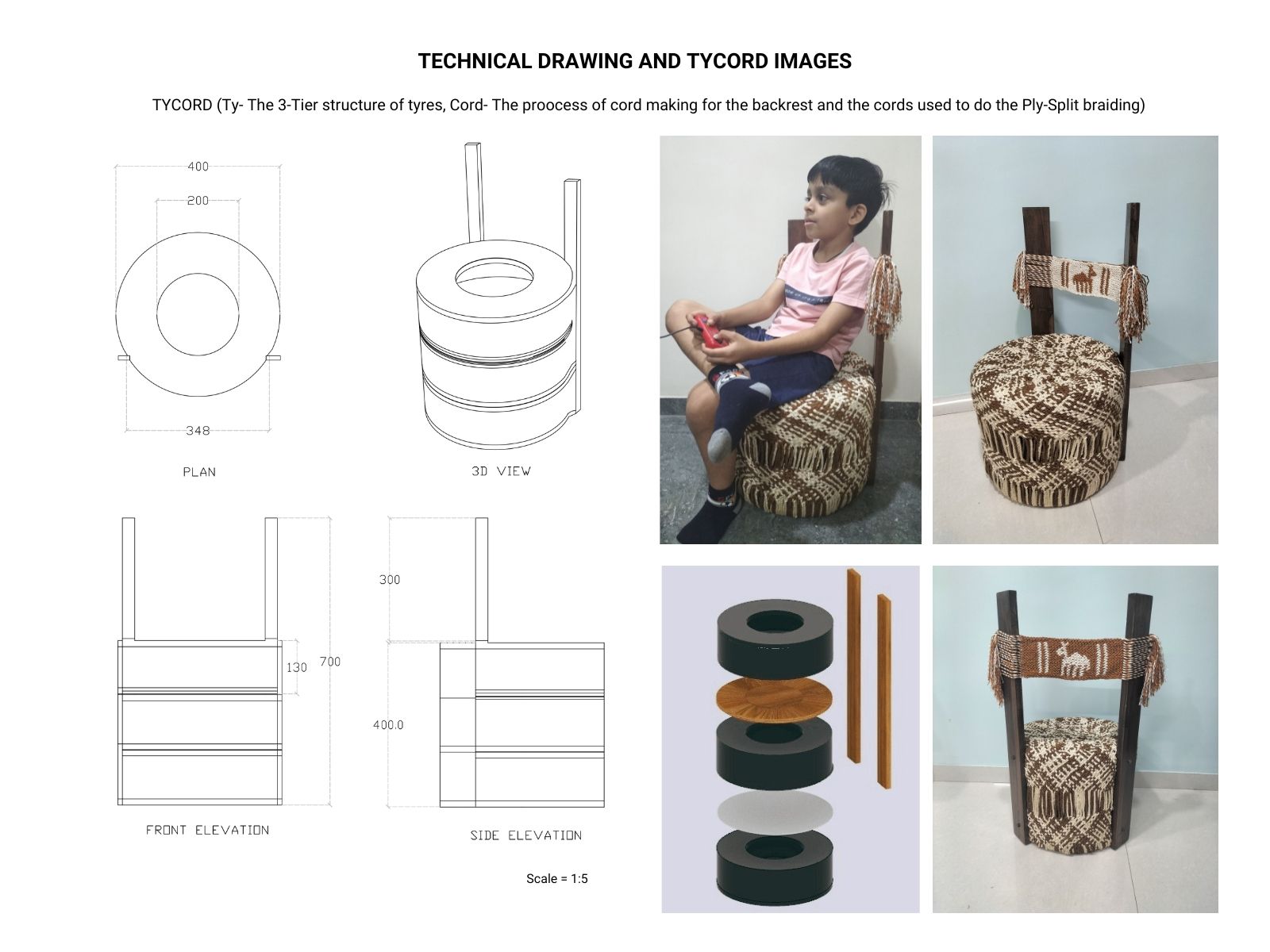

The studio revolves around learning the process of Ply-Split braiding. Various skills were acquired in the process of learning the different techniques of braiding. The studio introduced a design thinking process by exploration of new materials and techniques. These learnings were applied to make a 3-D product as the final exercise of the studio. The process started with understanding fibers through the process of spinning, followed by cord making, and learning techniques of braiding to make 3-D products by playing and exploring with different materials and combining them together.

View Additional Work