Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

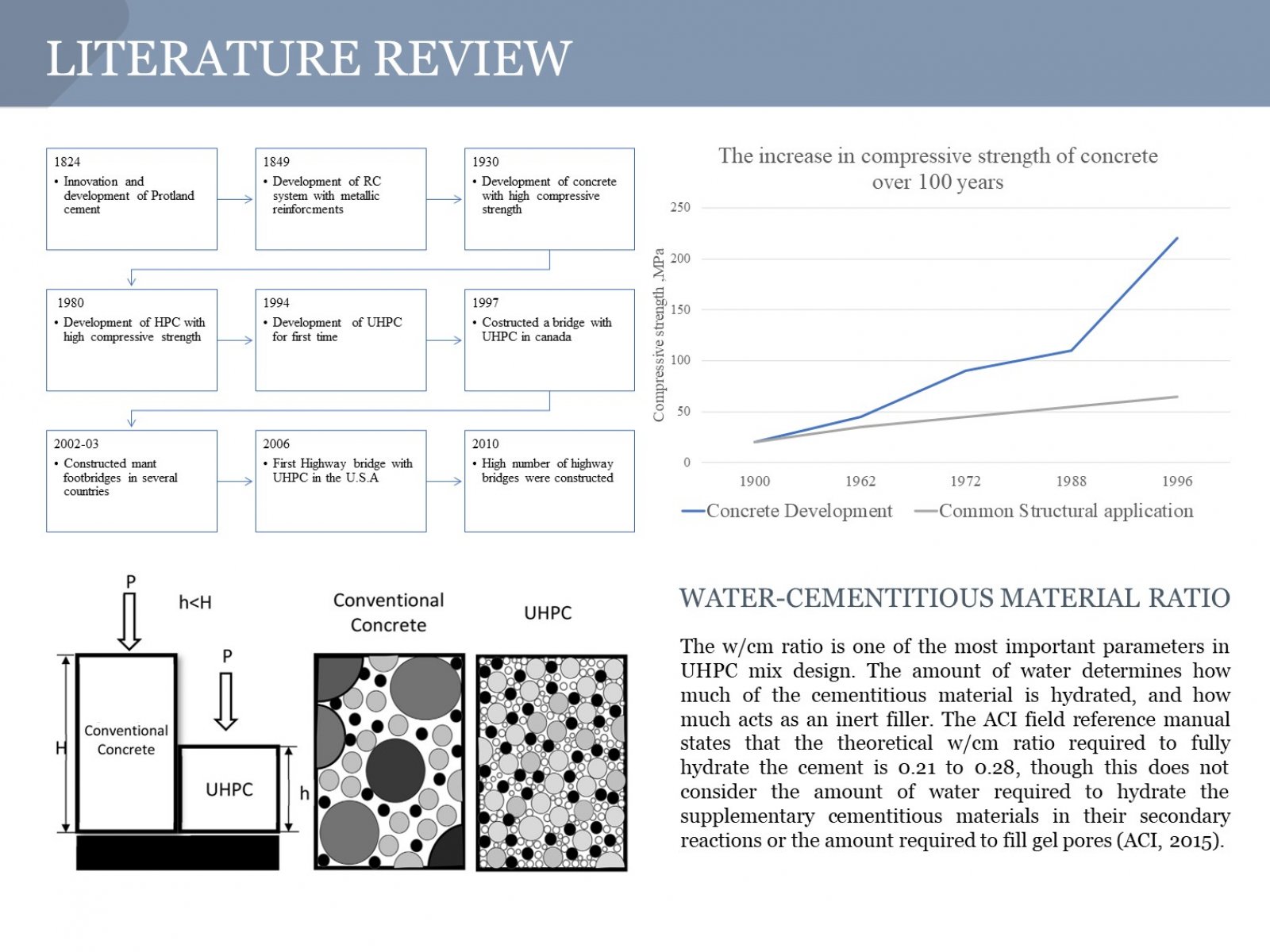

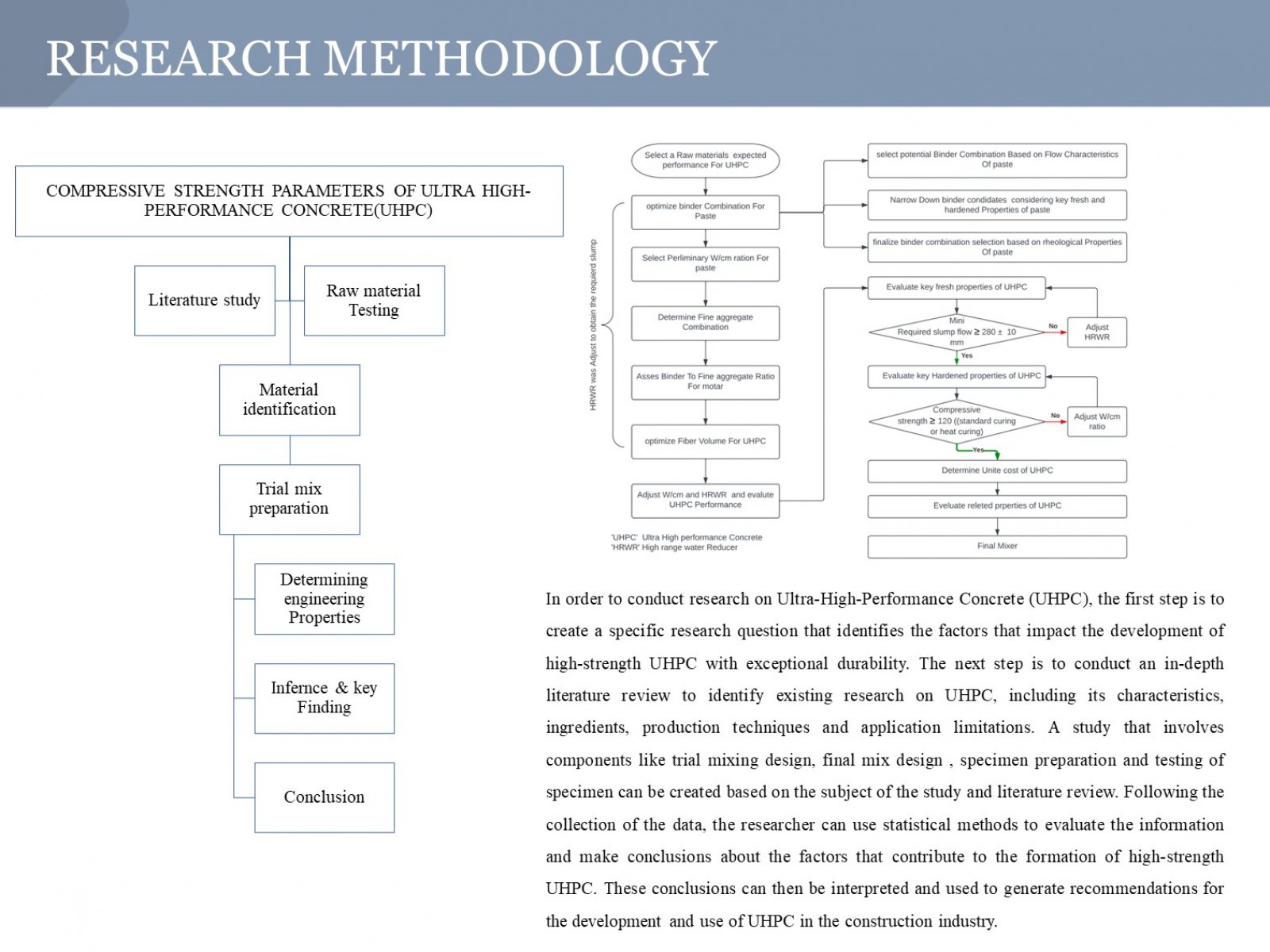

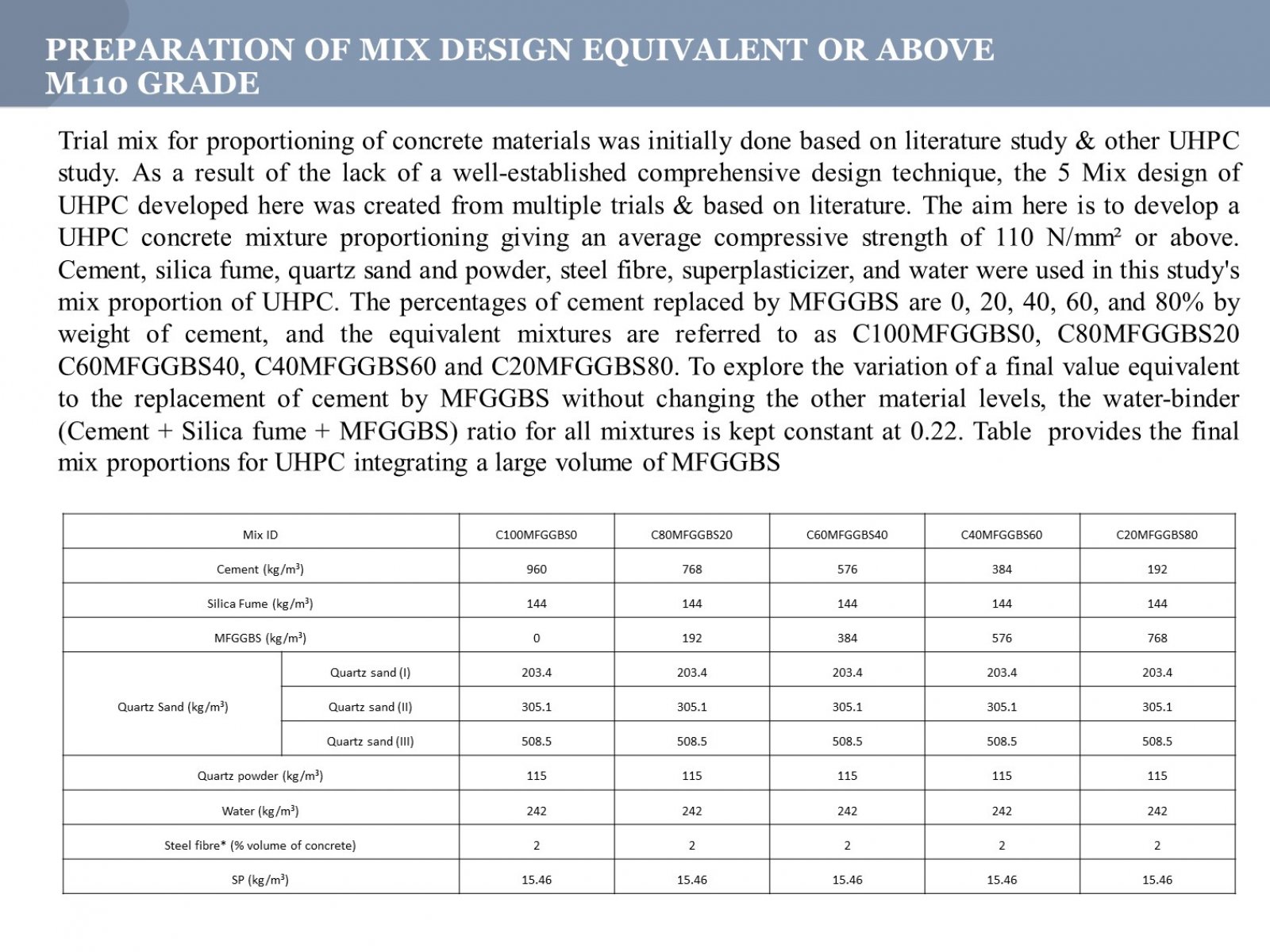

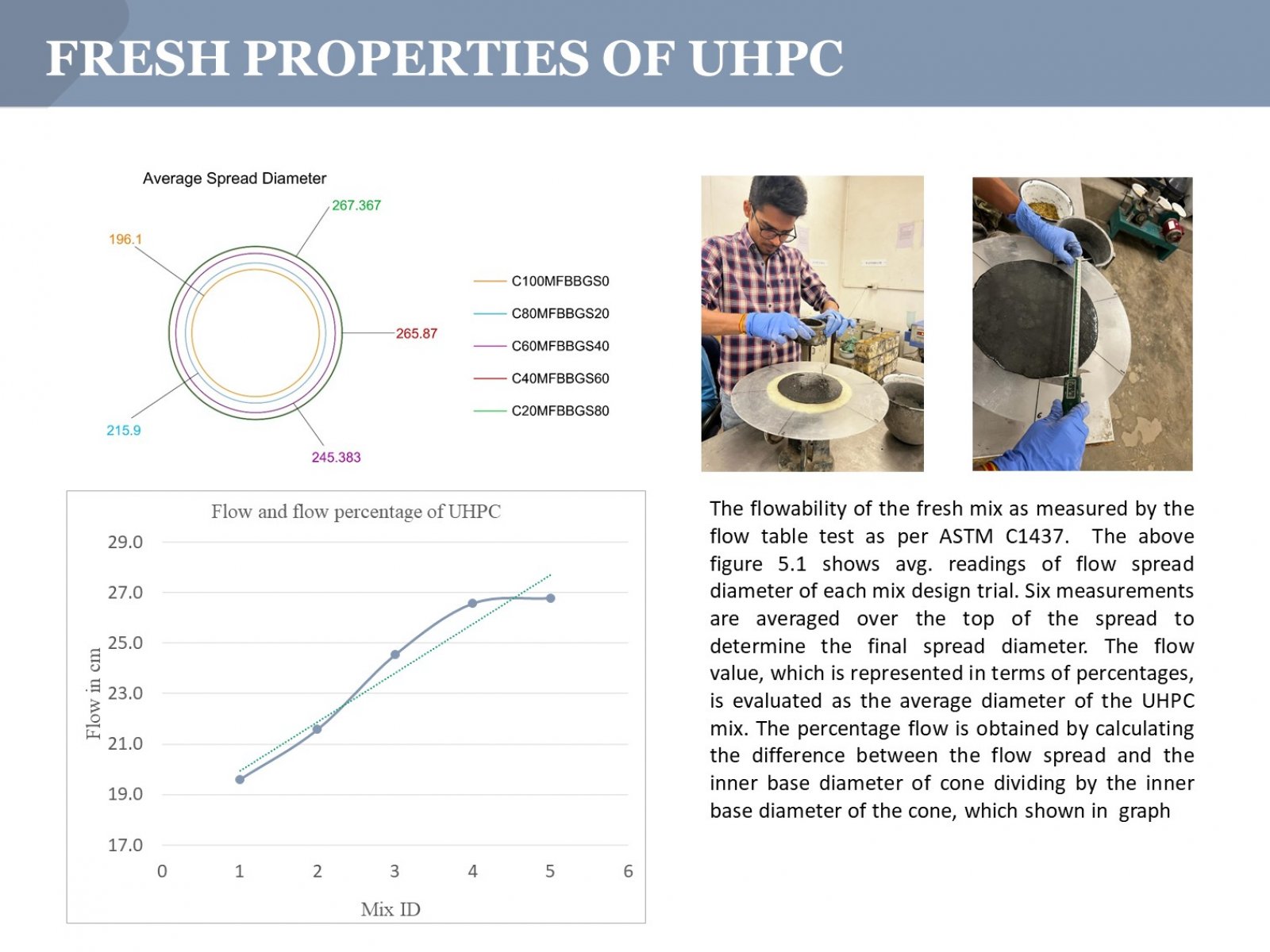

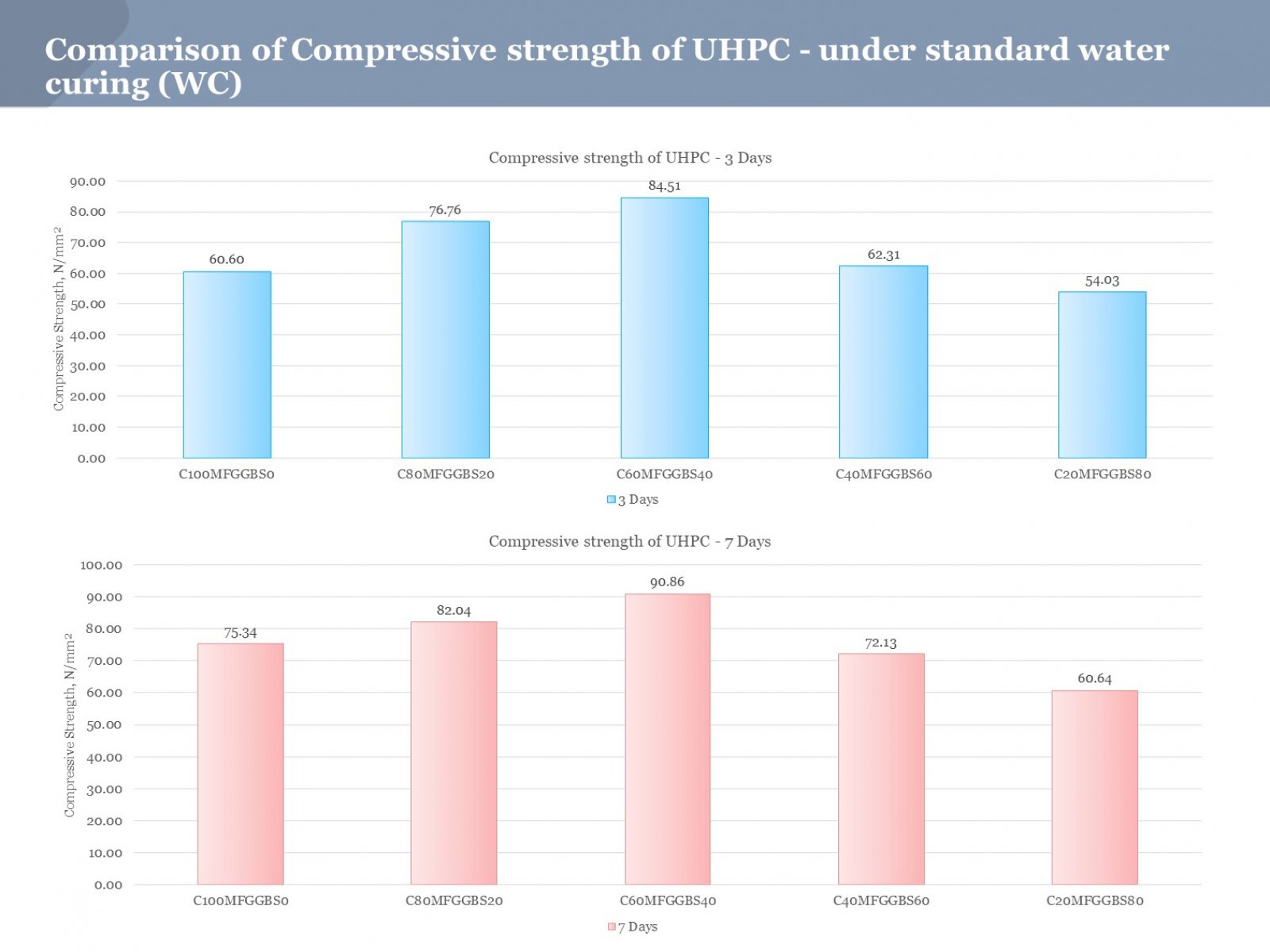

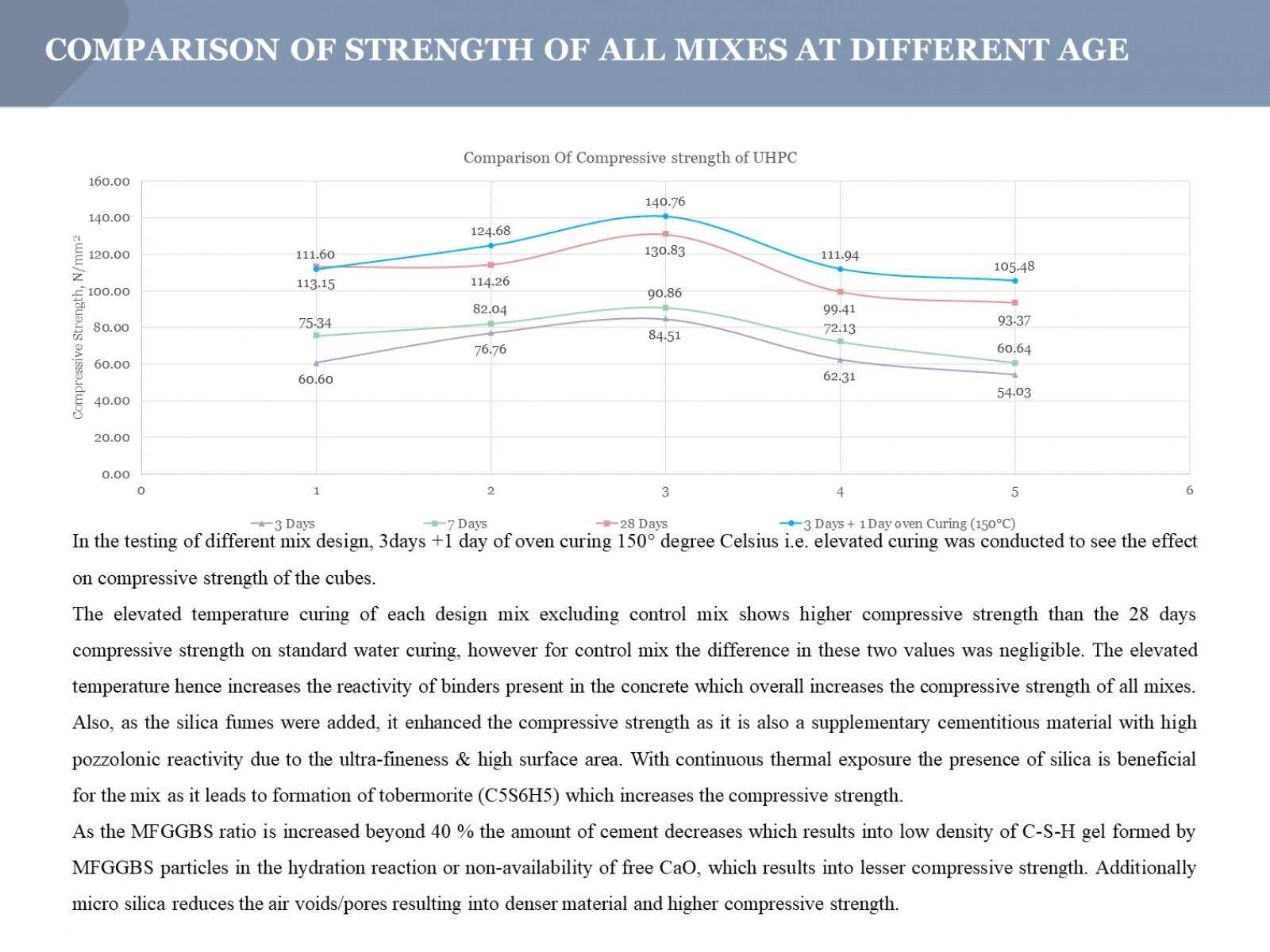

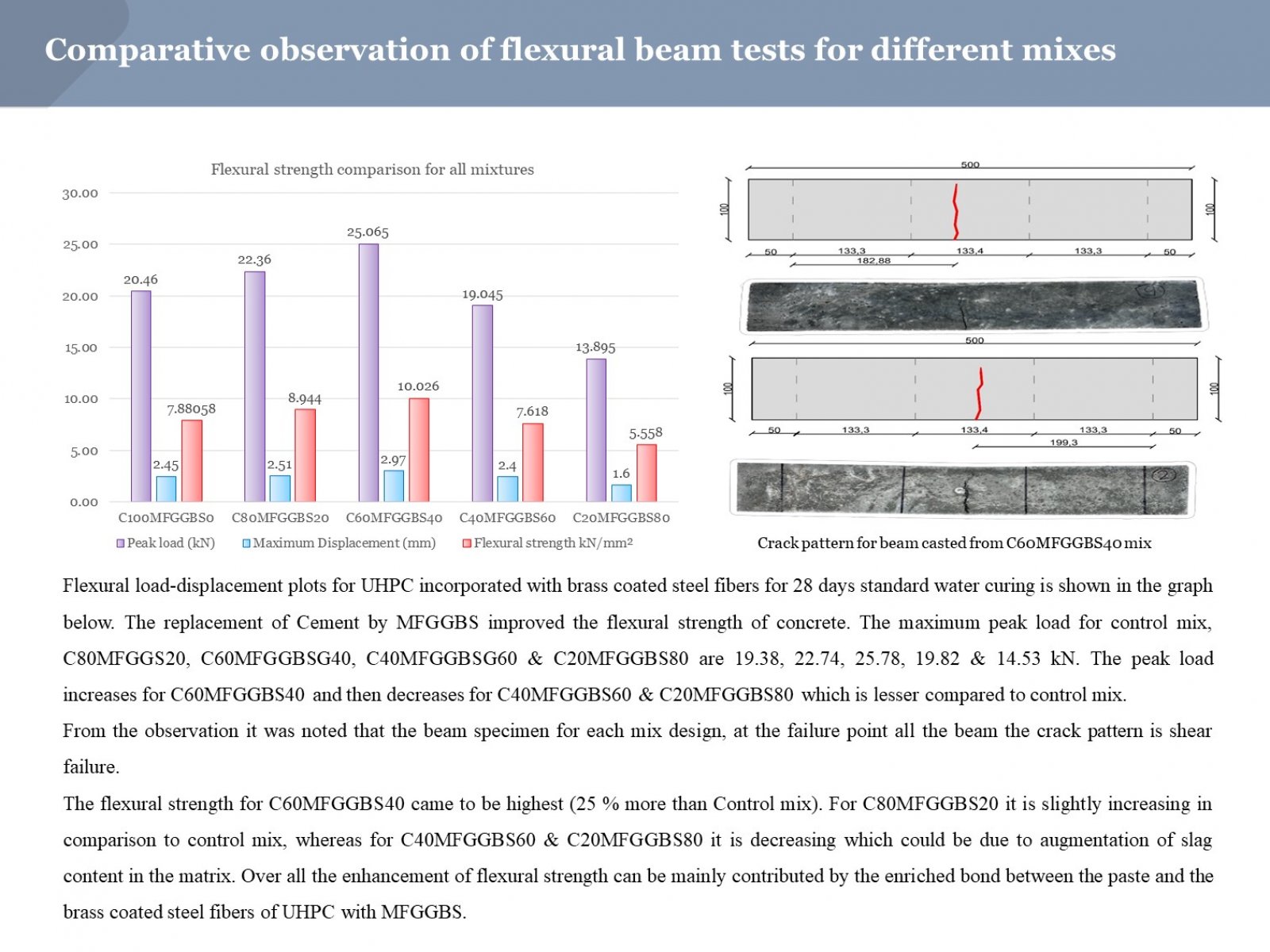

Ultra High-Performance Concrete (UHPC) is a relatively new type of concrete that offers exceptional mechanical and durability properties. However, the compressive strength parameters of UHPC are not yet fully understood, and further research is necessary to evaluate its performance. This directed research project aims to investigate the compressive strength parameters of UHPC prepared using cement, silica fume, silica sand, quartz powder & MFGGBS etc through a series of experimental tests. The study will involve the production of UHPC samples with varying mix proportions and curing conditions, followed by compression tests to measure their compressive strength and deformation characteristics. The results of the study will be analysed to identify the factors that affect the compressive strength of UHPC, such as the type and quantity of the constituent materials, the method of sample preparation, curing temperature and time. The findings will contribute to the understanding of the compressive strength properties of UHPC and may lead to the development of new design guidelines for UHPC structures. Overall, this research project is expected to provide valuable insights into the compressive strength parameters of UHPC and contribute to the ongoing efforts to improve the performance of this advanced construction material. The use of supplementary cementitious materials (SCMs) has been increasing in the concrete industry over the last three decades as a means of reducing environmental issues. One potential material is Microfine ground granulated blast furnace slag (MFGGBS), which can help to mitigate waste by using industrial by-products. In this study, MFGGBS is used to replace up to 80% of cement in ultra-high-performance concrete (UHPC). The study evaluates the flowability, strength, durability, and flexural properties of UHPC with high levels of MFGGBS under two curing conditions (standard water and elevated temperature). The results show that up to 40% cement replacement with MFGGBS under standard water curing significantly improves the hardened properties of UHPC. Elevated temperature curing further improves its performance up to 60% cement replacement level.

View Additional Work