Your browser is out-of-date!

For a richer surfing experience on our website, please update your browser. Update my browser now!

For a richer surfing experience on our website, please update your browser. Update my browser now!

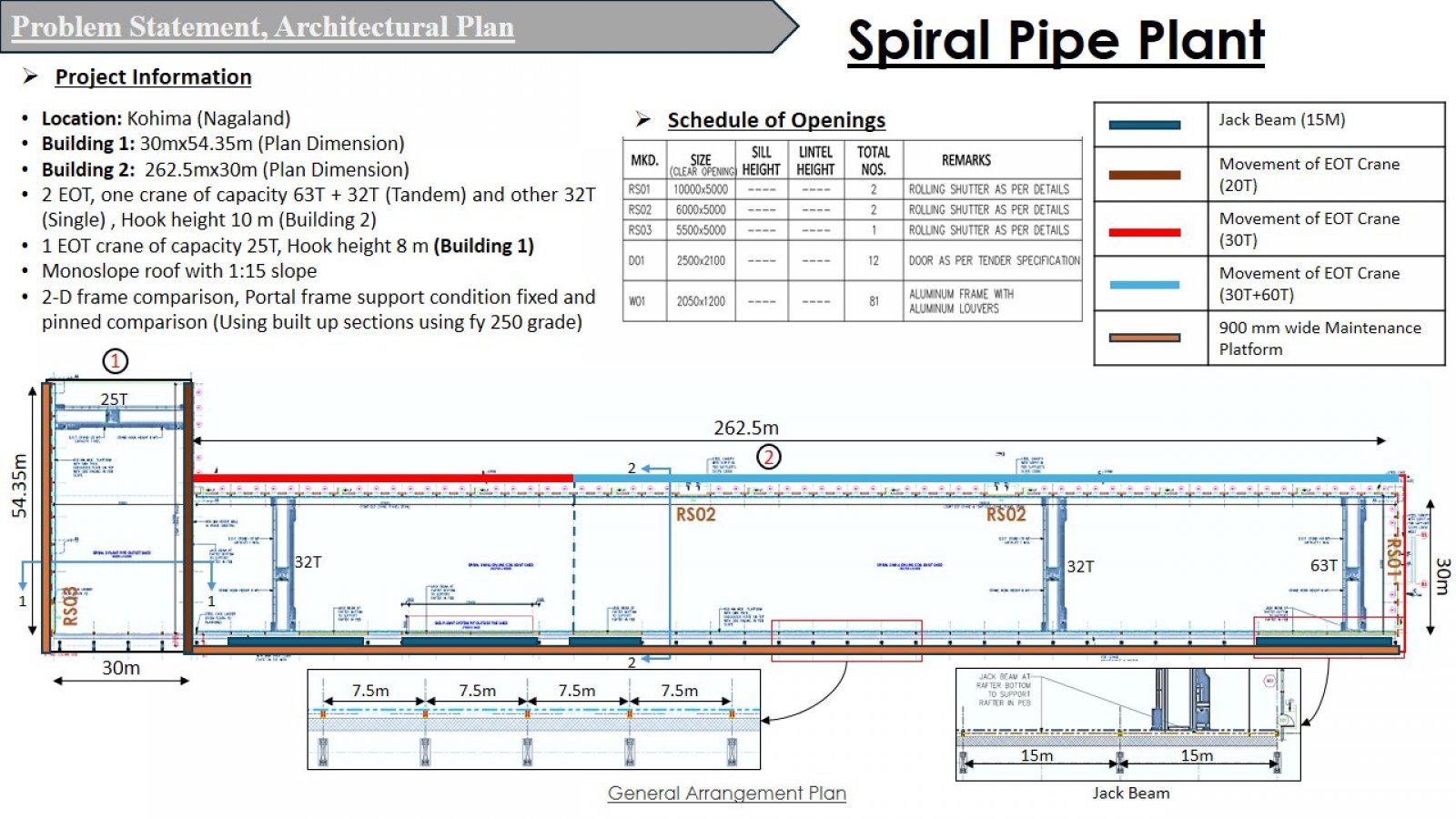

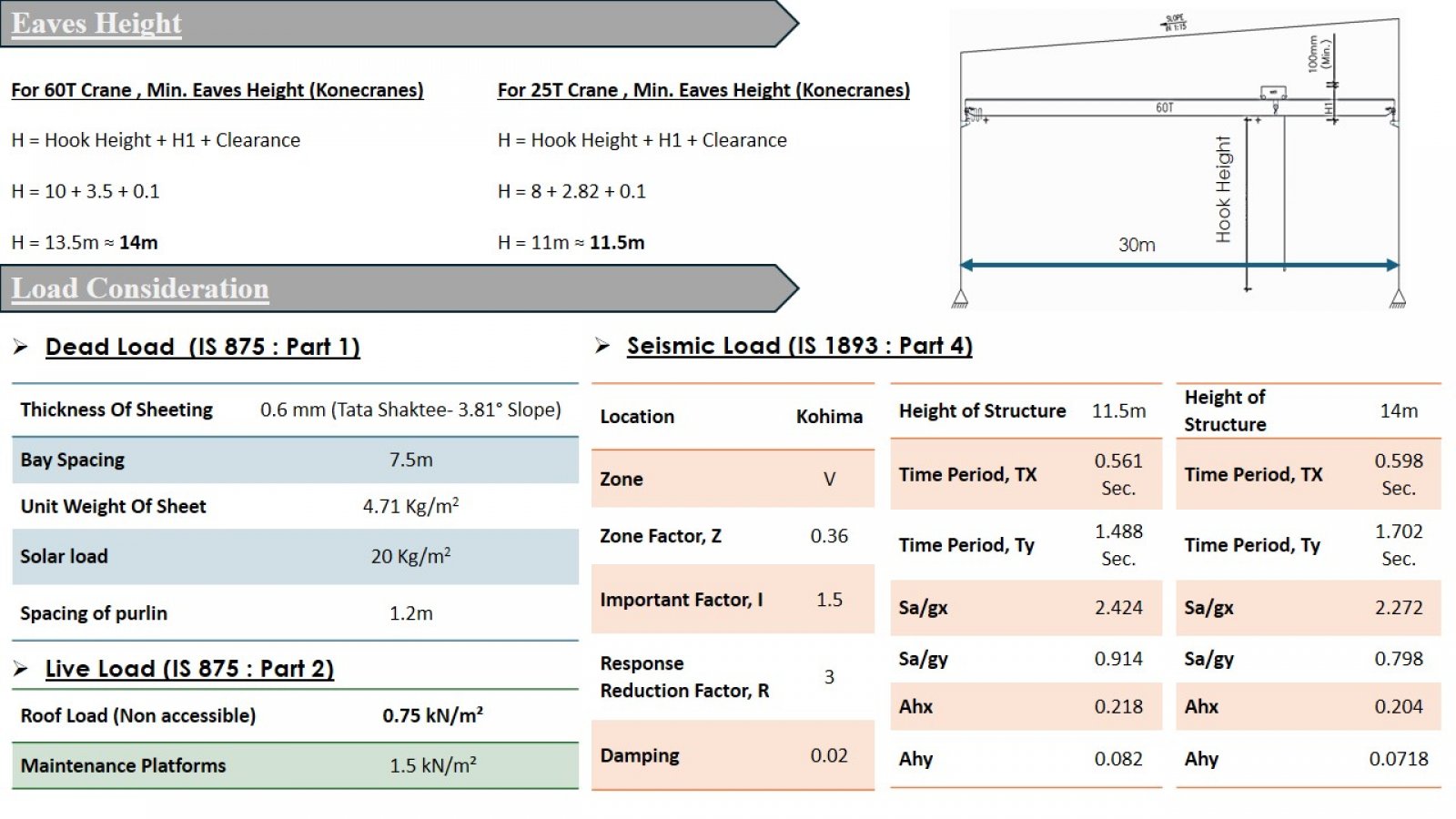

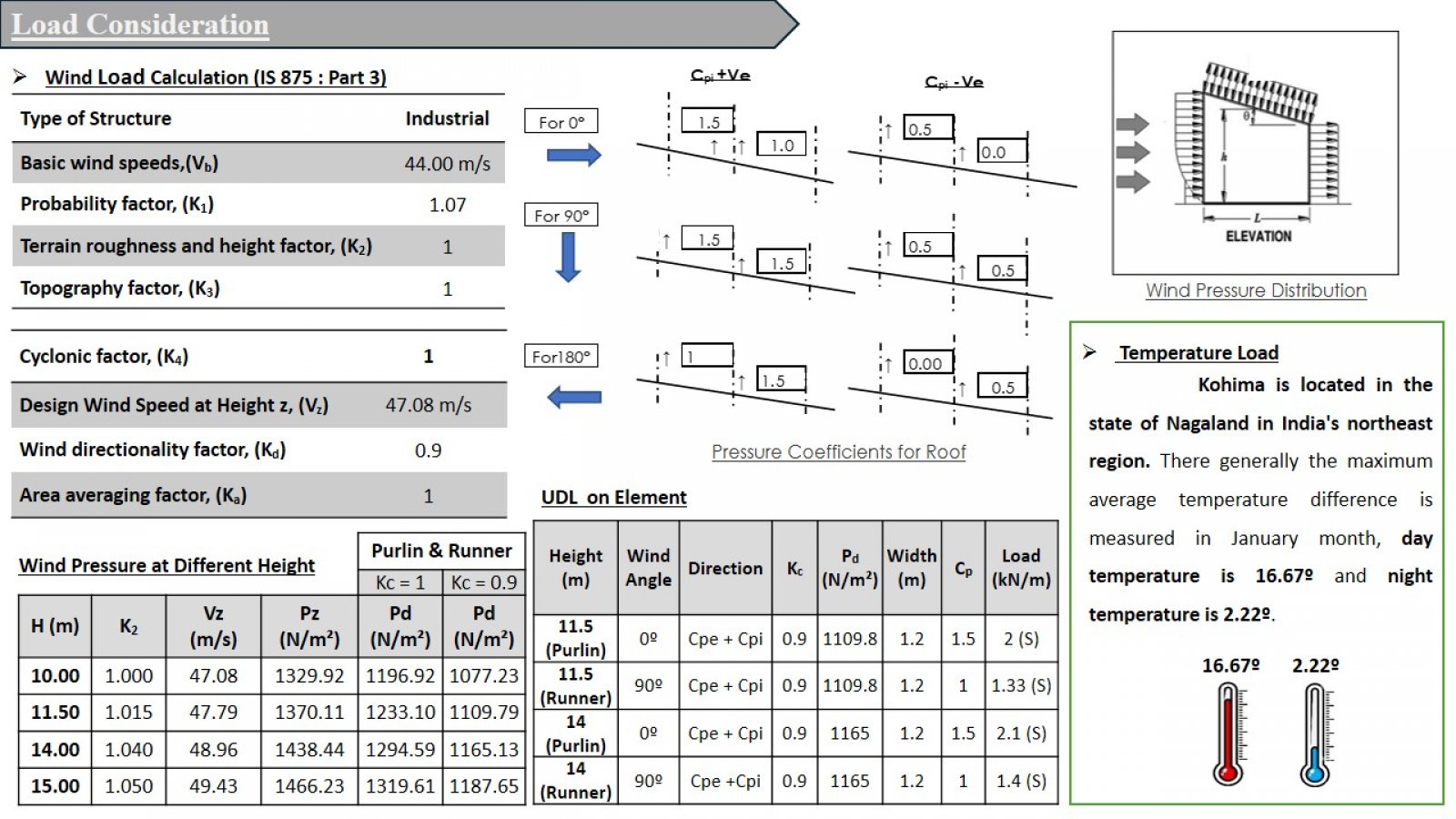

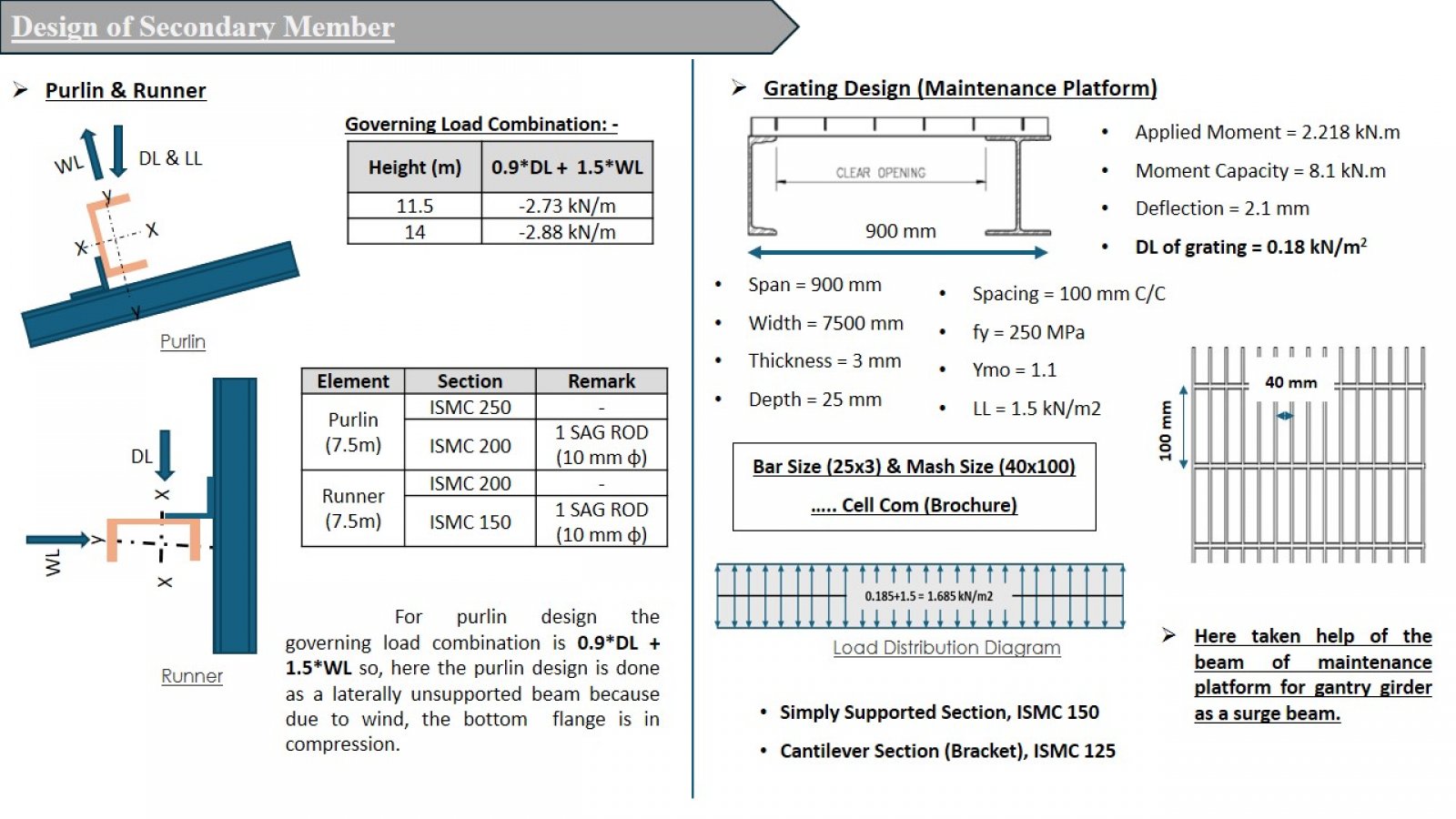

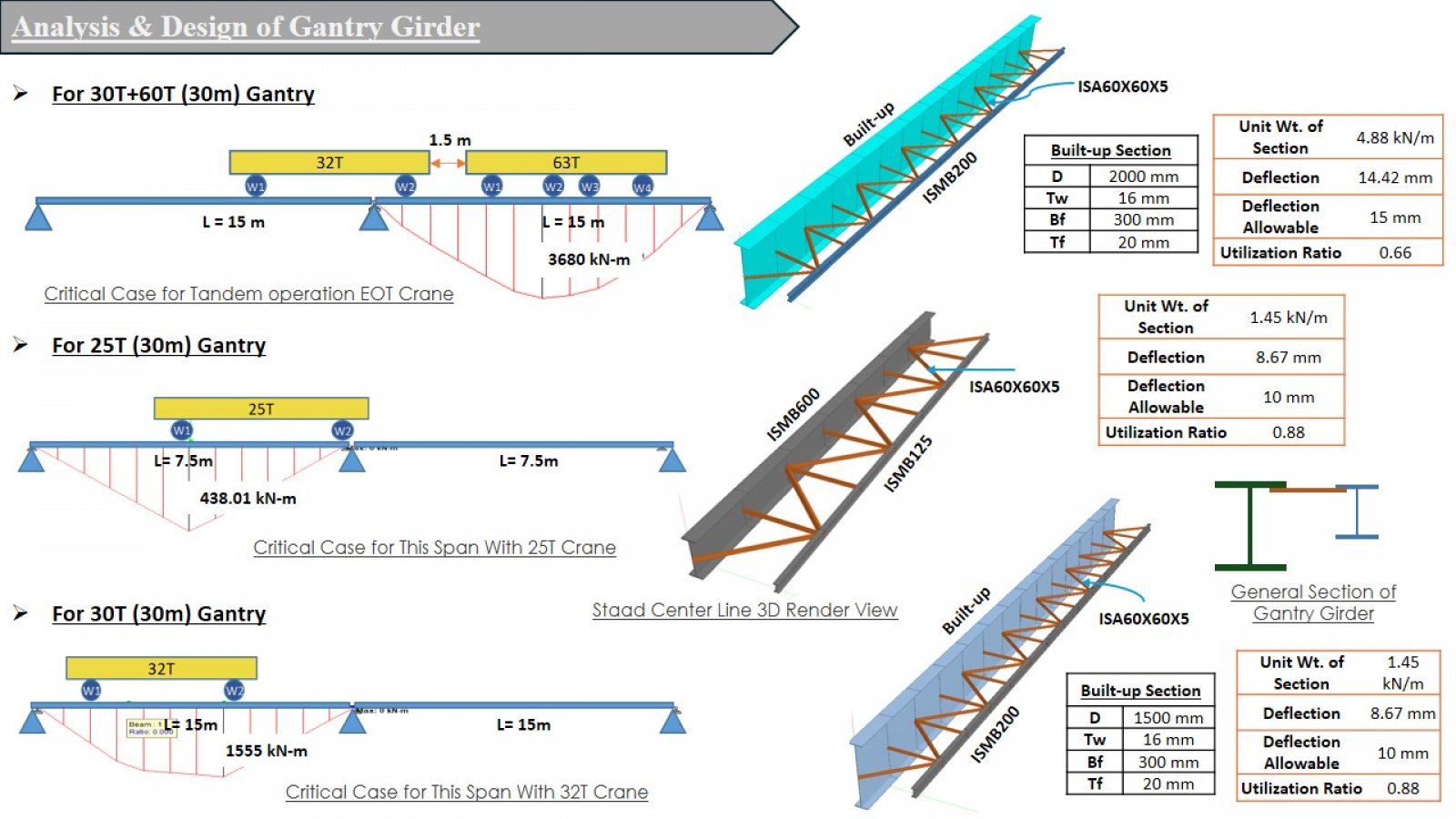

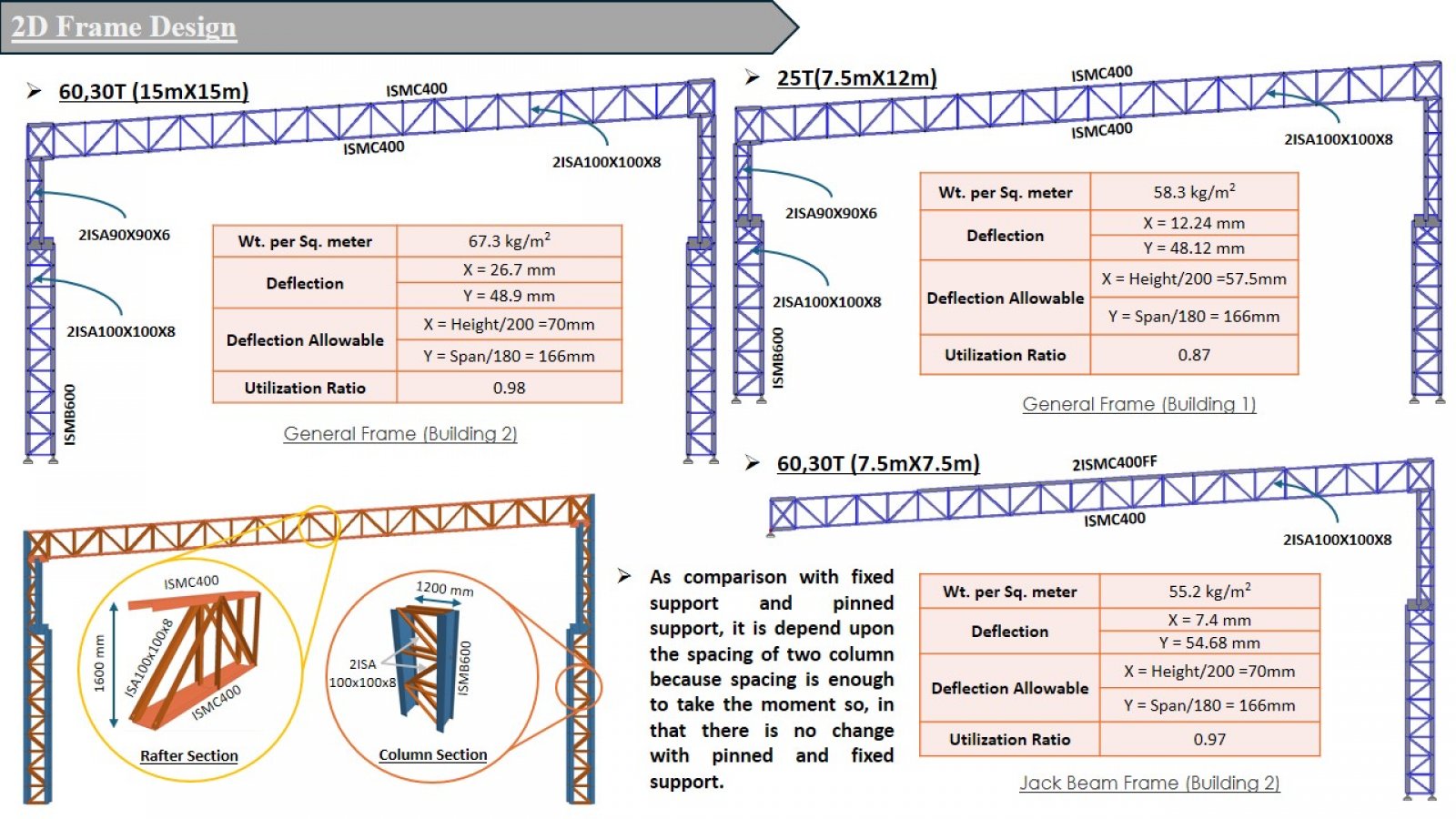

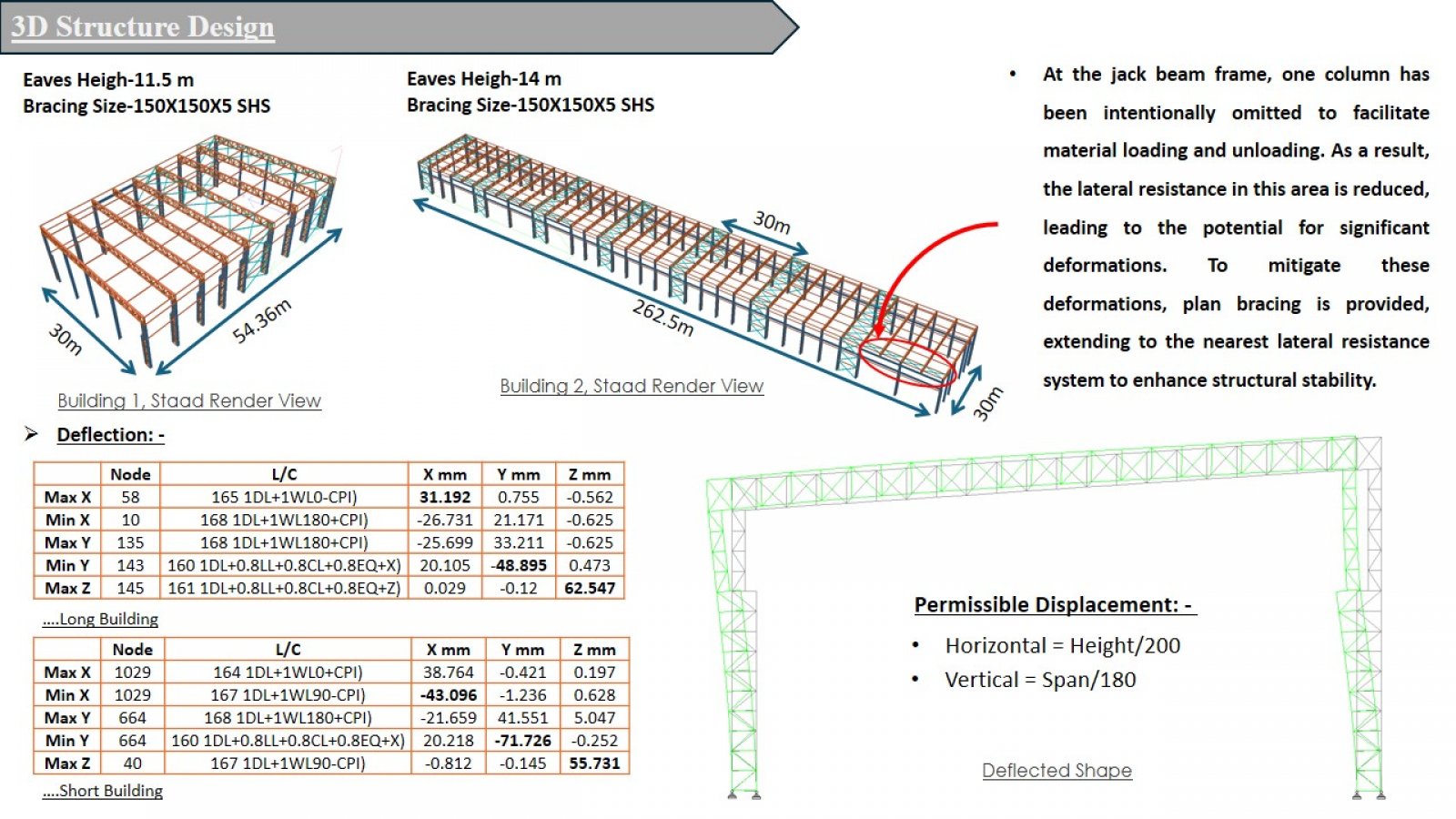

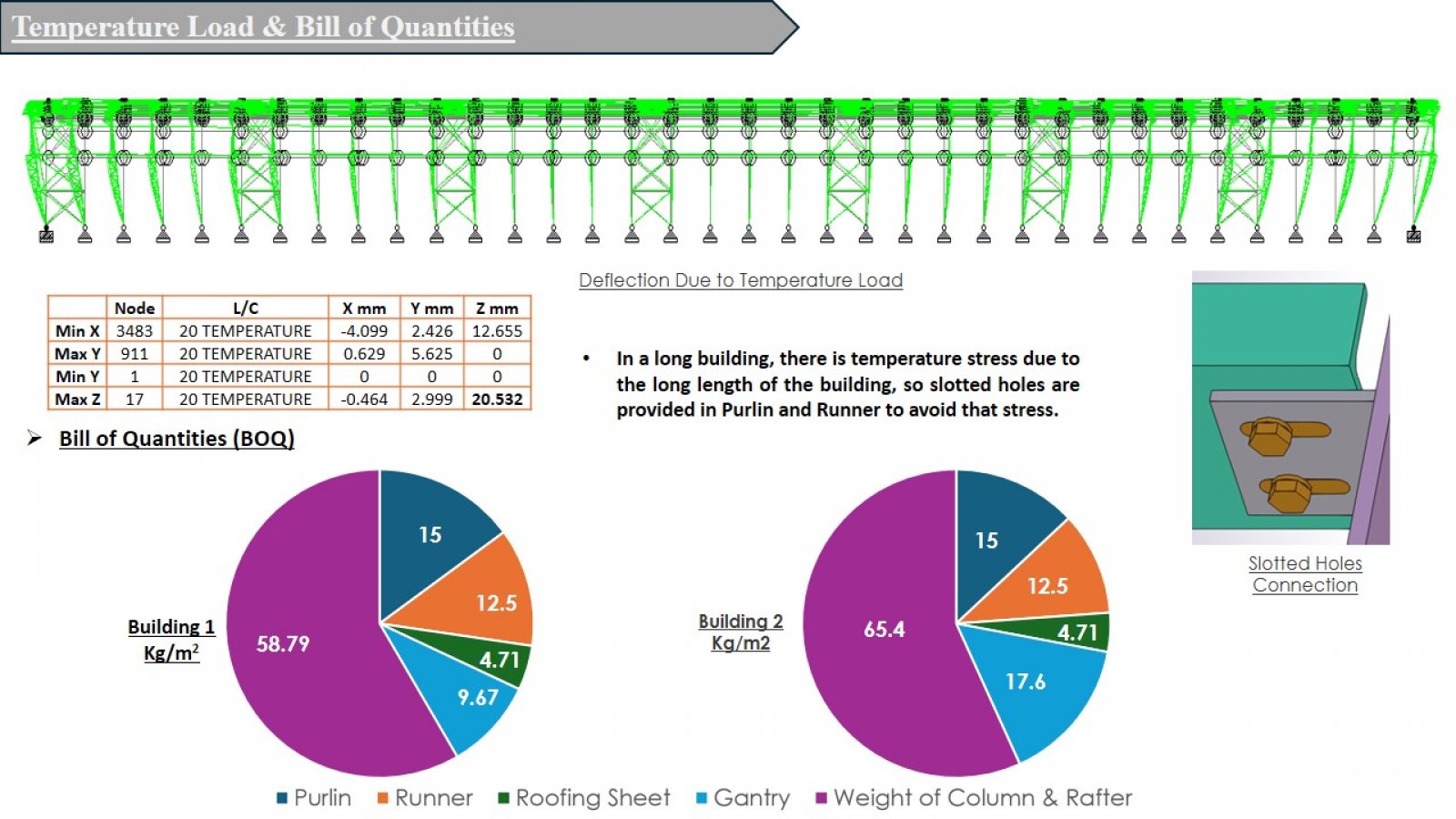

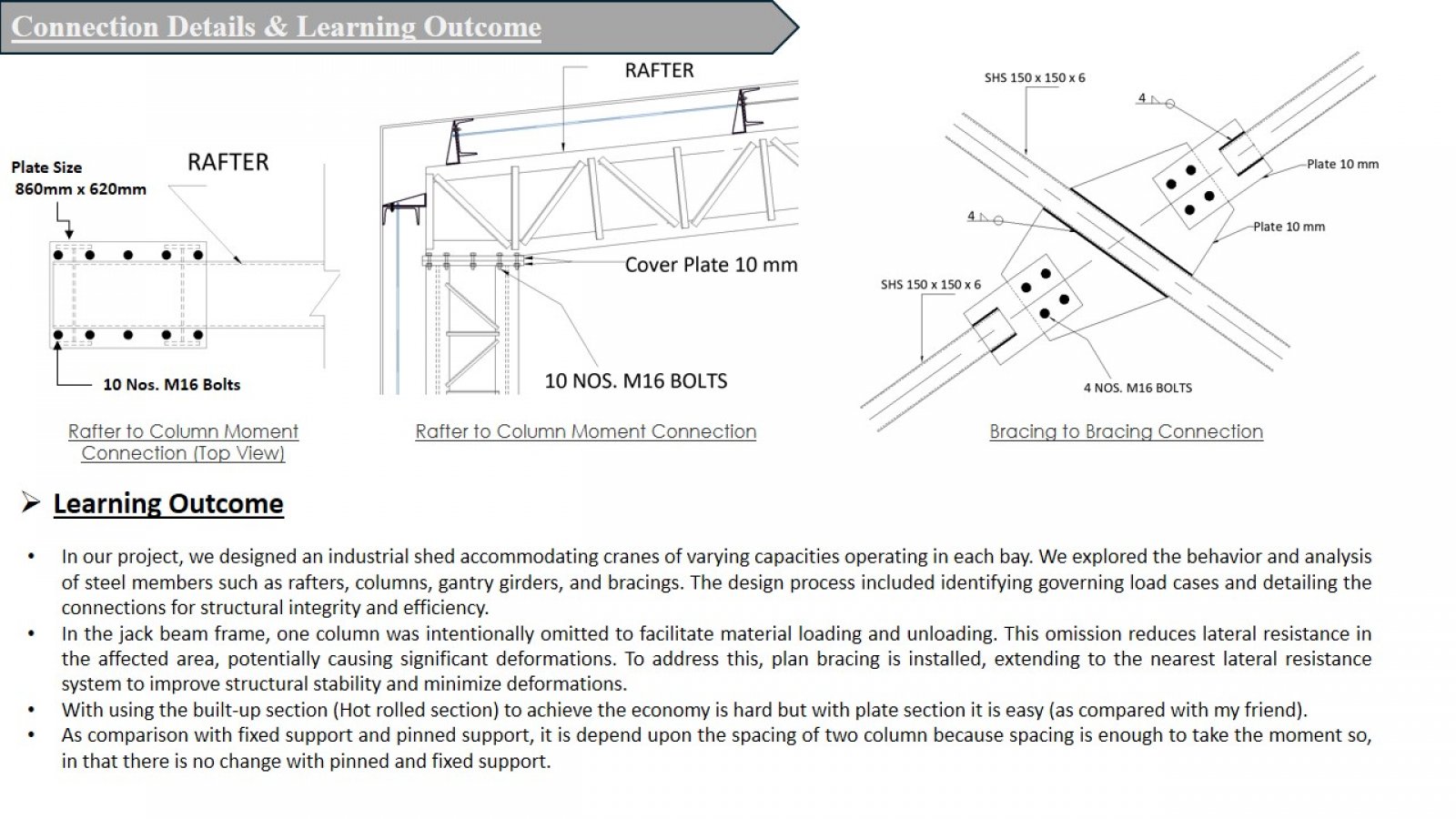

This project involves the construction of a specialized steel pipe manufacturing facility designed to produce giant steel pipes using the spiral method. The plant requires a robust and spacious infrastructure to accommodate the large-scale production process, which includes handling massive pipes and operating heavy lifting machinery. The facility is characterized by its extensive length, essential for housing large gantry systems that facilitate the movement and assembly of steel pipes. To meet the structural demands, the building is constructed using built-up sections made from hot-rolled steel, ensuring durability, load-bearing capacity, and efficiency in supporting the heavy machinery and production operations.

View Additional Work